A ring forging yoke structure of a generator motor

A technology for generator motors and annular forgings, which is applied to the shape/style/structure of the magnetic circuit and the static parts of the magnetic circuit, etc., can solve the problems of long manufacturing cycle, low material utilization rate, and complicated manufacturing process of steel plate stacked yoke, etc. Achieve the effect of reducing production cycle, reducing unsafe hidden dangers, reducing procurement weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

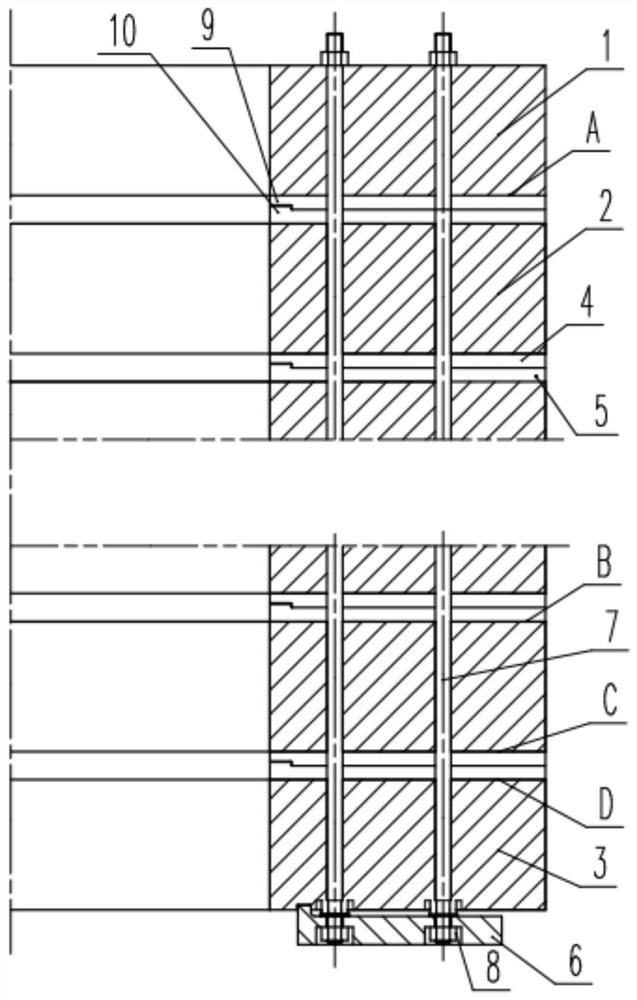

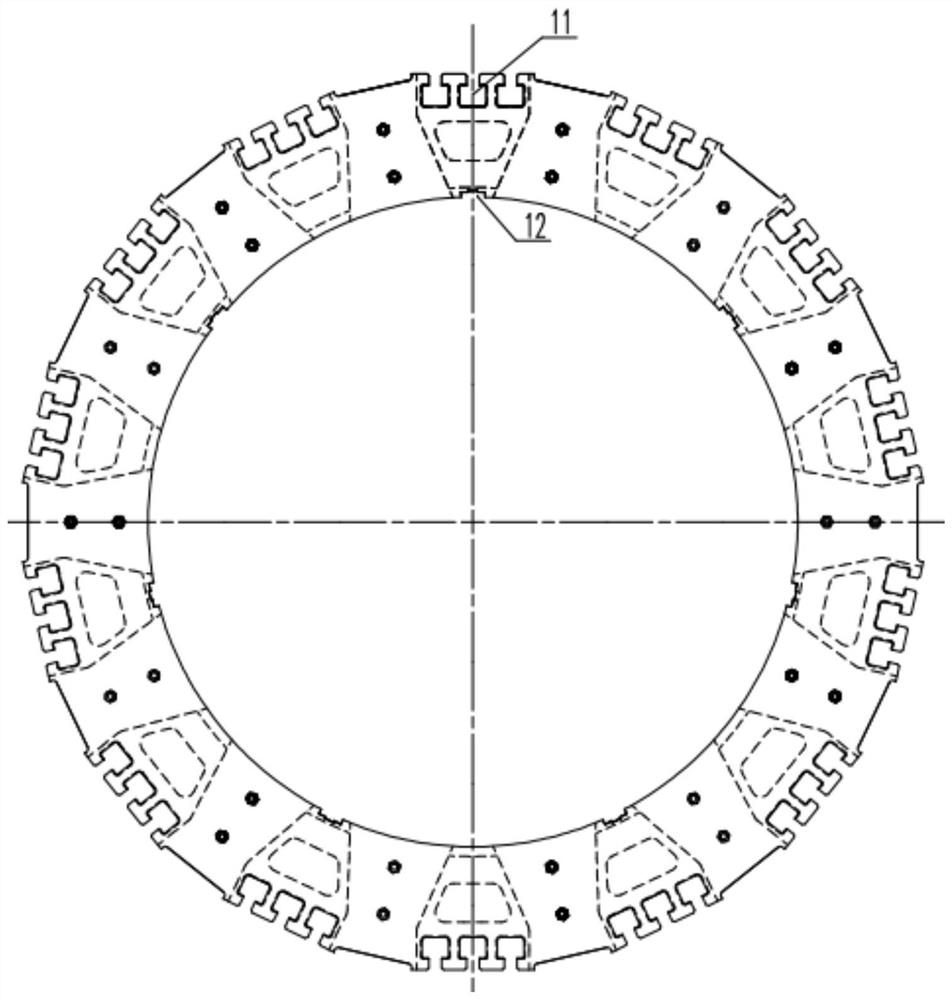

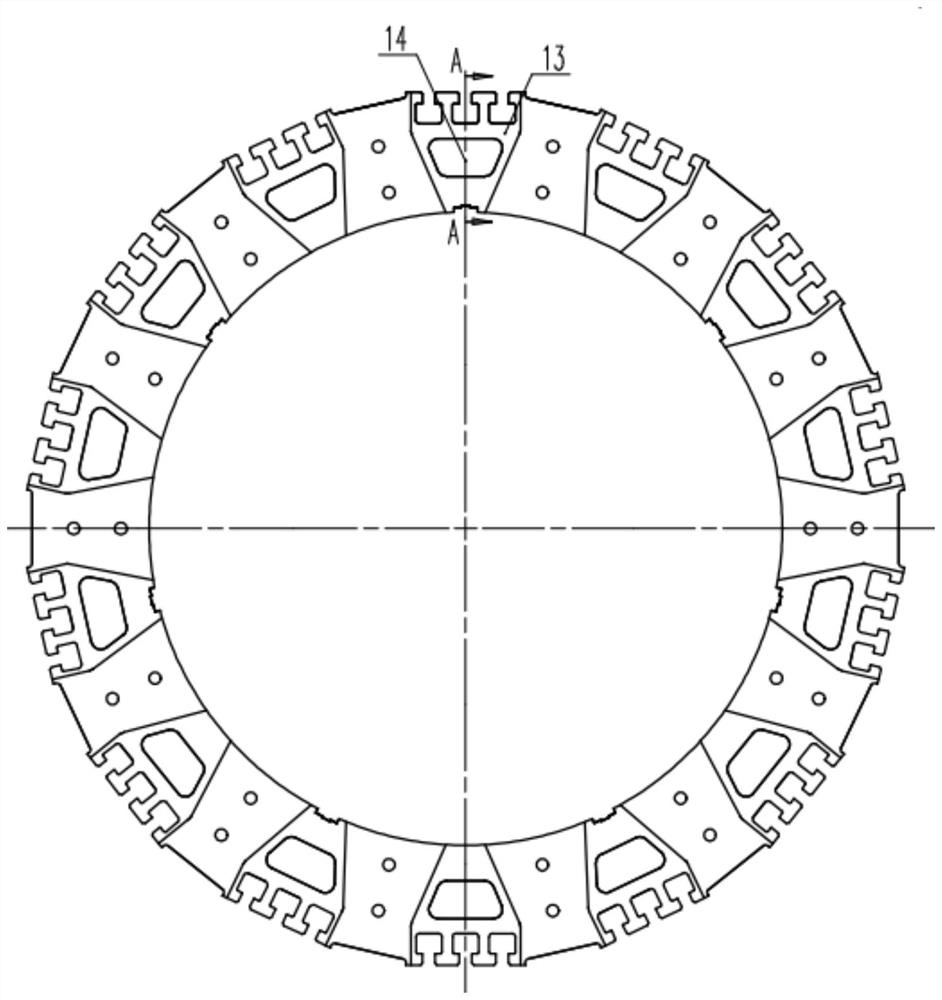

[0020] like figure 1 and figure 2 As shown, the ring forging yoke structure of the generator motor includes the first yoke 1, the middle yoke 2, the last yoke 3, the lower air deflector 4, the upper air deflector 5, the brake ring 6, and the yoke The tightening screw 7 and the nut 8 are composed; the lower plane A of the first yoke 1 is welded with the upper wind deflector 5 , and the upper plane B and the lower plane C of the middle yoke 2 are respectively welded with the upper wind deflector 5 and the lower wind deflector 4 , the upper plane D of the last yoke 3 is welded with the upper wind deflector 5, after welding, a concave stop 9 is processed in the inner diameter direction of the lower wind deflector 4 of each layer, and a raised stop 10 is processed in the inner diameter direction of the upper wind deflector 5 of each layer ; After each segment of the yoke is positioned through the concave notch 9 and the protruding notch 10 in the direction of the inner diameter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com