An insulating tube type bus structure design method

A design method and technology of busbar structure, applied in the direction of calculation, special data processing application, instrument, etc., can solve the problems of blind design of structure design, waste of resources, different structure design and production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

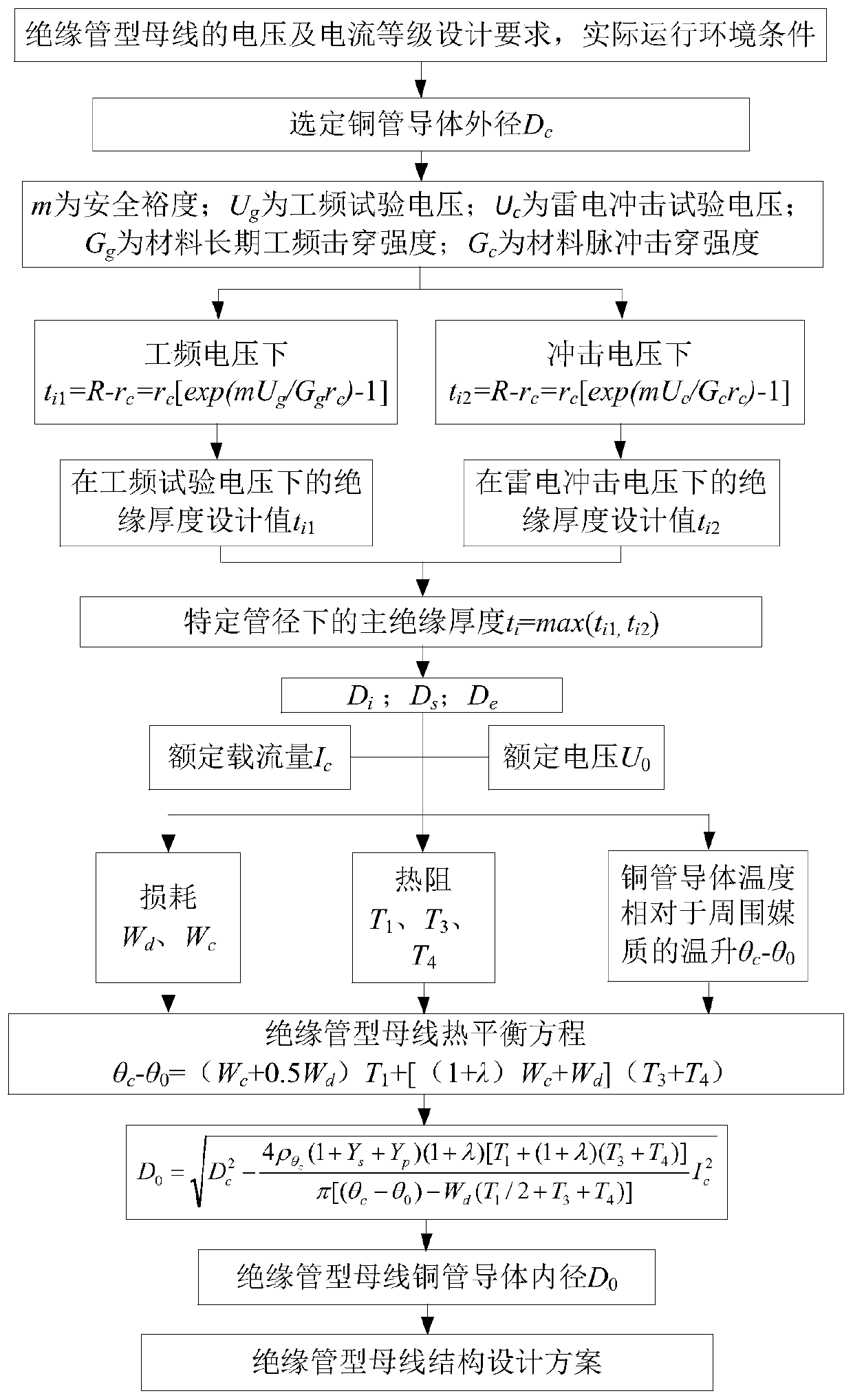

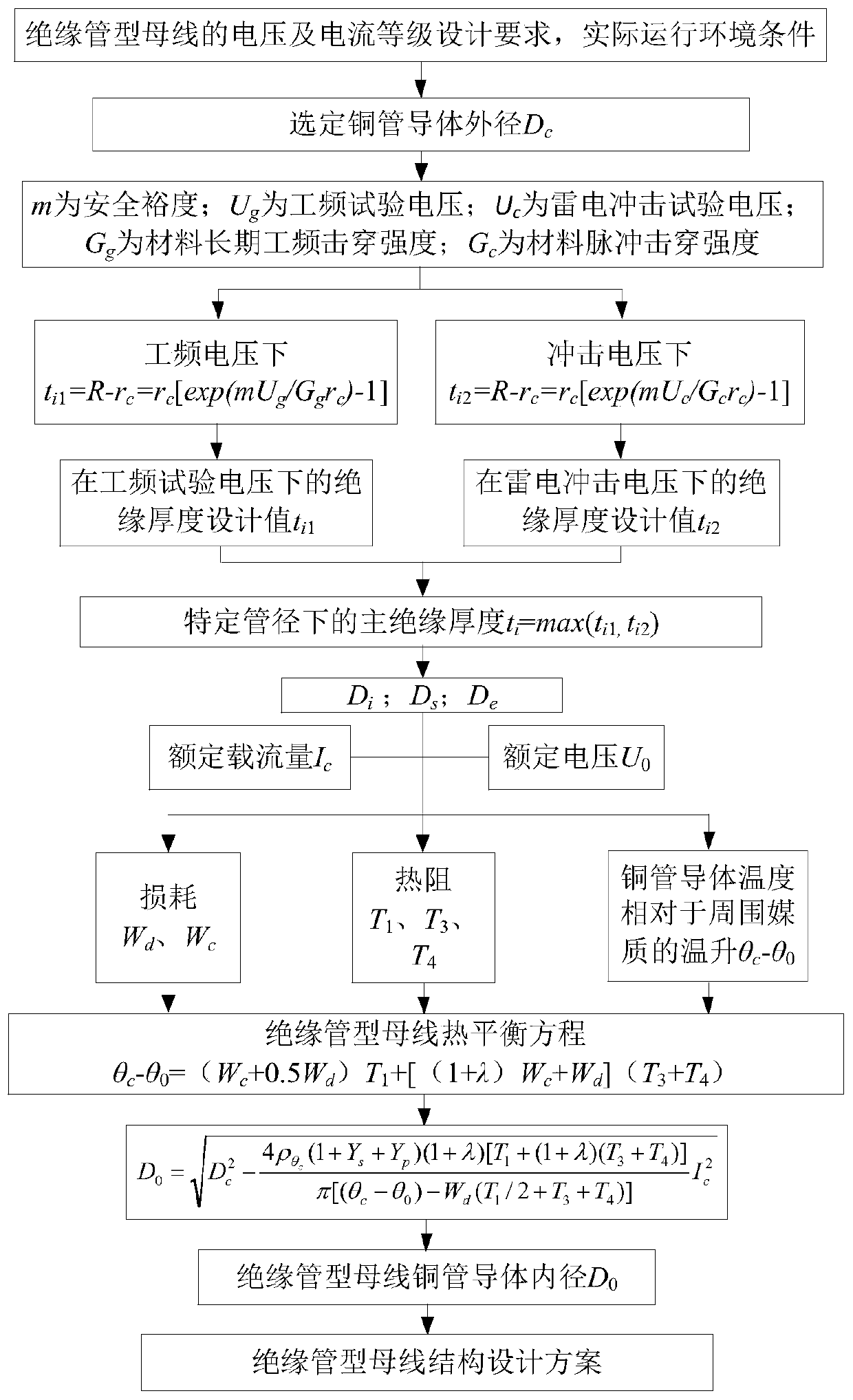

[0055] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

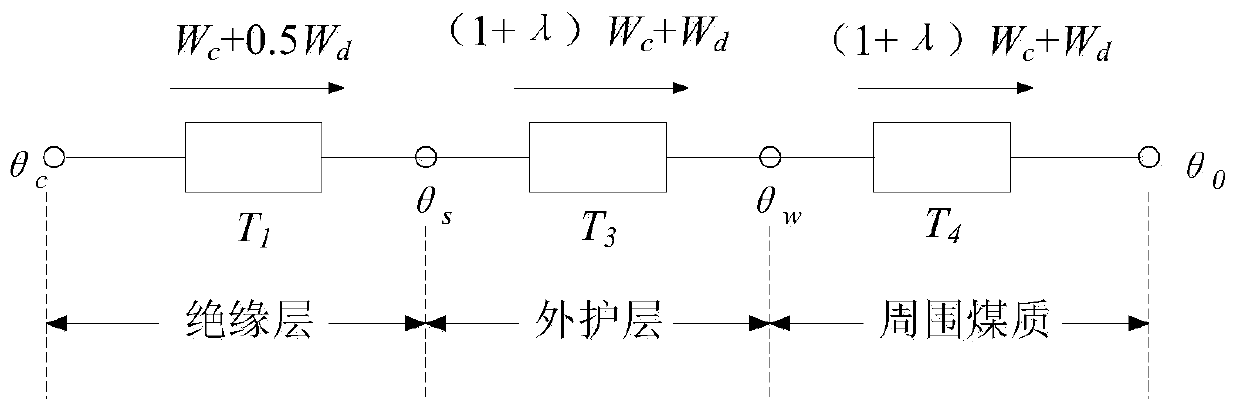

[0056] This embodiment takes 35kV / 4000A epoxy resin cast insulating tubular bus as an example, refer to Figure 1~2 , a structural design method for an insulating tubular busbar, which mainly involves: first, the structural design part of the insulating tubular busbar, that is, under the premise of known voltage and current level design requirements, design the cross-sectional size of the current-carrying conductor and the main insulating layer Thickness, that is, the diameter, wall thickness and thickness of the main insulation layer of the copper pipe conductor; the second is the structural calculation part of the insulating tubular bus, that is, the calculation of whether the insulating tubular bus structure meets the design requirements, that is, the structure of the insulating tubular bus Whether t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com