Intelligent tightening tool and intelligent management method

A tightening tool and intelligent technology, applied in the direction of motor tools, manufacturing tools, non-electric variable control, etc., can solve the problems of low precision, no guarantee of quality, intelligence, informationization, and lack of high-precision control fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

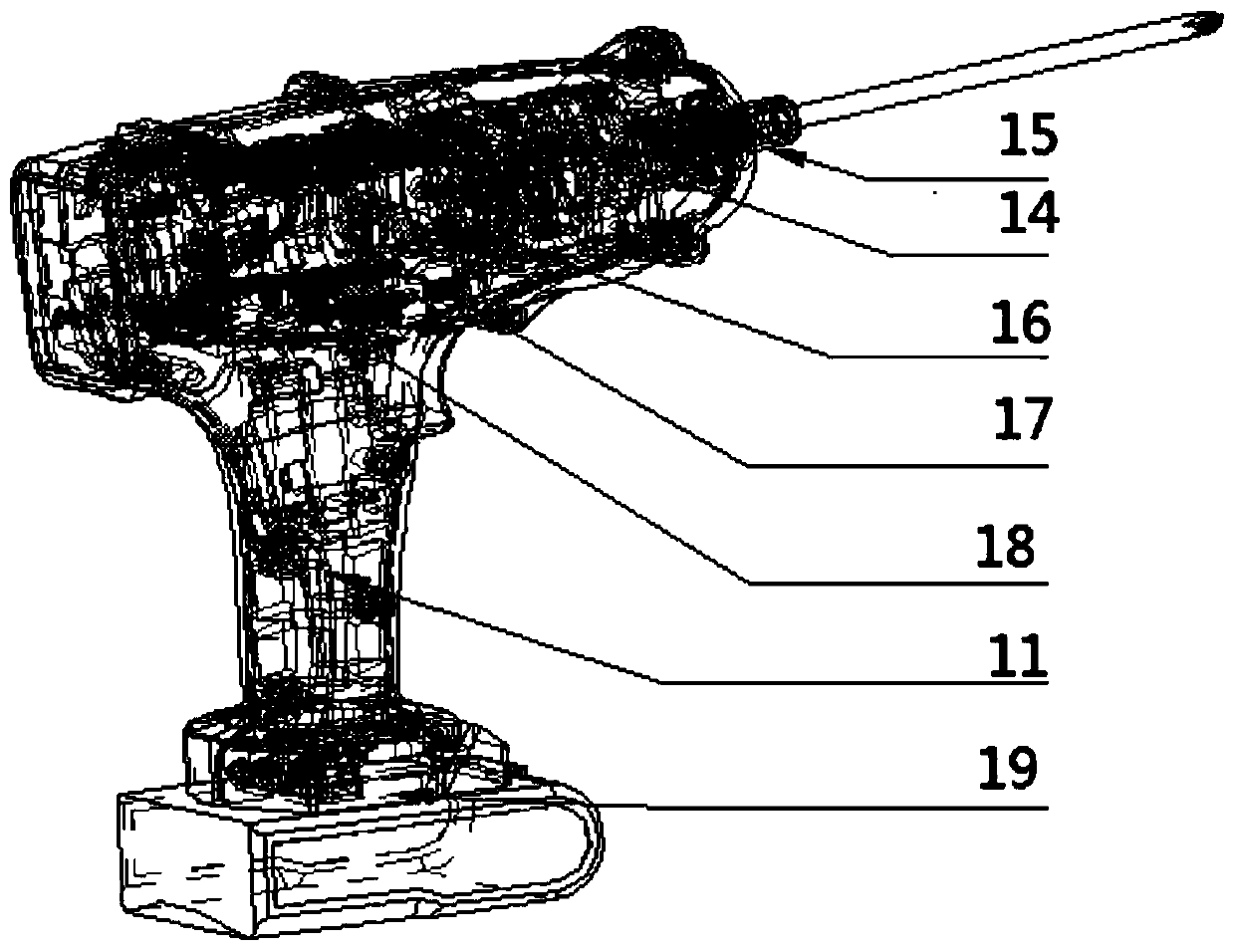

[0038] see figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 , figure 1 It is a structural diagram of the intelligent tightening tool of the present invention, figure 2 It is a three-dimensional view of the internal structure of the intelligent tightening tool of the present invention, image 3 It is a structural diagram of the tightening power structure of the intelligent tightening tool of the present invention, Figure 5 It is the left view of the tightening power structure of the intelligent tightening tool of the present invention, Figure 6 It is a top view of the tightening power structure of the intelligent tightening tool of the present invention; in this embodiment, an intelligent tightening tool includes a tool body 11, a tightening power structure 17 arranged on the upper part of the tool body 11, accommodated inside the tool body 11 and The main control structure component 18 that calibrates and records the position of the working process by ident...

Embodiment 2

[0055] This embodiment discloses a torque control drive mechanism vector control method,

[0056] see Figure 15 and Figure 16 , Figure 15 It is a schematic diagram of the FOC torque control algorithm of the intelligent tightening tool of the present invention; Figure 16 It is a segmented tightening control strategy diagram of the intelligent tightening tool of the present invention; in this embodiment, the torque detection device adopts the FOC control algorithm to apply to the torque control of the brushless coreless geared motor, adopts the optimal torque control strategy, monitors the feedback tightening parameters in real time, and outputs Tightening curves and test results for visualization and parametric quality monitoring.

[0057] The method includes:

[0058] Gather the two-phase current of the motor drive control structure 16

[0059] Transformed quadrature current quantity;

[0060] Controlling the DC flow of these two variables;

[0061] Send the two var...

Embodiment 3

[0067] see Figure 18 , Figure 18 It is a database workflow flow chart of the intelligent tightening tool of the present invention. This embodiment discloses an intelligent management method for an intelligent tightening tool, which provides an authority management module, a parameter setting module, a database storage module, and a database. The user data, wiring equipment data and template data are saved and regularly updated. The image acquisition module scans the equipment code and cable number and sends the scanned equipment code and cable code to the image processing module. The image processing module Algorithms are used to match the scanned image with the barcode or equipment code in the database. If the match is successful, the tightening power structure starts to run at the installation position. If the match fails, the image acquisition module continues to scan the information of the equipment. The above database interacts with the server at any time for user dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com