A kind of mechanical parts protective wax and preparation method thereof

A technology for mechanical parts and protective wax, applied in chemical instruments and methods, polishing compositions, coatings, etc., can solve the problems of obvious delamination and poor uniformity, and achieve improved stability, reduced impact, and pure effective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

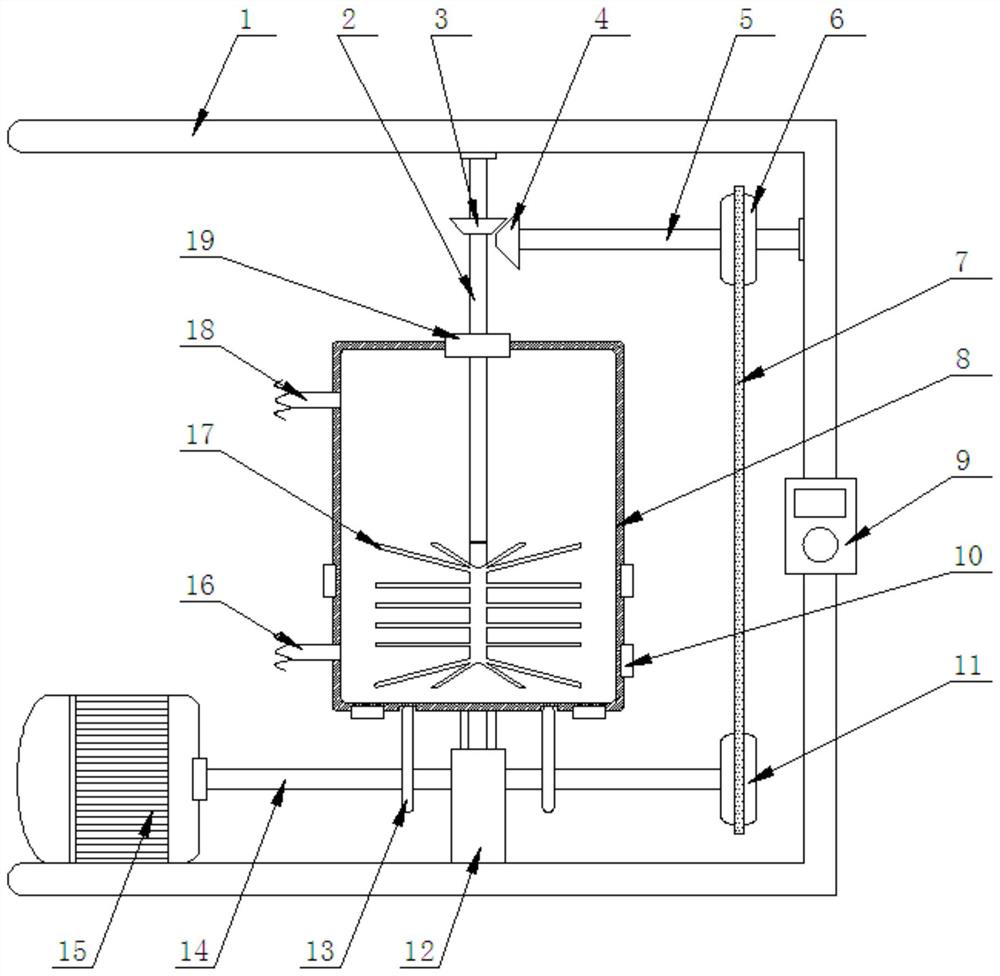

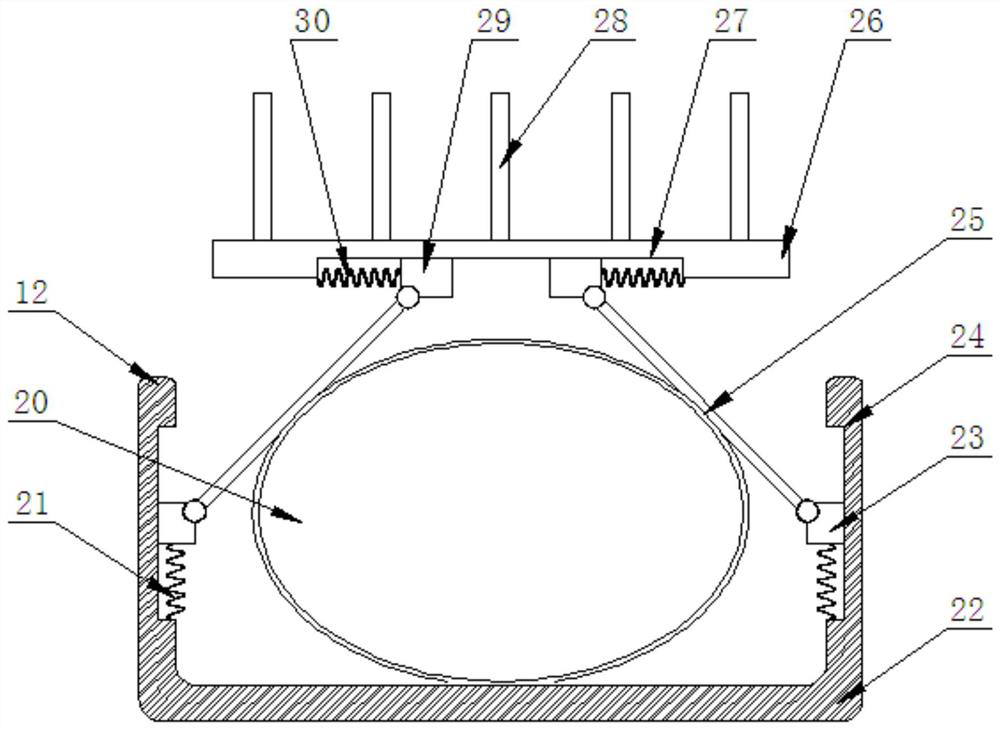

Method used

Image

Examples

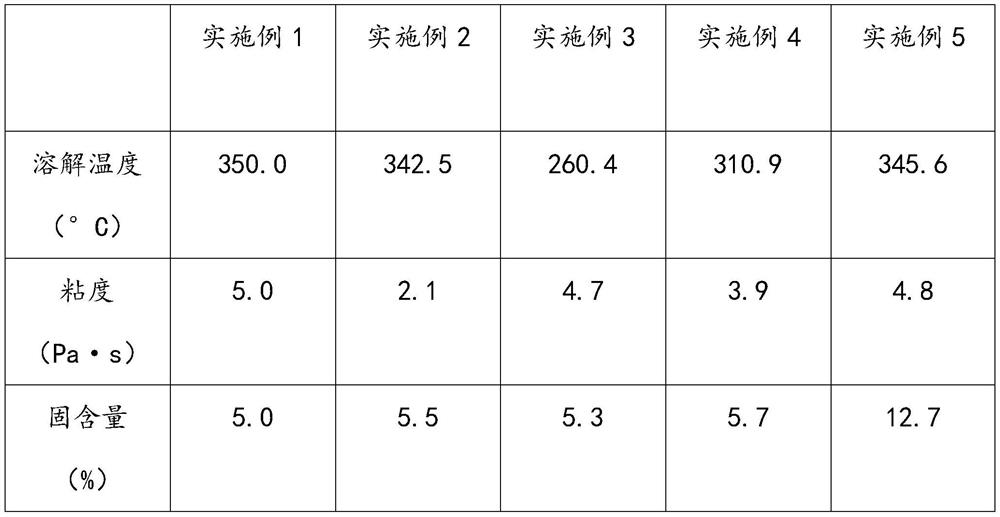

Embodiment 1

[0034] A kind of mechanical parts protection wax, described each raw material is respectively made of 40% solvent, 25% epoxy resin, 15% liquid paraffin, 10% modified curing agent, 5% butyl titanate and 5% nonylphenol polyoxyethylene ether composition;

[0035] The solvent is mixed with ethanol and acetone in a ratio of 4:1;

[0036] The modified curing agent is prepared by the following process: first introduce aniline, formaldehyde and concentrated hydrochloric acid with a concentration of 25% into a stirring tank, and react for 3 hours under heating to 55 degrees, and then neutralize it with sodium carbonate solution And, then introduce ammonia water thereinto, export the mixed solution to the absorption tower after stepwise precipitation, filter and remove impurities, then introduce dilute sulfuric acid with a concentration of 30% into it, and feed phosphine gas at the same time, at a pressure of 1.5 MPa, the temperature is 65 degrees, it is absorbed by the absorption towe...

Embodiment 2

