Metering type material feeding device

A material distribution device and material technology, which is applied in packaging, solid materials, loading/unloading, etc., can solve the problems of complex quantitative feeding control, etc., and achieve the effects of reducing impact force, ensuring rationality, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

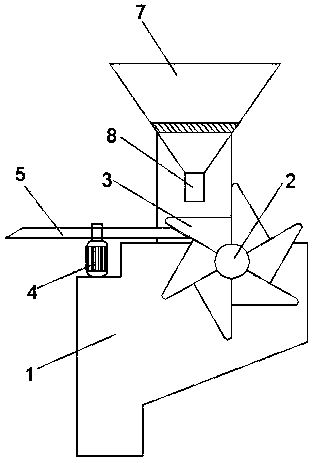

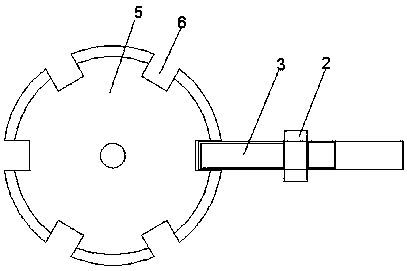

[0014] Below in conjunction with specific embodiment, content of the present invention is described in further detail: as Figure 1-2 As shown, a metering material unloading device includes a material box 1, a material distribution device connected to the material box 1, a limit device, and a hopper 7 fixed on the upper end of the material box 1; wherein the material distribution device includes 1. The rotating shaft 2 at the upper end of the inner wall, and a plurality of distributing trays 3 fixed in a circular array on the side wall of the rotating shaft 2; The limit device includes a motor 4 fixed on the material box 1 and a limit plate 5 connected to the motor 4; a number of grooves 6 are distributed in a ring on the side of the limit plate 5, and the width of the groove 6 is the same as that of the distribution plate 3 along the axis of rotation. The width in the direction of the central axis is the same; the hopper 7 is an inverted conical structure with a discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com