Marine concrete impacting and grinding test device and test method thereof

A technology of marine concrete and test equipment, which is applied in the direction of testing wear resistance, etc., can solve the problems of complex marine concrete, difficulty in abrasion and damage, single consideration factors, etc., and achieve real marine environment, wide range of water flow speed, and few raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

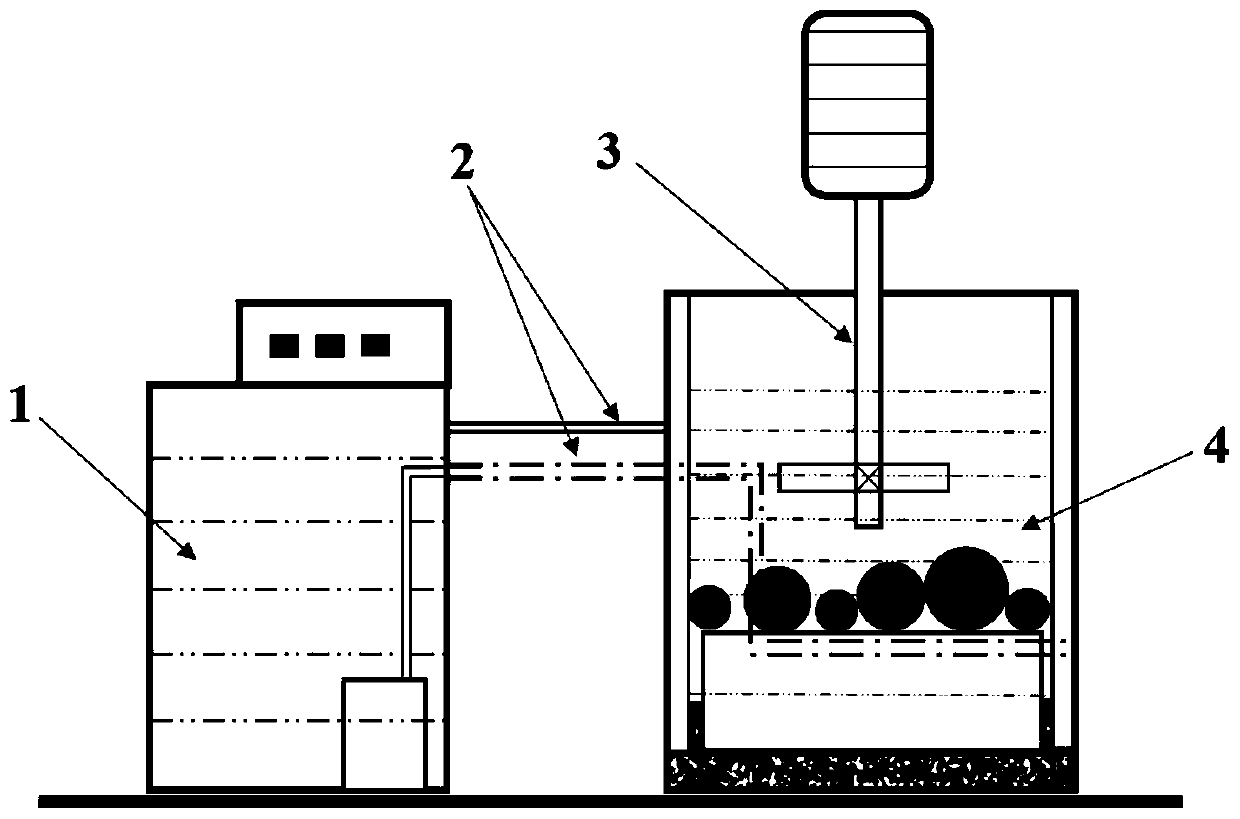

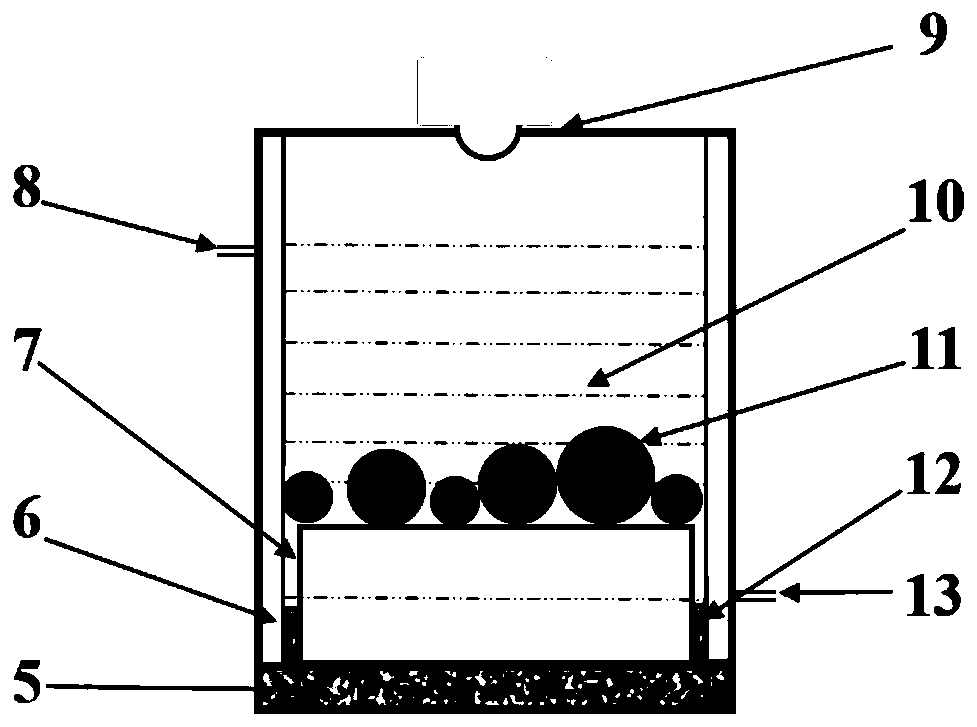

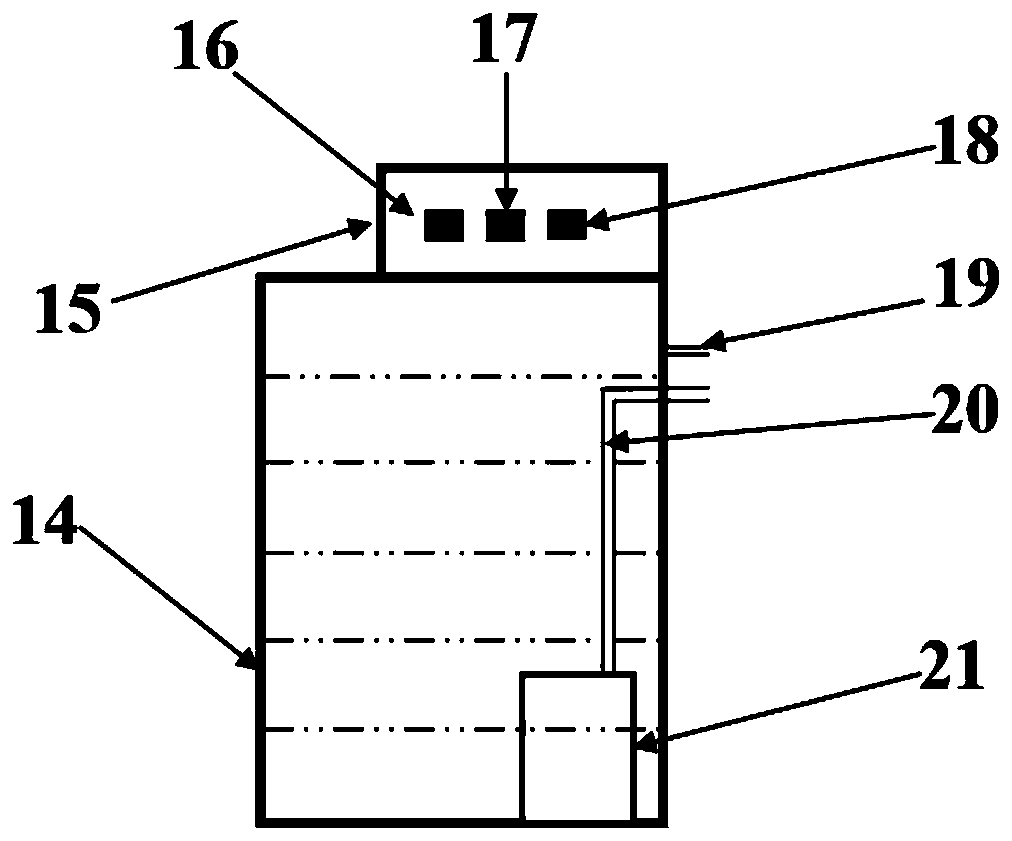

[0041] Such as figure 1 As shown, a test device for testing the abrasion resistance of marine concrete includes a test container 4 for containing simulated seawater and test pieces, a temperature control device (or a circulating water bath) for controlling the temperature of the test environment in the test container 4 temperature control device) 1, and a stirring device 3 for driving water flow and simulating sea wave erosion and a connecting pipe (silicone hose) 2 for connecting the test container and the temperature control device; the test piece 7 is located in the test container 4, and the test piece 7 is fixed on the test container 4 by the bottom fixing part 12. During use, the test container 4 is equipped with an artificial seawater solution 10 {artificial seawater solution is simulated seawater, and the test piece 7 and the grinding medium (steel ball) are immersed in the artificial seawater solution 10 Inside}, the upper surface of the test piece 7 is paved (placed) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com