[0043] A kind of protective wax for mechanical parts, the difference from Example 1 is that the modified curing agent is prepared by the following process: first, aniline and formaldehyde are introduced into the stirring tank together, and reacted for 3 hours under heating to 55 degrees , and then use sodium carbonate solution to neutralize it, and then introduce ammonia water into it, after step-by-step precipitation, filter and remove impurities, the mixed solution is exported to the absorption tower, and then introduce dilute sulfuric acid with a concentration of 30% into it. Add phosphine gas, under the pressure of 1.5MPa and temperature of 65 degrees, circulate and absorb in the absorption tower for 2 hours, and recrystallize and purify with deionized water, filter and cool down to obtain the modified curing agent;

[0044] The modified curing agent is composed of 40% formaldehyde, 25% aniline, 20% dilute sulfuric acid and 15% phosphine respectively by weight percentage. ...

Embodiment 3

[0047] A kind of protective wax for mechanical parts, the difference from Example 1 is that the modified curing agent is prepared by the following process: first, aniline, formaldehyde and concentrated hydrochloric acid with a concentration of 25% are introduced into the stirring tank together, Heated to 55 degrees and reacted for 3 hours, then neutralized it with sodium carbonate solution, then introduced ammonia water into it, and after step-by-step precipitation and filtration to remove impurities, the mixed solution was exported to the absorption tower, and then the concentration was 30%. The dilute sulfuric acid is introduced into it, and under the pressure of 1.5MPa and the temperature of 65 degrees, it is absorbed by the absorption tower for 2 hours, and after recrystallization and purification with deionized water, it is filtered and cooled to obtain a modified curing agent;

[0048] The modified curing agent is composed of 37.5% formaldehyde, 22.5% aniline, 22.5% conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com