Nut processing and blackening treatment equipment for easy transportation

A technology of blackening and nut, applied in the direction of metal material coating process, etc., can solve the problems of affecting the efficiency of blackening processing and hindering the ferric oxide layer, and achieve the effect of improving stability and reliability and ensuring processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

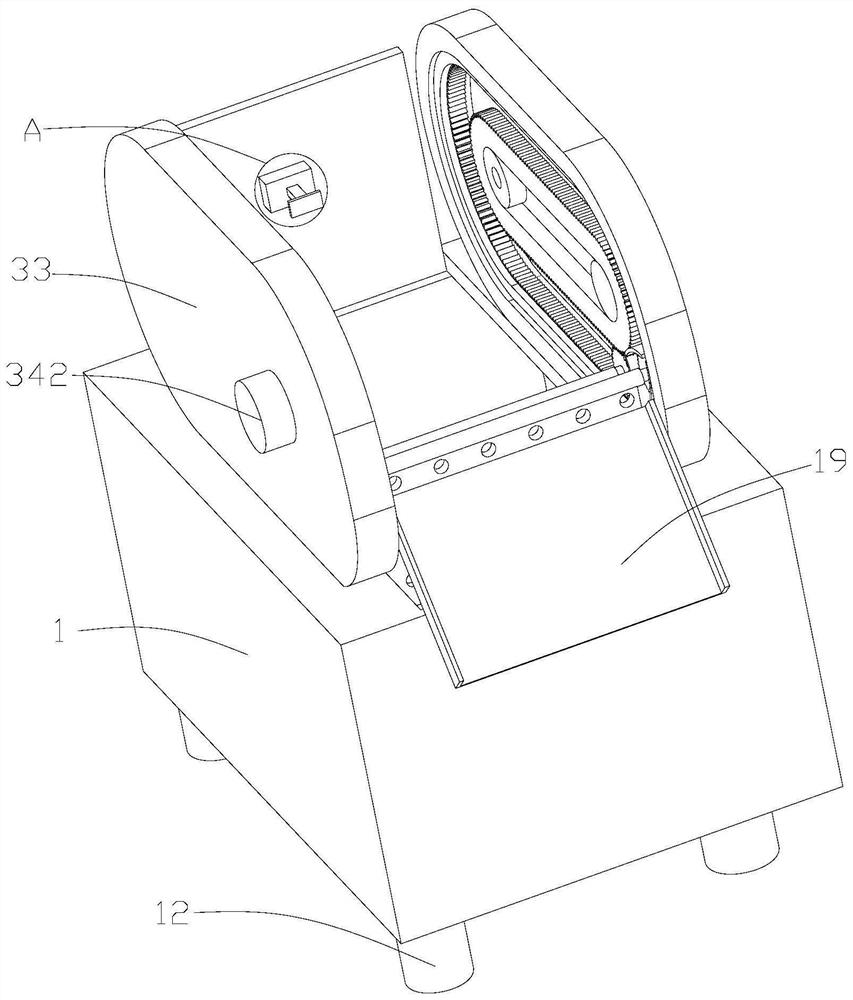

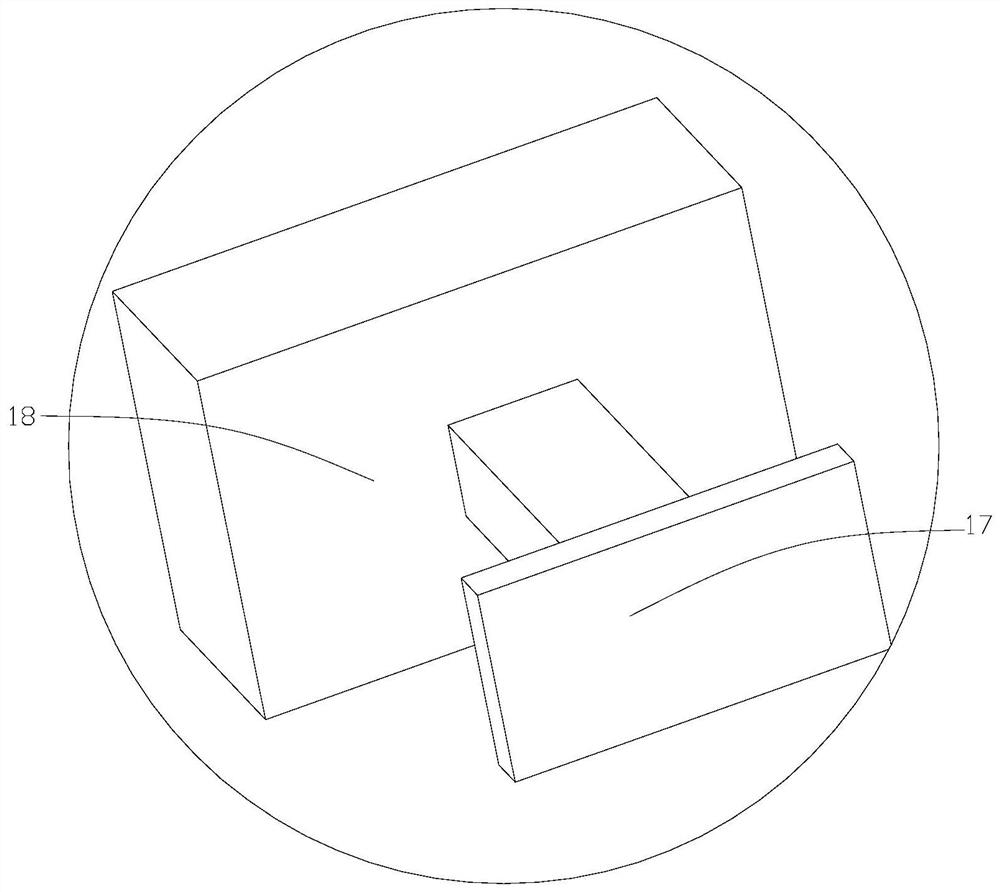

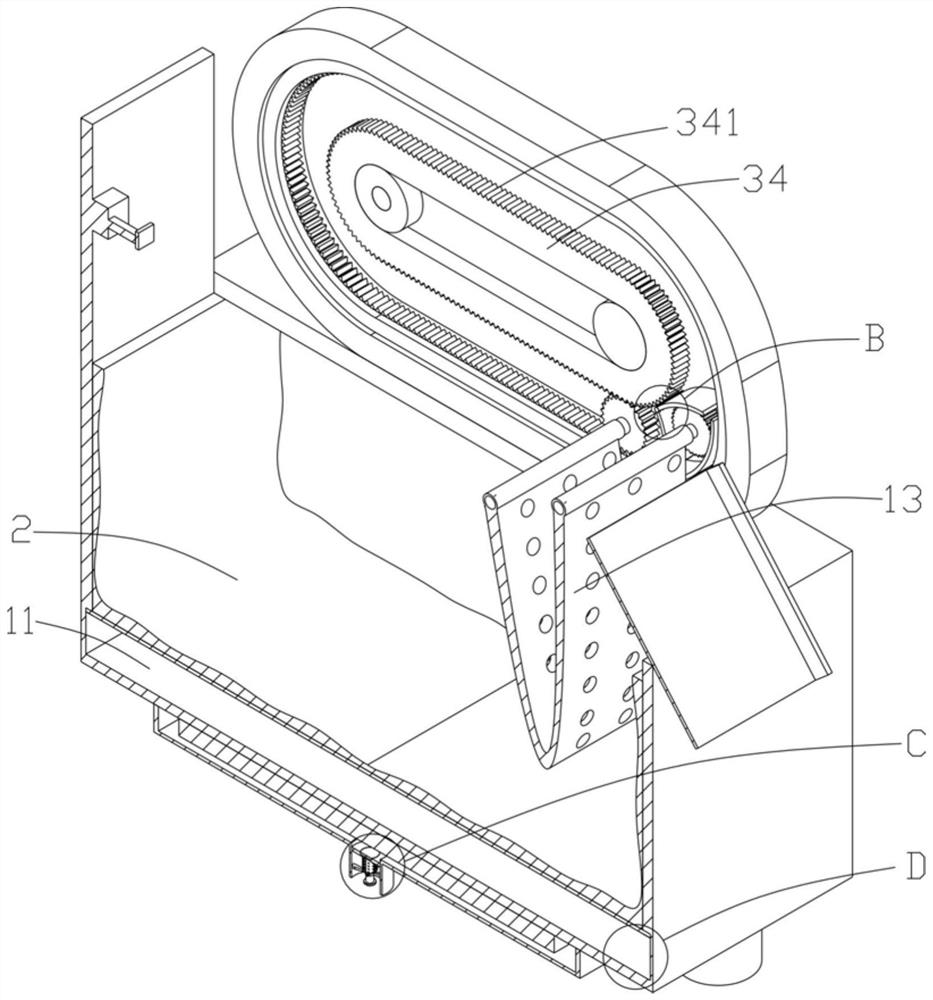

[0029] Such as Figure 1-13 As shown, a nut processing and blackening treatment equipment that is convenient for transportation includes a processing box 1 for supporting and fixing the device, a reaction chamber 11 for the nuts to undergo blackening reaction, and a plurality of supports for supporting the processing box 1 Feet 12, the reaction chamber 11 is provided with a container bag 2 for containing the blackening solution, and the treatment box 1 is provided with a conveying member 13 for controlling the nut to roll and move and two conveying members 13 for driving The driving mechanism for the movement of nuts, through the setting of the above structure, enables batches of nuts to be controlled by the above conveying parts, and realizes the effect of rolling and dipping while moving and conveying, so that batches of nuts can be effectively blackened, avoiding nuts Contact between surfaces leads to incomplete immersion, which effectively ensures the effect of blackening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com