Preparation method of 2-fluoro-1, 3-propanesulfonic acid lactone

A propane sultone and strong acid technology, applied in the direction of organic chemistry, can solve the problems of difficult separation and purification of intermediates or products, poor thermal stability of propane sultone, poor reaction site selectivity, etc. Side effects, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In order to solve the above problems, the first aspect of the present invention provides a method for preparing 2-fluoro-1,3-propane sultone, the steps comprising:

[0033] (1) Sulfonation reaction: carry out a substitution reaction with a sulfite aqueous solution and the reactant (I) in the presence of a phase catalyst to obtain compound (II), or further acidify with a strong acid to obtain compound (III);

[0034] (2) Cyclization reaction: react the compound (II) or compound (III) obtained in step (1) with a dehydrating agent, remove the dehydrating agent after the reaction, wash and extract the reaction solution, remove the solvent, and then Purification by distillation under reduced pressure and recrystallization to obtain the product (IV), namely 2-fluoro-1,3-propane sultone;

[0035] The reactant (I) is a halogenated fluoropropanol, and the general structural formula is: X means Cl, Br, I;

[0036] The compound (II) is 2-fluoro-3-hydroxypropanesulfonate, and it...

Embodiment 1

[0080] Example 1 provides a method for preparing 2-fluoro-1,3-propane sultone, the synthesis reaction formula is as follows:

[0081]

[0082] Preparation steps include:

[0083] (1) Synthesis of sodium 2-fluoro-3-hydroxypropanesulfonate

[0084] Add 62.15 grams of sodium sulfite to 310.75 grams of water, stir to dissolve, then add 1.24 grams of tetrabutylammonium bromide, raise the temperature to 50°C-55°C, add 94.09 grams of 2-bromo-3-fluoropropanol dropwise under stirring, and add dropwise The time is 40-60 minutes. After the dropwise addition is completed, the temperature is kept at 50°C-55°C overnight, and the reaction is lowered to room temperature. Add 35 grams of methyl tert-butyl ether for extraction, and the obtained aqueous phase is dehydrated under reduced pressure and dried at 80°C to obtain a solid crude product 157 grams (semi-dry product), this solid does not need to be refined, and is directly subjected to the next reaction.

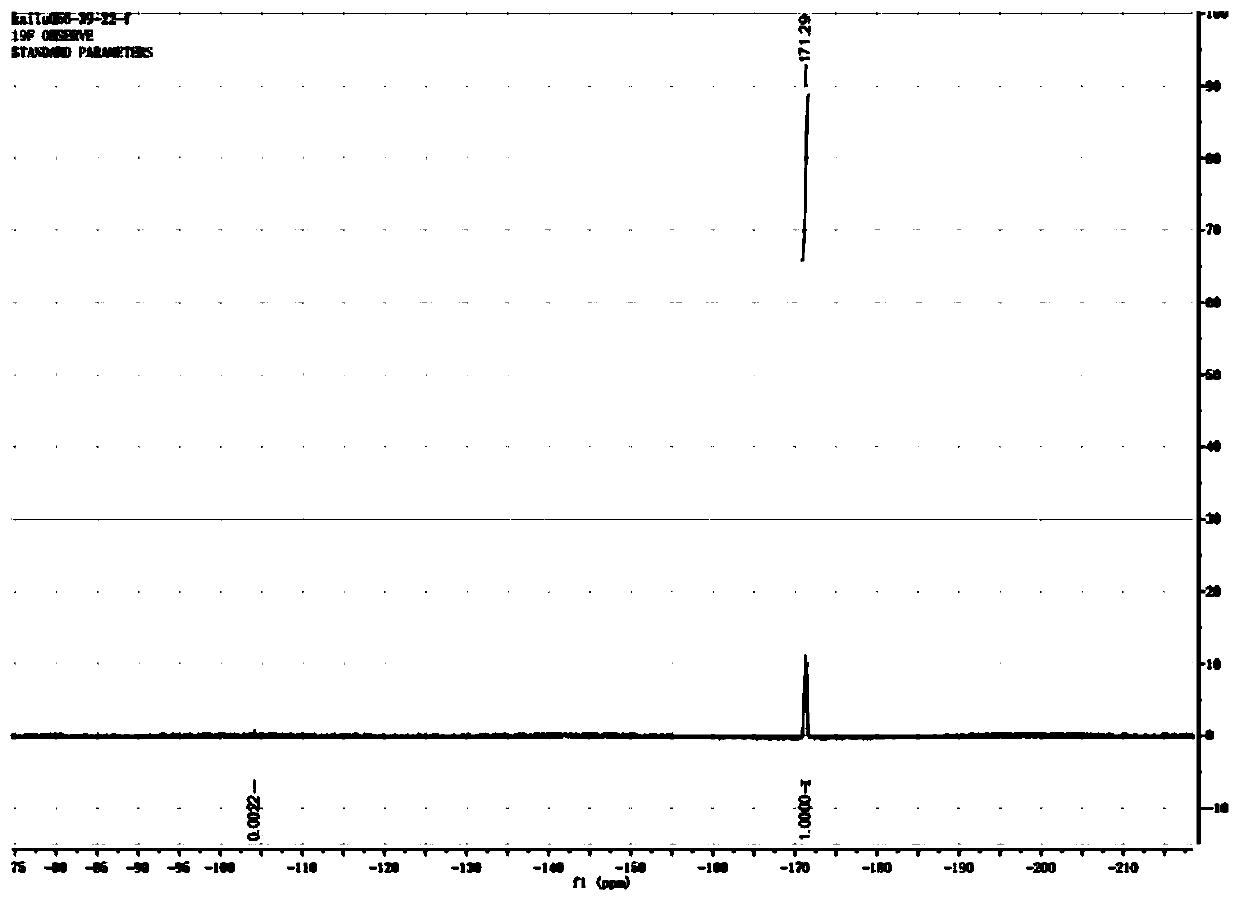

[0085] Spectrum characteriza...

Embodiment 2

[0100] Example 2 provides a method for preparing 2-fluoro-1,3-propane sultone, the synthesis reaction formula is as follows:

[0101]

[0102] Preparation steps include:

[0103] (1) Synthesis of sodium 2-fluoro-3-hydroxypropanesulfonate

[0104] Add 62.15 grams of sodium sulfite to 310.75 grams of water, stir to dissolve, then add 1.24 grams of tetrabutylammonium chloride, add 66.61 grams of 2-chloro-3-fluoropropanol dropwise under stirring, dropwise for 40-60 minutes, add dropwise After completion, the temperature was raised to reflux for overnight reaction. The reaction liquid was lowered to room temperature, and 35 g of methyl tert-butyl ether was added for extraction. The obtained aqueous phase was dehydrated under reduced pressure and dried at 80° C. to obtain 88.95 g of a crude solid product, which was directly subjected to the next reaction without purification.

[0105] (2) Synthesis of 2-fluoro-1,3-propane sultone

[0106] Weigh 577 grams of phosphorus oxychlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com