Gun bore inner wall wiping machine

A gun bore and main engine technology, which is applied in the field of gun bore inner wall wiping machine, can solve the problems that affect the cleaning effect, can't clean the gun bore, and the inner diameter of small-caliber artillery is small, so as to improve the wiping efficiency and the degree of wiping automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

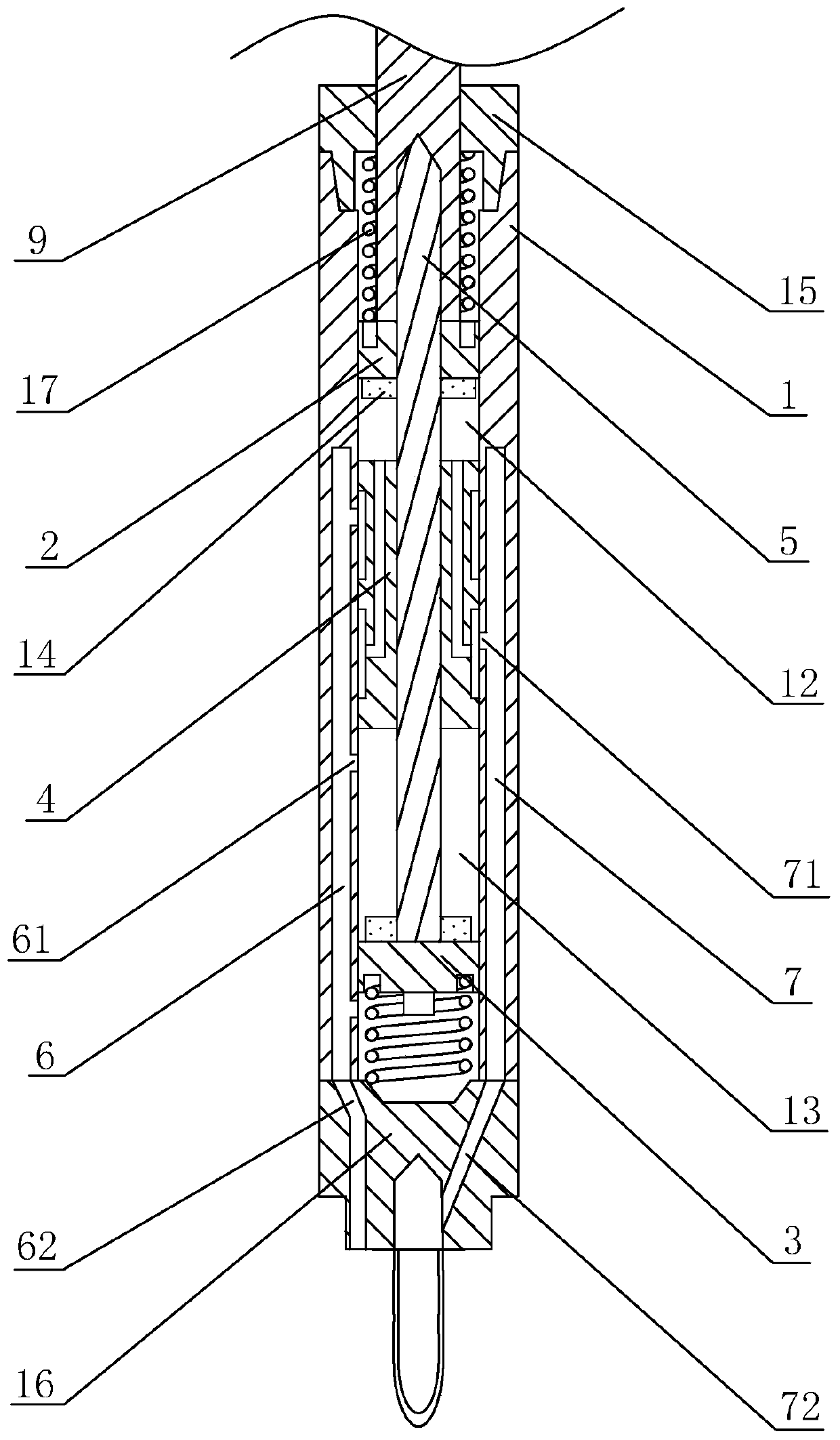

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

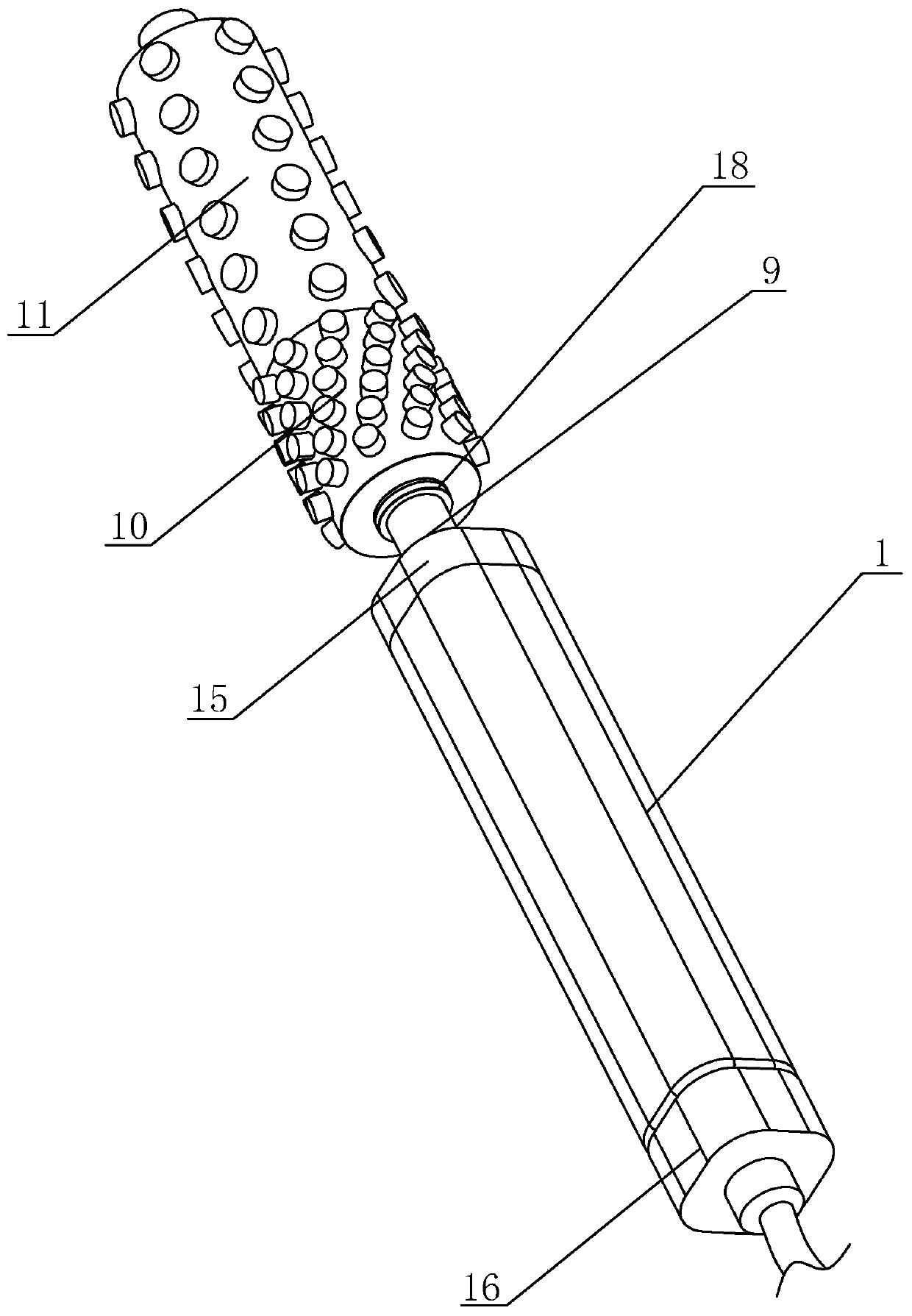

[0042] A gun bore inner wall wiping machine disclosed by the invention comprises a power propulsion part and an inner bore cleaning part.

