Full-color shell layer 3D printer based on layer-by-layer light curing and color shell object

A 3D printer, layer-by-layer solidification technology, applied to coating devices, 3D object support structures, processing platforms/substrates, etc., can solve problems such as inability to generate color printed objects, printing speed limitations, and speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0197] [best practice]

[0198] Below in conjunction with accompanying drawing, the present invention will be further described with regard to preferred embodiment:

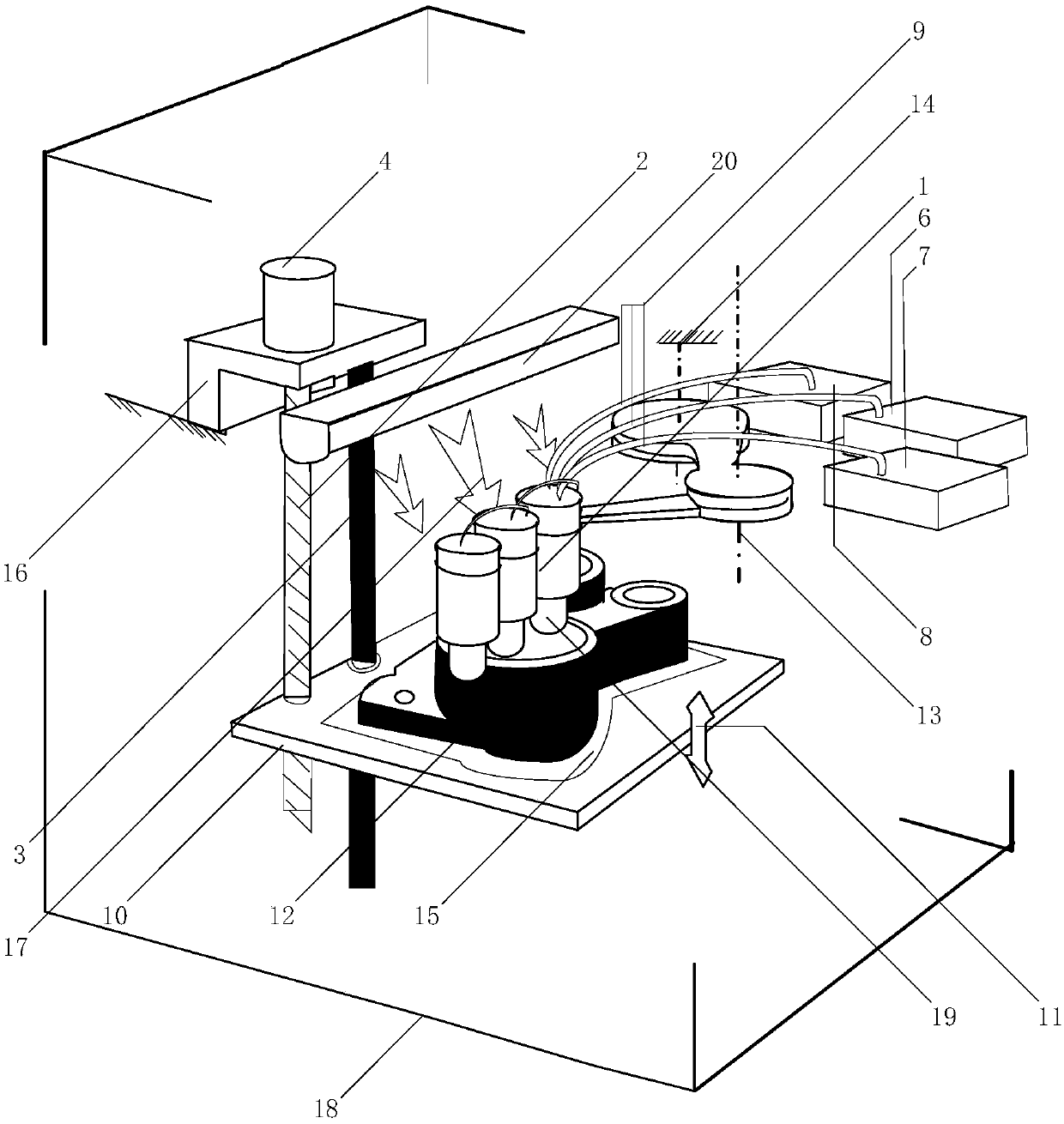

[0199] Such as figure 1 Shown:

[0200] Schematic diagram of the general 3DP (no powder spreading) printer structure on the market at present, the structural feature of the transformation of the present invention is only in the passage of the multi-nozzle print head (1) (which can be integrated, without the need for separate ink delivery pipes and ink storage boxes) Color ink storage cartridge (6) has been added in: it is different from the printing method and program.

[0201] Other basic structures are: the Z-axis motor (4) drives the lead screw (2) to make the vertical displacement of the lifting platform (10) under the constraint of the guide cylinder (3), as shown in the direction of lifting movement (11); the multi-nozzle printing The horizontal plane displacement of the head (1) is generated by coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com