Metal complex and organic electroluminescent device

A metal complex, metal technology, applied in the direction of electric solid devices, electrical components, luminescent materials, etc., can solve the problems of reducing the quantum yield and molecular stability of the phosphorescent system, poor color purity, and aggravating the quenching of phosphors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0110] The metal complex of the present invention is prepared by using the modified aryl ketone as a raw material and undergoing preparation processes such as ring closure and coordination under suitable conditions. The simple organic preparations involved in the preparation of the metal complexes of the present invention are not described in detail in the present invention.

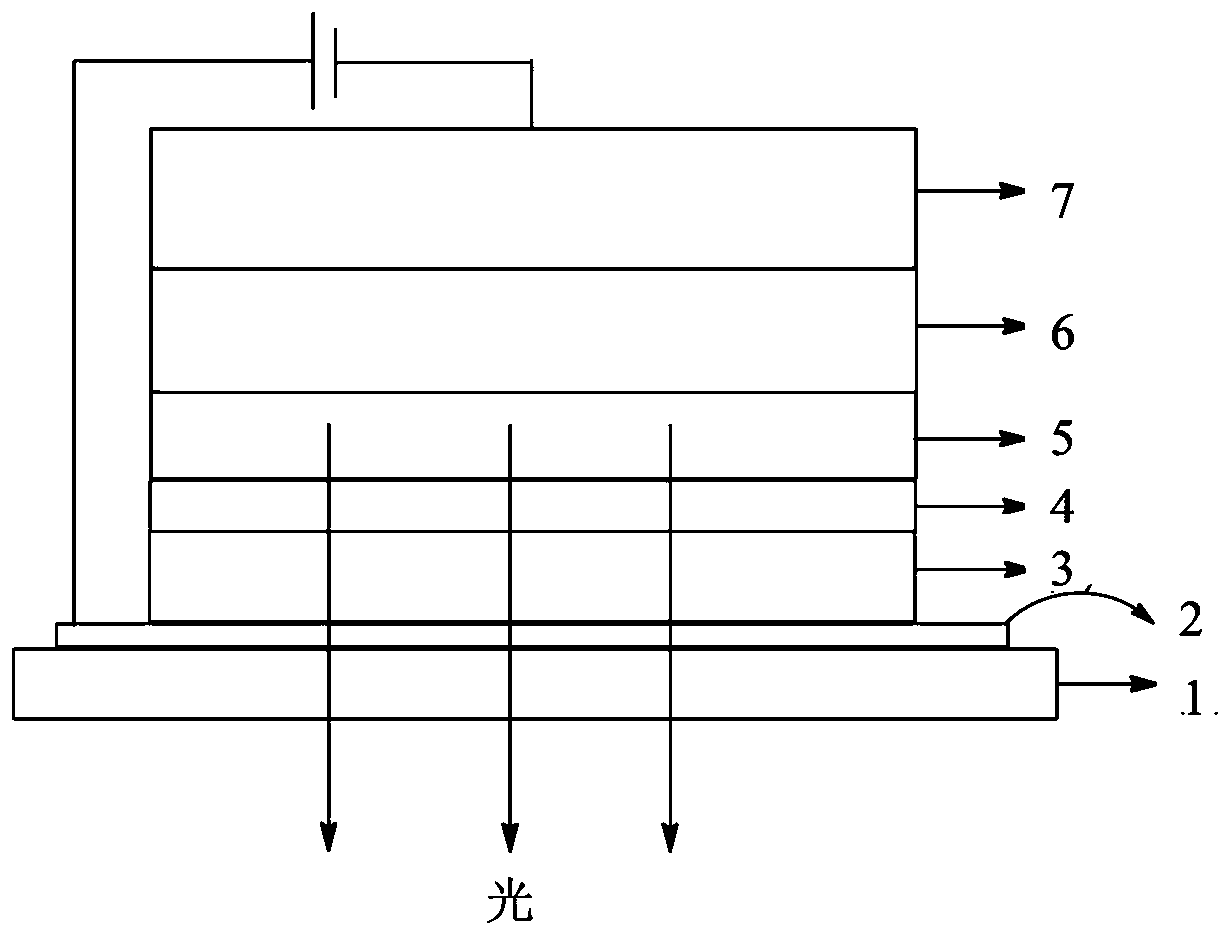

[0111] [Organic Electroluminescent Materials]

[0112] The organic electroluminescent material of the present invention contains one or more of the metal complexes of the present invention. The organic electroluminescent material of the present invention may consist of only one or more of the metal complexes of the present invention, or may contain other materials other than the metal complexes of the present invention.

