Automobile back door built-in tooling structure

An automotive back door, built-in technology, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems affecting customers' evaluation of the appearance of the model, high quality parts requirements, and different adjustment states of the back door. The effect of shortening manual assembly adjustment man-hours, reducing parts accuracy requirements, and reducing the amount of manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

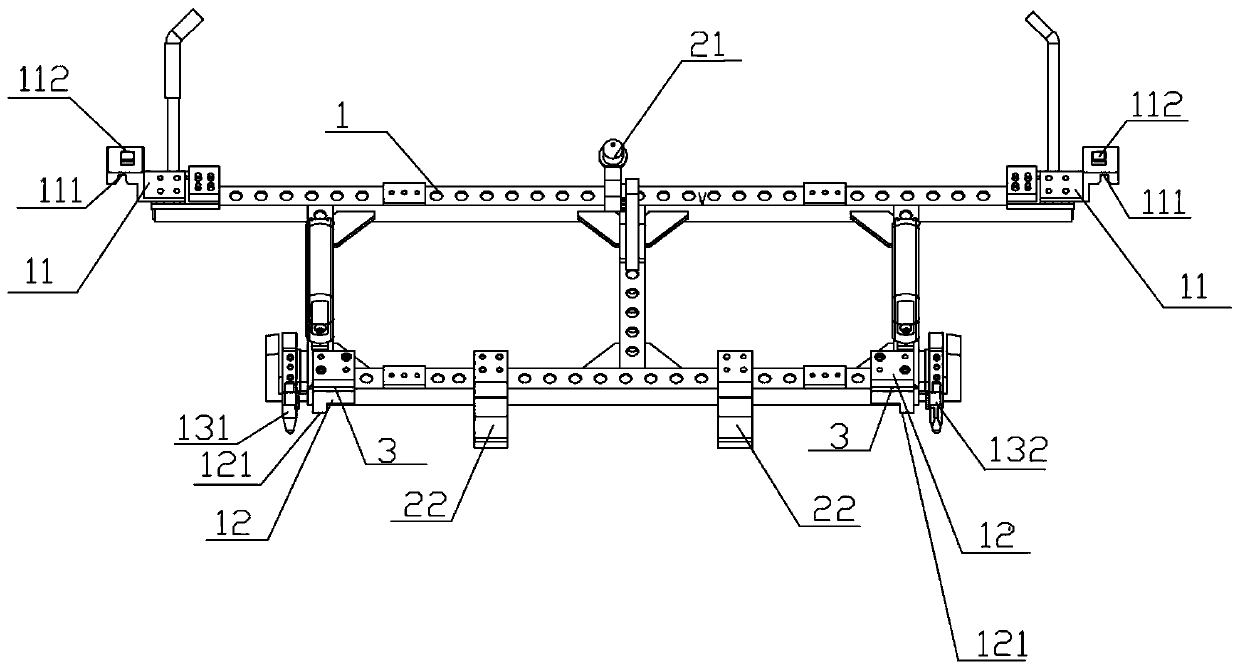

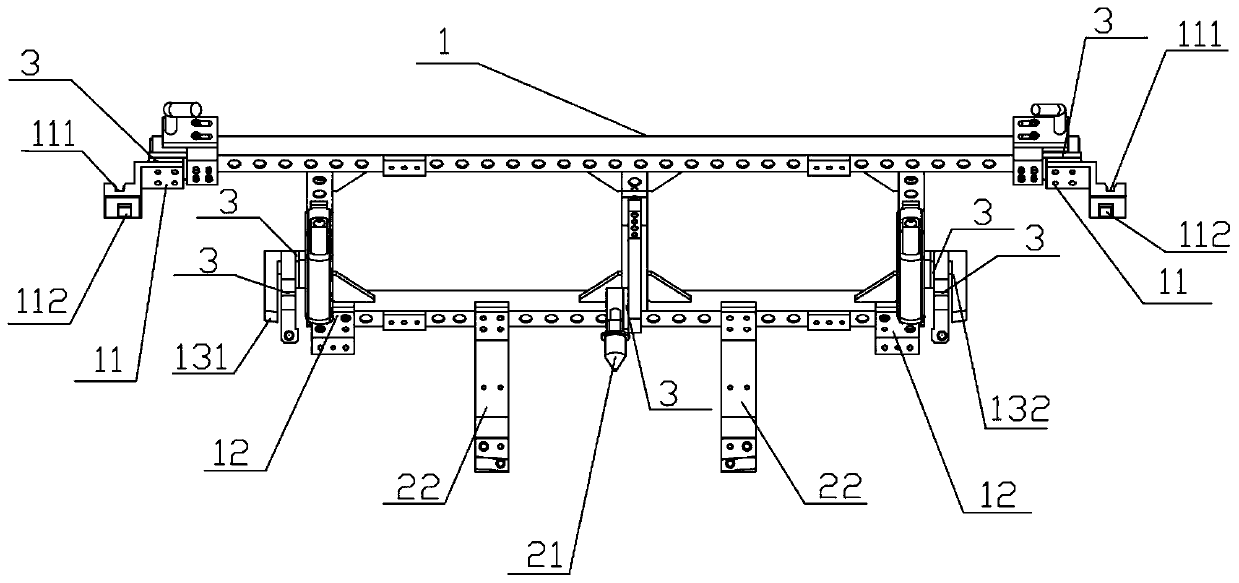

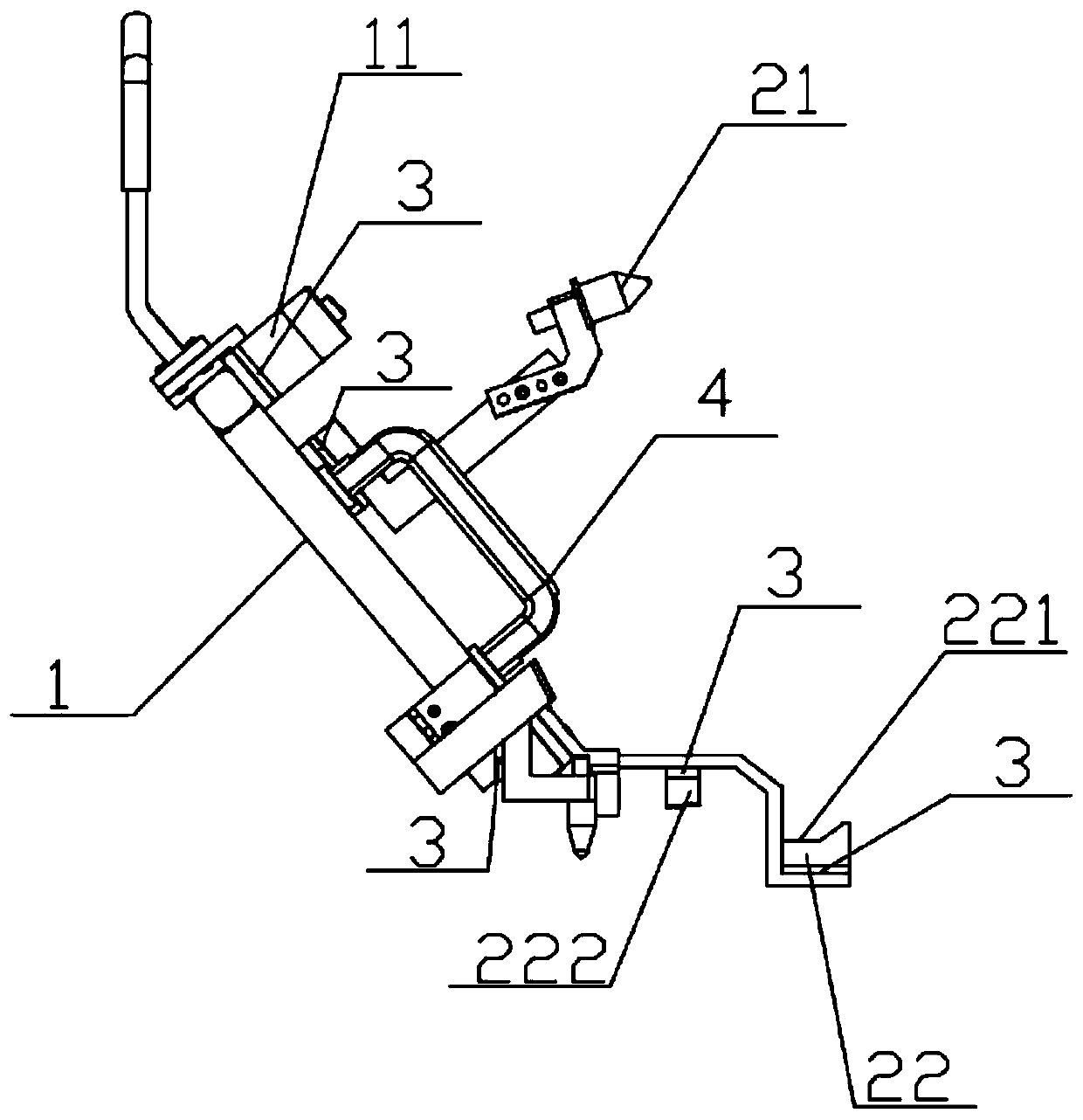

[0030] Such as figure 1 , figure 2 , image 3 As shown, a vehicle back door built-in tooling structure includes a tooling frame 1; the tooling frame 1 is provided with a first positioning assembly for positioning with the vehicle body and a second positioning assembly for positioning with the back door;

[0031] Wherein, the second positioning assembly includes the back door Y direction positioning pin 21 fixed on the width direction of the tooling frame 1 and the back door Z direction positioning block 22 fixed on the tooling frame 1 length direction, the back door Y direction positioning pin 21 and the back door The corresponding Y-direction positioning holes are connected, and the Z-direction positioning block 22 of the back door includes a Z-direction positioning surface 221 of the back door, and the Z-direction positioning surface 221 of the back door is attached to the corresponding reference surface on the back door; perpendicular to each other.

[0032] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com