On-line cutting equipment for heat preservation pipe production

A technology for insulation pipes and cutting equipment, which is applied in metal processing and other directions, and can solve problems such as cutting insulation pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

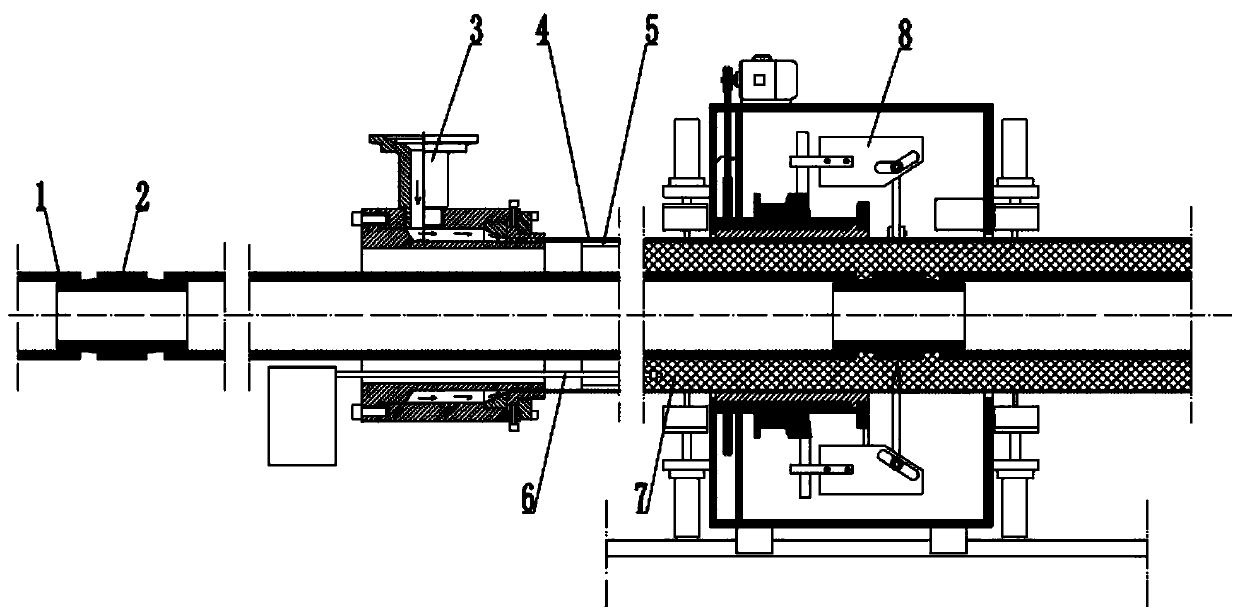

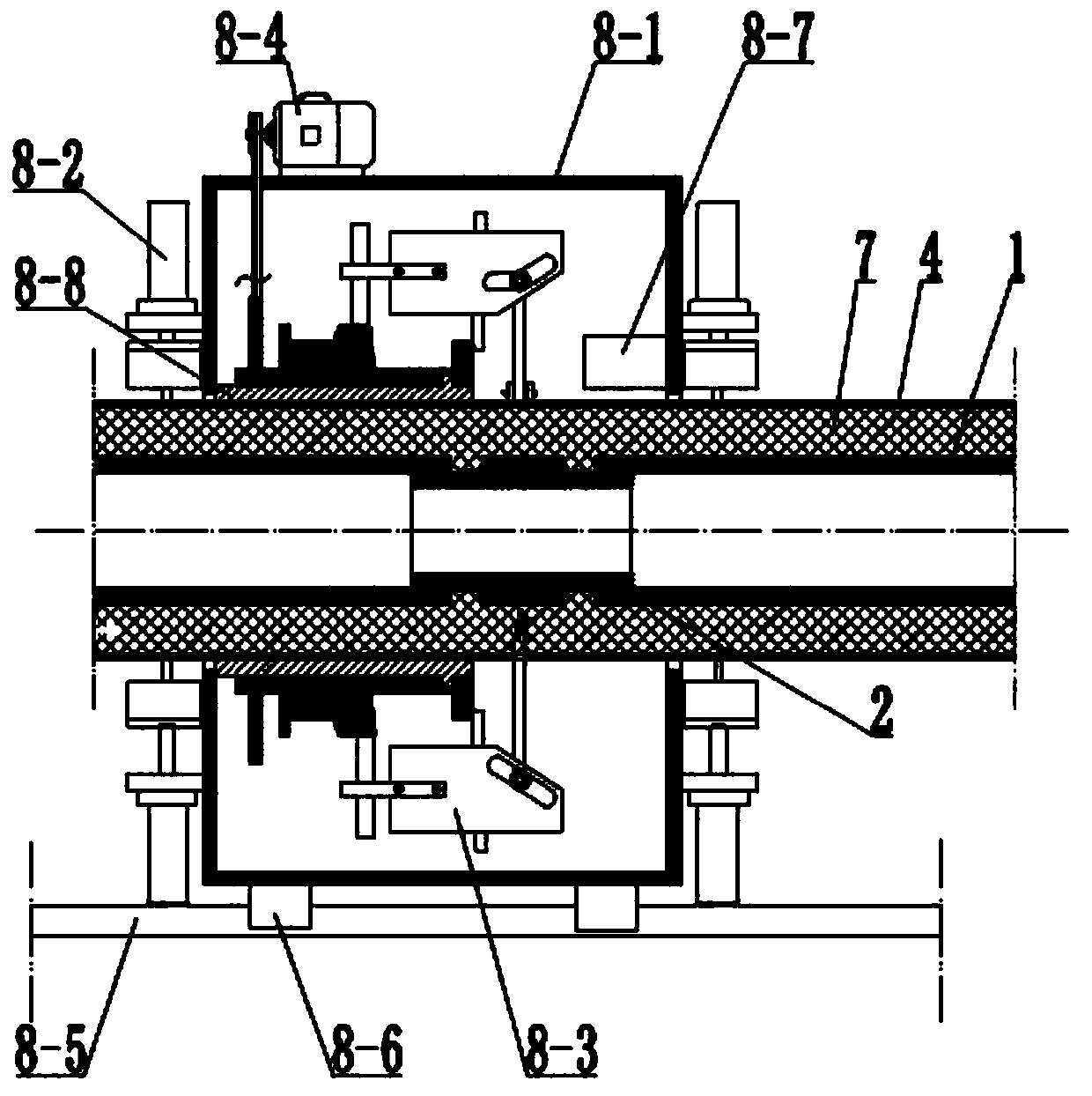

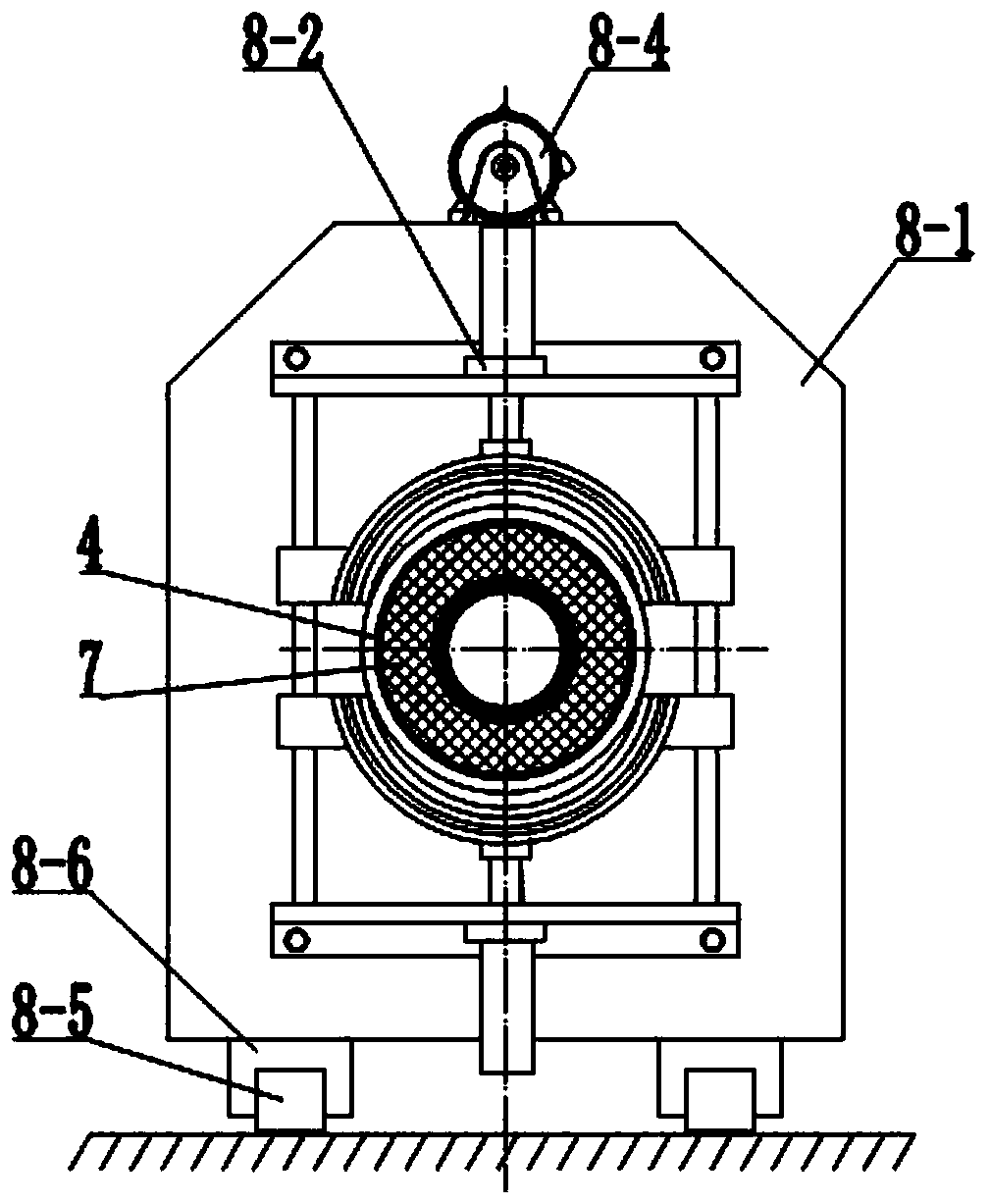

[0028] see figure 1 , in the one-step forming process of the insulation pipe, in order to ensure the continuous supply of the steel pipe 1, it is necessary to connect the two sections of the steel pipe 1 through the non-metallic plug joint 2; then the steel pipe 1 enters the plastic extrusion under the push of the conveying device. The central hole at the machine head 3, when the steel pipe 1 protrudes from the other side of the central hole to the designed length, the plastic extruder extrudes the outer protective tube 4, and the outer protective tube 4 coaxially surrounds the steel tube 1 and is connected to the steel tube 1 moves forward synchronously at a uniform speed, during which the sizing and corona treatment are performed on the inner surface of the outer protective pipe 4 through the sizing die 5; during the synchronous progress of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com