Glass fiber texture clamping manipulator for laying fan blades

A technology for fan blades and manipulators, applied in textiles and papermaking, spreading thin soft materials, cutting textile materials, etc., can solve the problems of strong dependence, no production of fan blades, low efficiency of manual spreading, etc. The use of manpower and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

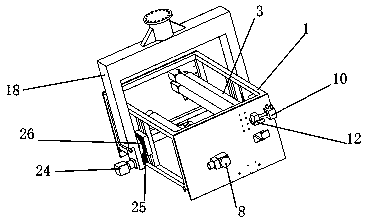

[0017] Please combine figure 1 , figure 2 , image 3 It is understood that a manipulator for clamping glass fiber fabrics used for fan blade layup finishes loading the glass fiber fabrics on the manipulator hanging roller 2, and then the hanging roller 2 is fixed on the base 1 through the locking disc 17, The fiberglass fabric that unfolds passes through the gap between the upper compression shaft 4, the upper compression shaft 5 and the upper compression shaft 3, and then enters the gap between the lower compression shaft 6 and the lower compression shaft 7, and the preparatory work ends. Then the servo motor 8 works, drives the material hanging roller 2 to rotate, and the fiberglass fabric continues to unfold along with the rotation to carry out the laying of the fan blades; Guide rail 11 and guide rail 12 move close to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com