A Method for Debonding Evaluation of Honeycomb Sandwich Structures at High Temperature

A honeycomb interlayer and debonding technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems such as the non-existent debonding evaluation method of honeycomb sandwich structure, and achieve the effect of good evaluation results, clear evaluation process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

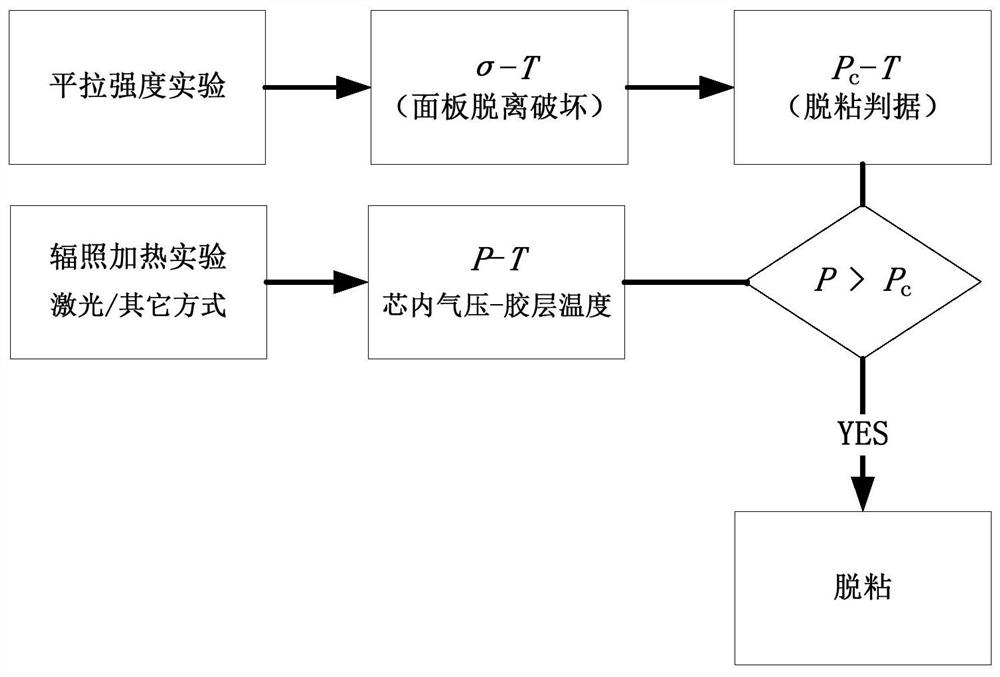

[0033] see figure 1 , a method for evaluating debonding of honeycomb sandwich structures at high temperatures, the main steps of which are:

[0034] Step 1) select the honeycomb sandwich structure sample; the honeycomb sandwich structure sample is selected in the honeycomb sandwich structure to be evaluated in the same process or the same factory batch;

