Dietary fiber yogurt with high fat taste and preparation method thereof

A dietary fiber and high-fat technology, which is applied in the field of food manufacturing, can solve the problems of weak industrialization of citrus peel fiber extraction, and achieve the effects of stable texture, production cost saving, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

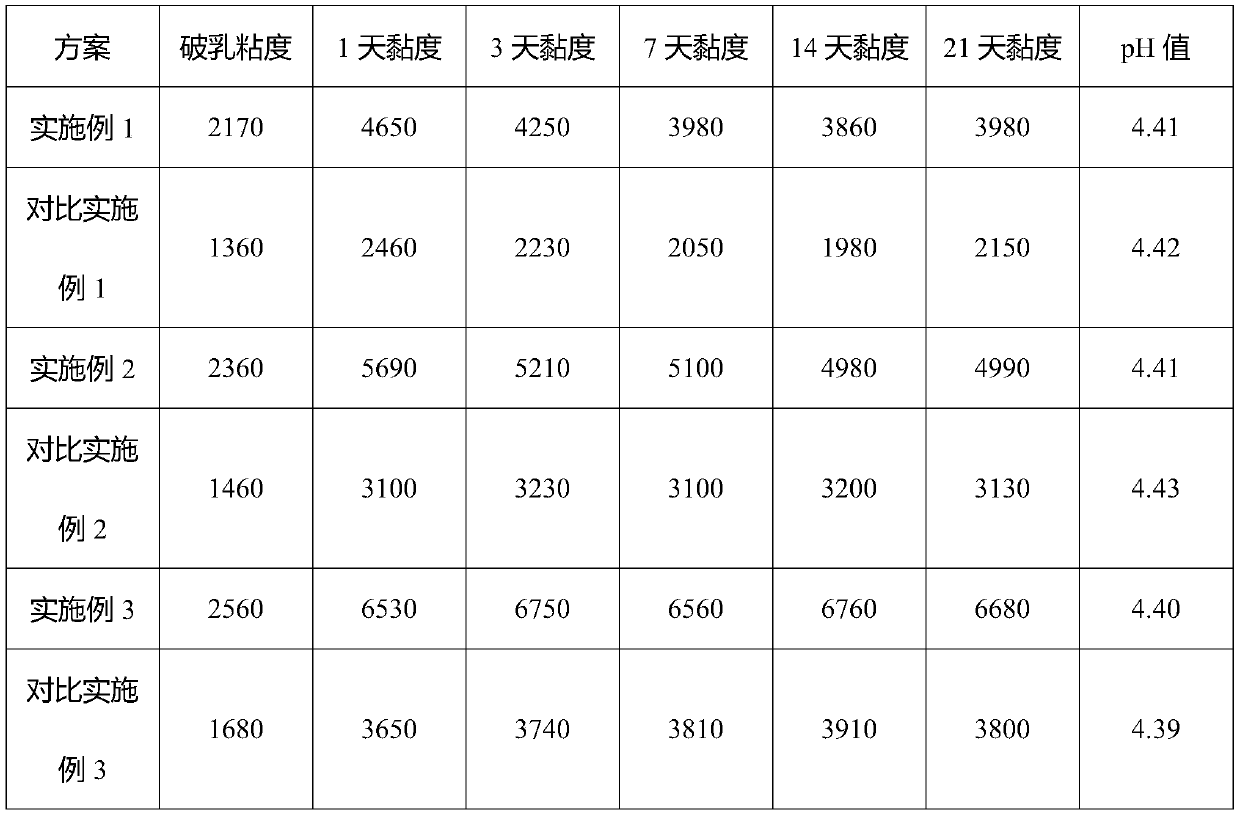

Examples

Embodiment 1

[0023] The dietary fiber yoghurt with a high-fat mouthfeel is composed of raw materials by mass percentage: 4% cream, 8% white sugar, 1.5% polydextrose, 0.04% citrus fiber, 0.06% starter, and raw milk as the balance.

[0024] The starter is a mixed starter, specifically including Lactobacillus bulgaricus and Streptococcus thermophilus.

[0025] The concrete steps of the preparation method of this yogurt are as follows:

[0026] A. Carry out standardized pretreatment of raw milk to make standardized raw milk with a milk protein content of 2.9-3.5% and a milk fat content of 4.0-5.0%;

[0027] B. Control the temperature of the chemical material to 80°C, add cream, white sugar, polydextrose, and citrus fiber to the standardized raw milk, put the mixed material into a shear tank and mix and stir for 20 minutes to obtain a mixed solution;

[0028] C. Control the temperature of the mixed solution to 65°C, and homogeneously refine it under the primary pressure of 18Mpa and the second...

Embodiment 2

[0037] Fat index A dietary fiber yogurt with a high-fat taste. The raw materials are calculated by mass percentage: 6.0% cream, 8% white sugar, 1.5% polydextrose, 0.06% citrus fiber, 0.06% starter, and the balance is raw milk .

[0038] The starter is a mixed starter, specifically including Lactobacillus bulgaricus and Streptococcus thermophilus.

[0039] The concrete steps of the preparation method of this yogurt are as follows:

[0040] A. Carry out standardized pretreatment of raw milk to make standardized raw milk with a milk protein content of 2.9-3.5% and a milk fat content of 4.0-5.0%;

[0041] B. Control the temperature of the chemical material to 82°C, add butter, white sugar, polydextrose, and citrus fiber to the standardized raw milk, put the mixed material into a shear tank and mix and stir for 20 minutes to obtain a mixed solution;

[0042] C. Control the temperature of the mixed liquid to 55°C, and homogeneously refine it under the primary pressure of 20Mpa and...

Embodiment 3

[0050] The dietary fiber yoghurt with high-fat mouthfeel is composed of the following mass percentages: 8.0% butter, 8% white sugar, 1.5% polydextrose, 0.08% citrus fiber, 0.06% starter, and raw milk as the balance.

[0051] The starter is a mixed starter, specifically including Lactobacillus bulgaricus and Streptococcus thermophilus.

[0052] The concrete steps of the preparation method of this yogurt are as follows:

[0053] A. Carry out standardized pretreatment of raw milk to make standardized raw milk with a milk protein content of 2.9-3.5% and a milk fat content of 4.0-5.0%;

[0054] B. Control the temperature of the chemical material to 85°C, add cream, white sugar, polydextrose, and citrus fiber to the standardized raw milk, put the mixed material into a shear tank and mix and stir for 20 minutes to obtain a mixed solution;

[0055] C. Control the temperature of the mixed solution to 60°C, and homogeneously refine it under the primary pressure of 25Mpa and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com