Anti-sulphuric wear-resistant sucker rod centralizer special for wax removal

A sucker rod and centralizer technology, used in drill pipes, cleaning appliances, drilling equipment, etc., can solve the problems of easy corrosion, oil rod eccentric wear, corrosion, nylon wear quickly, etc., to achieve fiber flexibility and fatigue resistance. , The effect of enhanced high temperature corrosion resistance and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

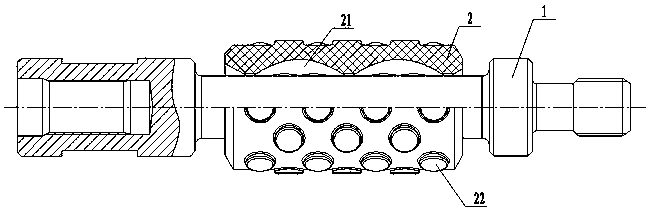

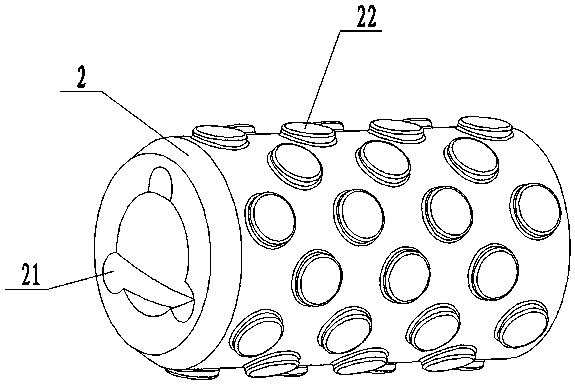

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 , figure 2 As shown, the special sucker rod centralizer for anti-sulfur, wear-resistant and wax removal includes: a metal rod body 1 and a cylindrical synthetic centralizer 2 rotatably arranged on the metal rod body 1, and the inner wall of the cylindrical synthetic centralizer 2 is evenly Three internal diversion spiral flow holes 21 are provided, and several cylindrical flat bosses 22 are uniformly arranged on the outer surface of the cylindrical composite centralizer 2 .

[0013] In this embodiment, the cylindrical synthetic centralizer 2 is made by compounding injection molding of high molecular weight polyethylene and carbon fiber. A wear-resistant and anti-oxidation metal powder coating is provided on the surface of the metal rod body 1 .

[0014] The above-mentioned sucker rod central...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com