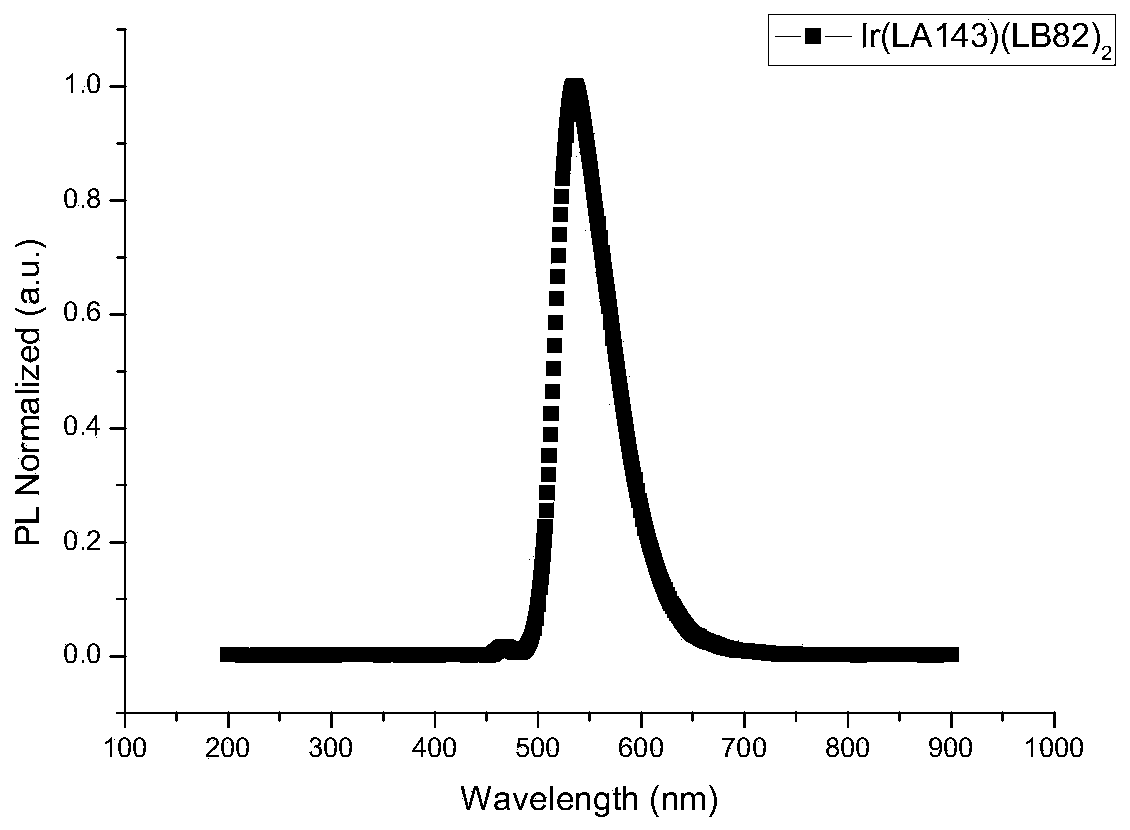

[0113] The metal complex of the present invention is also included in the scope of the present invention as a luminescent material alone or as a dopant material in a luminescent materi...

Embodiment 1

[0139] Preparation of compound LA2:

[0140] The preparation method of ligand LA2 comprises the following steps:

[0141] The first step: preparation of compound Int-1

[0142]

[0143] 61.5g (0.11mol) of 2-iodobenzyltriphenylphosphonium salt was dispersed in 350mL of anhydrous THF. Under nitrogen protection, the temperature was lowered to 0°C with an ice-salt bath, and 14.8g (0.13mmol) of t- Potassium butoxide, after stirring and reacting for 30 minutes, add 20.0g (0.1mol) of 2-bromo-5-methylbenzaldehyde dropwise, after the addition, keep stirring and react for 1 hour, rise to room temperature and stir for 24 hours, add 150mL Saturated ammonium chloride aqueous solution, extracted with ethyl acetate, the organic phase was dried with anhydrous sodium sulfate, filtered, concentrated under reduced pressure to dryness, separated and purified by silica gel column to obtain 36.7g of yellow oil, which was a cis / trans mixture, and the yield : 92%.

[0144] The second step: the ...

Embodiment 2

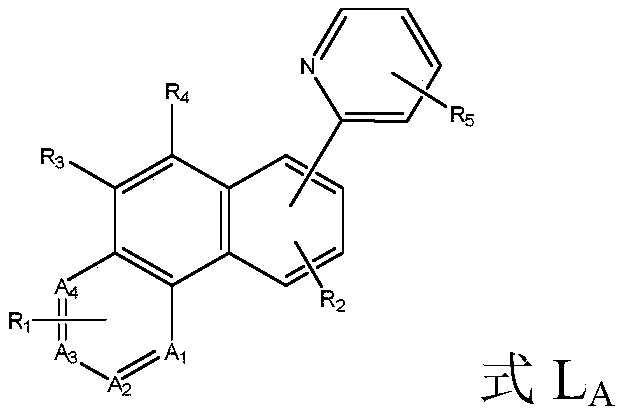

[0154] Preparation of Compound LA143:

[0155] In the single-port reaction flask, drop 5.0g (18.5mmol) of LA2, add 20mL of deuterated ethanol, then add 6.4g (93.0mmol) of sodium ethylate, heat up and reflux for 48 hours, cool to room temperature, and concentrate to dryness under reduced pressure. Separation and purification with a silica gel column yielded 4.8 g of compound LA143 as a yellow solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com