Low-noise small size frog using single moving nose rail

A low-noise, heart-rail technology, applied in the direction of track, switch, road, etc., can solve the problem of no good solution to the noise of harmful space parts of frogs, and achieve the elimination of gauge line discontinuity, noise reduction, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

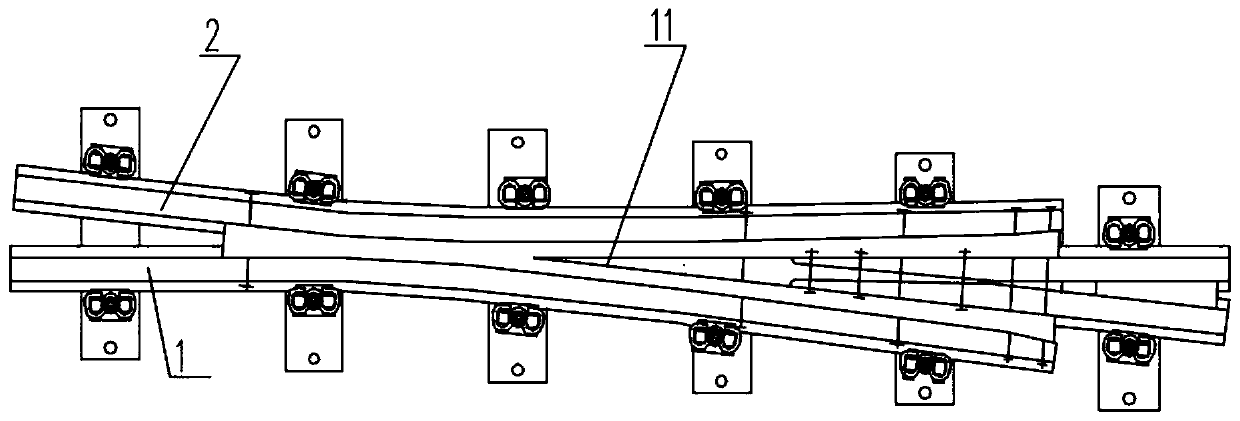

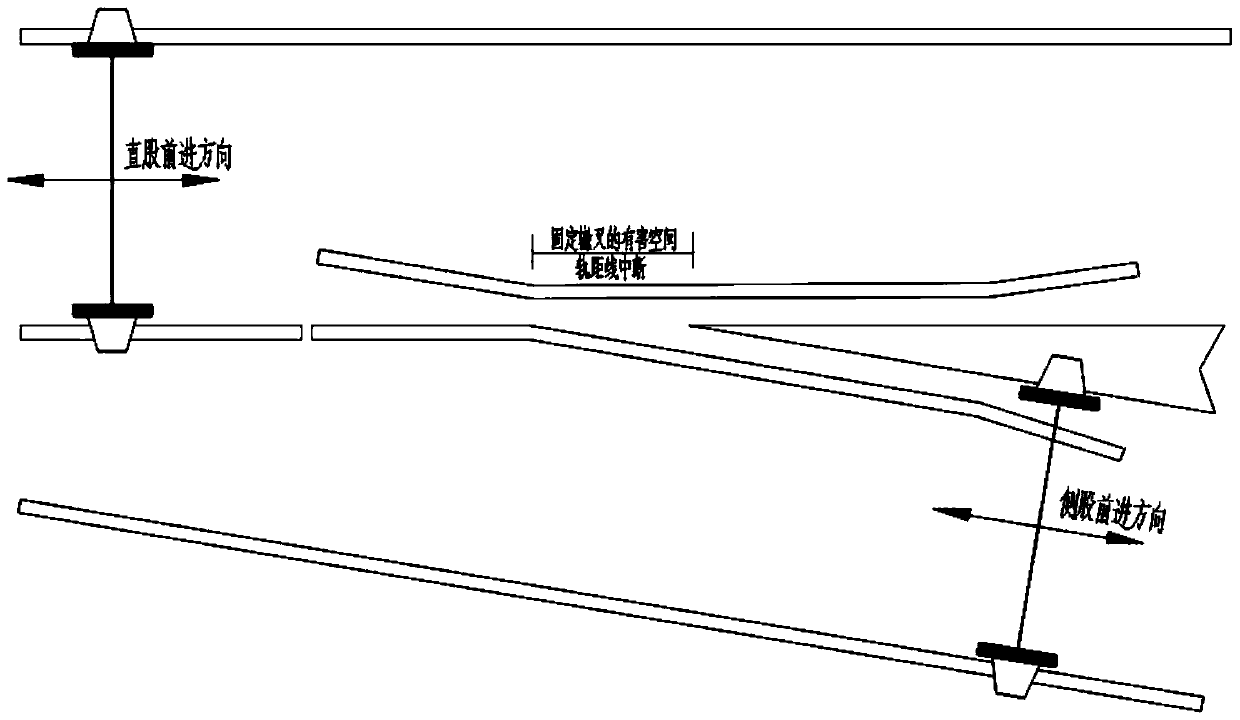

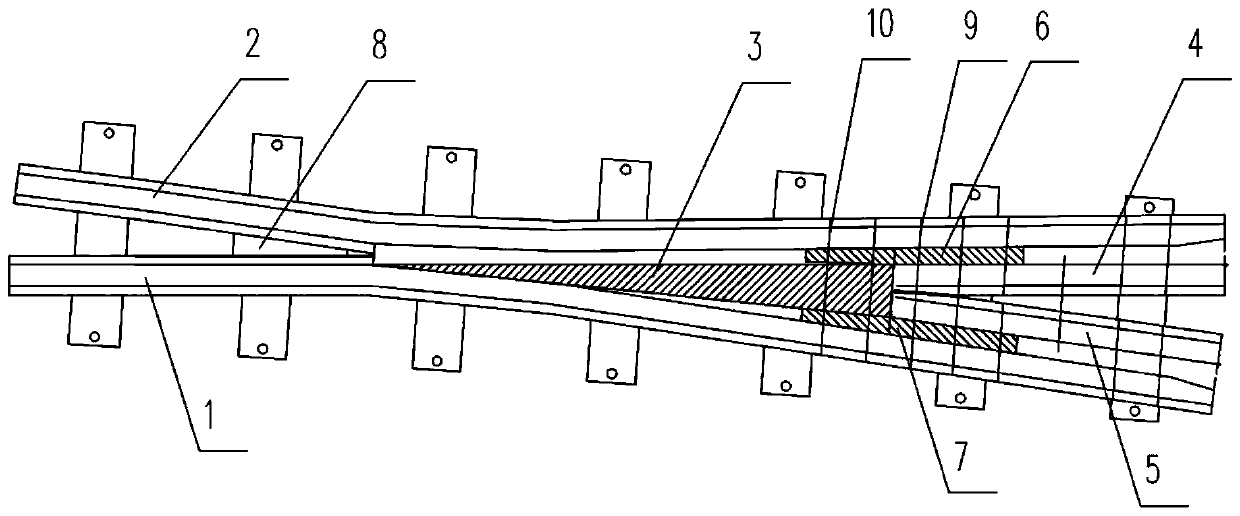

[0027] The low-noise small number frog that uses the single movable core rail provided in the present invention comprises two wing rails (side wing rail 1 and straight strand wing rail 2, wing rail spacing iron 8 and two wing rail spacing irons 8 and two Fork heel rails (straight stock fork heel rail 4 and side stock fork heel rail 5) connected at the ends; a wedge-shaped movable core rail 3 is provided between the wing rail throat and the fork heel rail. The tip of the movable core rail 3 It is located at the throat of the wing rail (towards the junction of the two wing rails), and the bottom is against the ends of the two fork and heel rails (both are flat).

[0028] The frog also includes two straight stock spacer irons 6 and side stock spacer irons 7 located on the outside of the fork heel rail and the movable core rail 3; The wing rails 2 are in close contact with each other, and the rear portion of the side stock spacer iron 7 is in close contact with the side stock fork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com