Welding technology for single-surface welding and double-surface forming

A technology of double-sided molding and welding process, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of increasing welding difficulty, low efficiency, and incomplete penetration of the back, so as to reduce welding difficulty and improve weld seam quality, avoiding the effect of incomplete penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

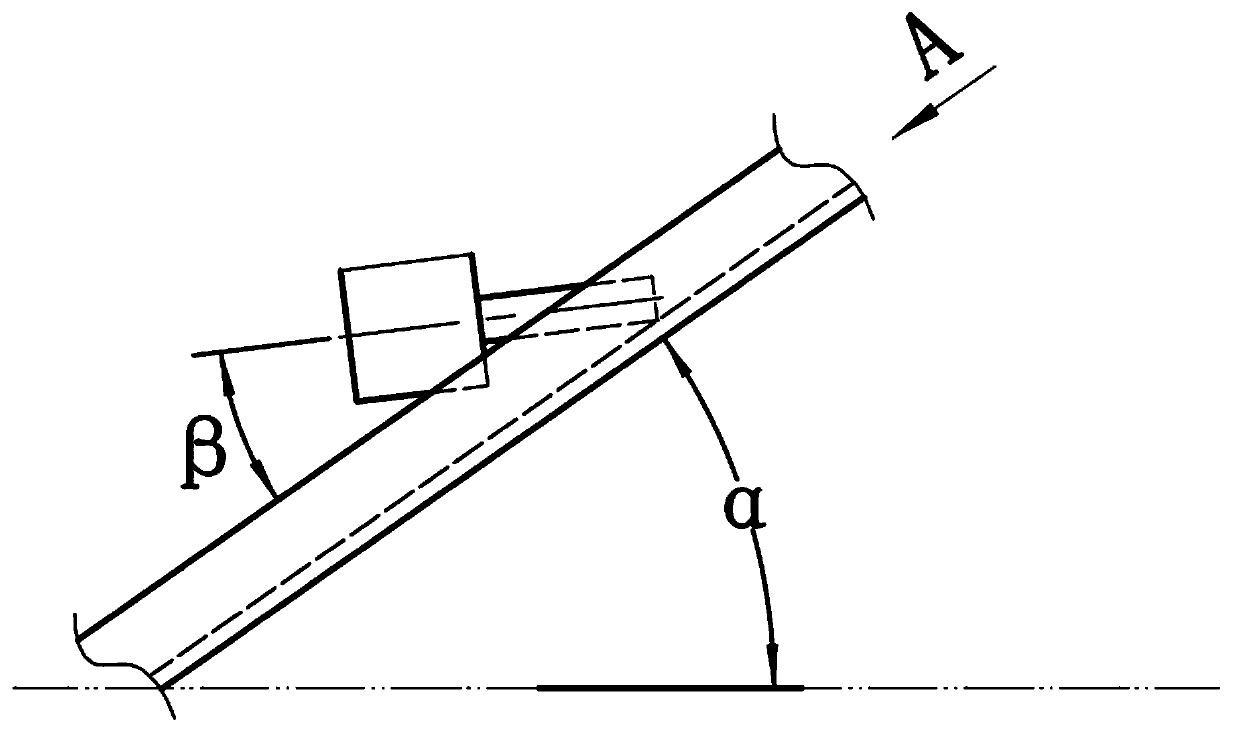

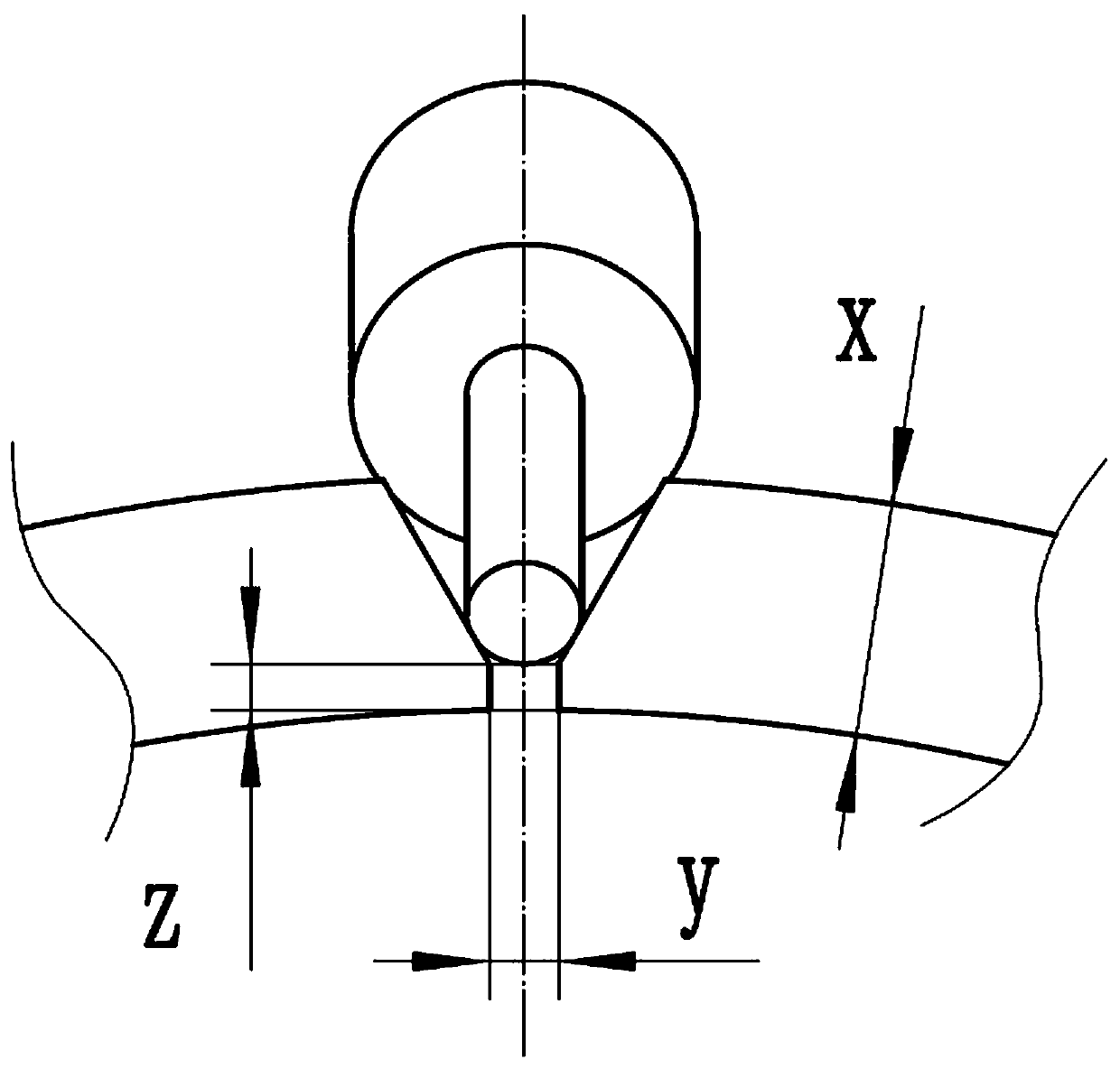

[0024] Such as figure 1 and 2 , a welding process of single-sided welding and double-sided molding, the steps are:

[0025] (1) Make a Y-shaped bevel at the weld, with a bevel angle of 55° to 65°; clean the rust and oil stains on the surface of the bevel and the surrounding area within 20mm, either by mechanical processing or by using organic solvents The method of immersion, etc., until the groove exposes the metal surface.

[0026] (2) Place the workpiece obliquely, with the weld seam facing upwards, and the arc-starting end of welding is higher than the arc-ending end.

[0027] The method of determining the tilt angle is:

[0028] Assuming that the inclination angle of the weld relative to the horizontal plane is α, the plate thickness of the workpiece is x, the gap at the groove is y, y≤5mm, and the blunt edge height of the Y-shaped groove is z,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com