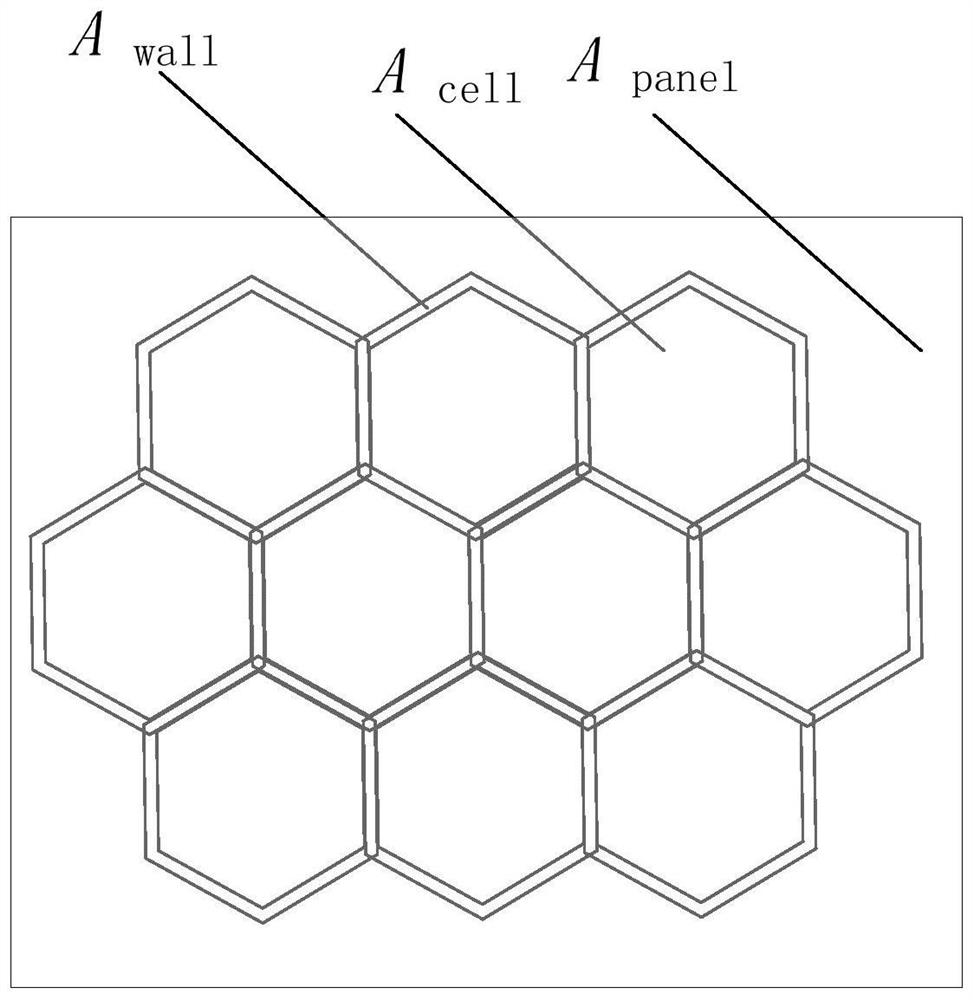

[0035] Step 2) Carry out a flat tensile strength test on the honeycomb sandwich structure sample to obtain the adhesive layer strength σ(T) between the panel and the honeycomb core of the honeycomb sandwich structure;

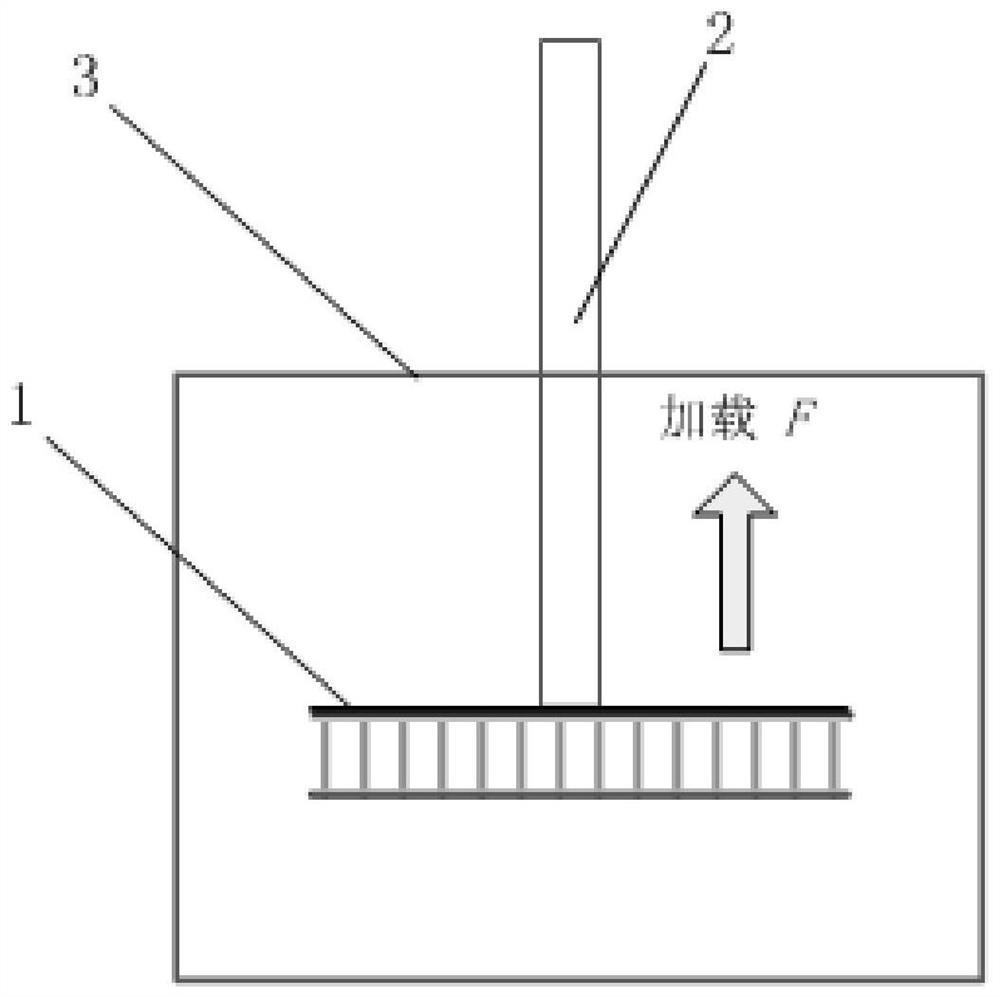

[0036] see figure 2 , set the temperature T of the heating furnace 3, and use the heating furnace 3 to heat the sample of the honeycomb sandwich structure to thermal equilibrium; pass the mechanical loading rod 2 through the high-temperature resistant adhesive layer 1 (one point to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com