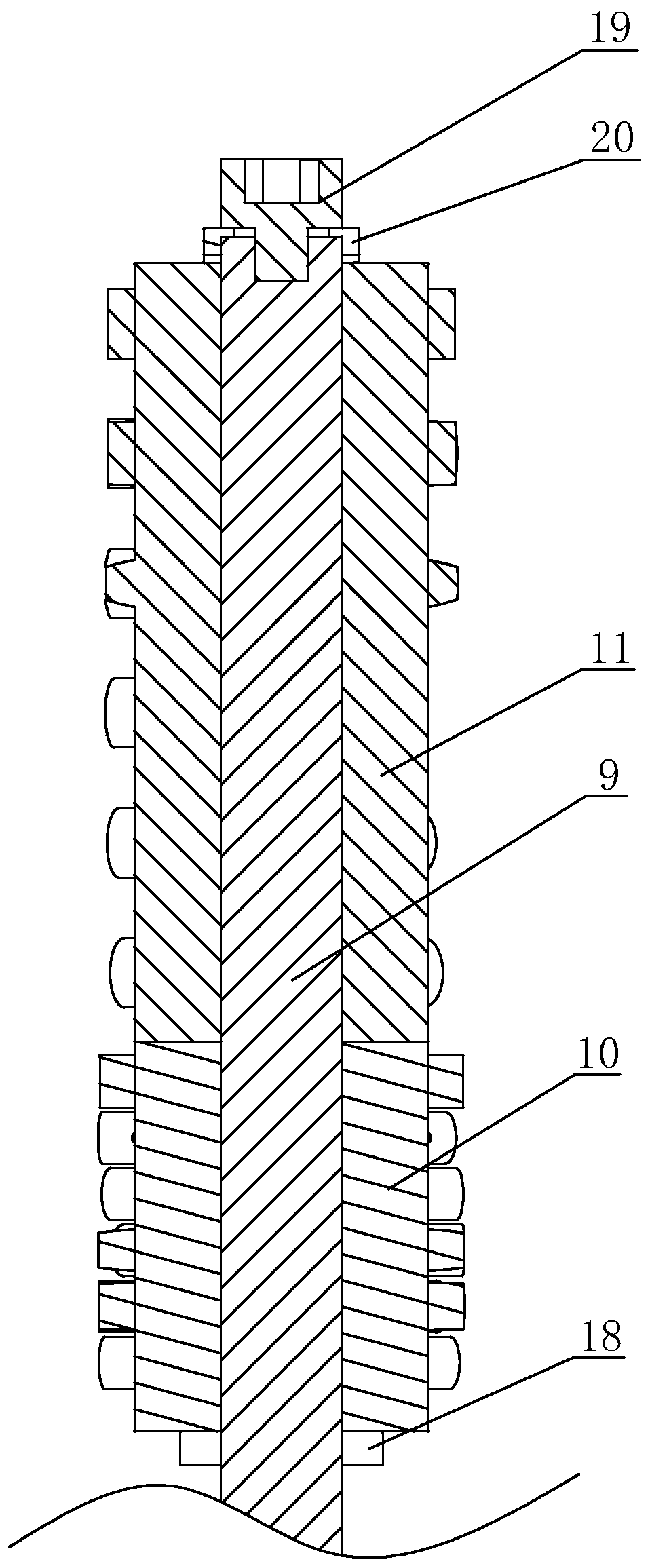

[0043] refer to figure 1 , the power propulsion part includes a main engine cylinder body 1, the main engine cylinder body 1 is arranged in a cuboid or cylindrical shape and its interior is hollow along its length direction, and the two ends of the main engine cylinder body 1 are respectively clamped with a front sleeve 15 and a rear sleeve. Set of 16. The replacement of the internal components of the main cylinder 1 can be realized through the detachable front cover 15 and the rear cover 16 .

[0044] refer to image 3 , the two ends inside the main engine cylinder body 1 are elastically slidable respectively along the length direction to set the top fixing seat 2 and the tail fixing seat 3, and a return spring 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com