Dust discharge centrifugal ventilator with automatic adjusted tension

A technology of centrifugal dust removal and automatic adjustment, applied in the direction of machine/engine, mechanical equipment, transmission device, etc., can solve the problems of falling, low efficiency, belt slippage, etc., and achieve the effect of convenient adjustment and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

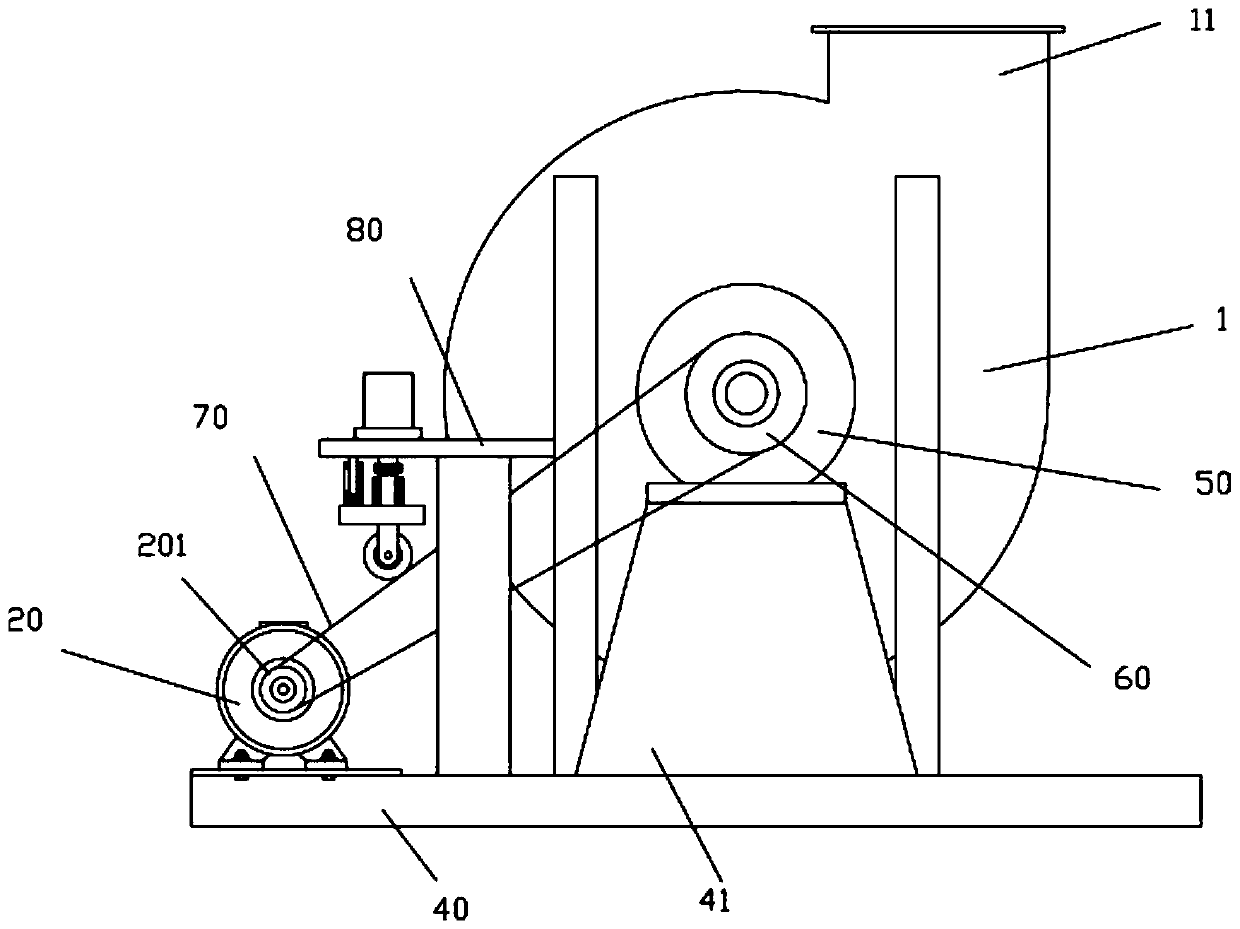

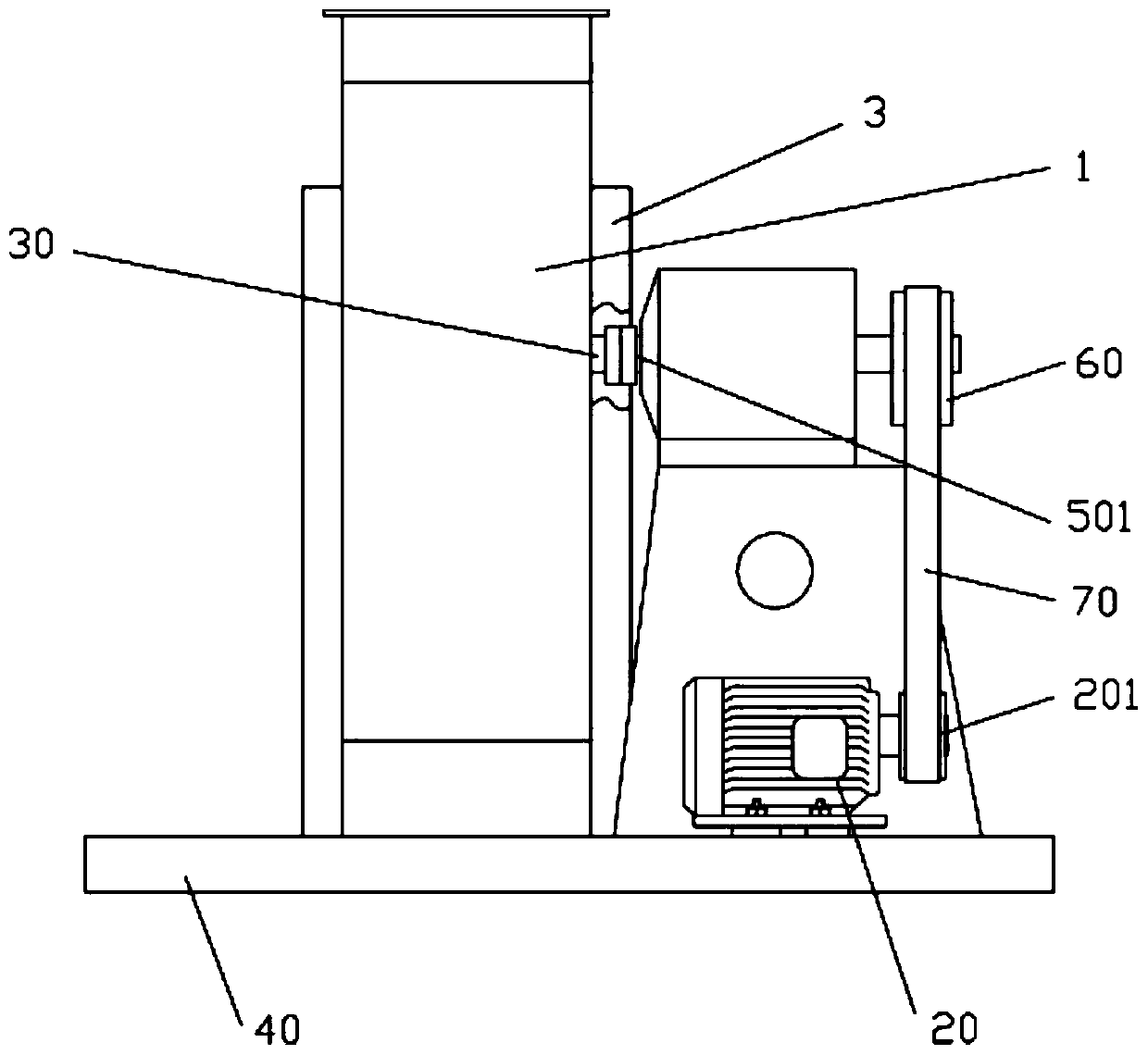

[0018] Example: see Figures 1 to 4 As shown, a dust-exhausting centrifugal fan with automatic tension adjustment includes a volute 1, a motor 20, a rotating shaft 30 fixed with an impeller, and a bottom bracket 40. The volute 1 is fixed on the bottom bracket 40, and the bottom bracket 40 is fixed with a gear box 50, one end of the output shaft 501 of the gear box 50 is connected with the rotating shaft 30 through a coupling, the input shaft of the gear box 50 is fixed with a pulley 60, and the output shaft of the motor 20 is fixed with a drive wheel 201, The belt 70 is tensioned on the belt pulley 60 and the drive pulley 201, the top surface of the main bottom plate 41 of the bottom bracket 40 is fixed with an adjustment support frame 80, and the top surface of the top plate of the adjustment support frame 80 is fixed with a compression adjustment motor 81, which The output shaft of the tight adjustment motor 81 passes through the bottom surface of the top plate of the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com