Three-stage power transmission system of vertical circulating stereo garage

A technology of power transmission system and three-dimensional garage is applied in the field of three-stage transmission system, which can solve the problems of contact surface damage and failure, and achieve the effect of high degree of bonding, noise reduction, and prevention of transmission failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

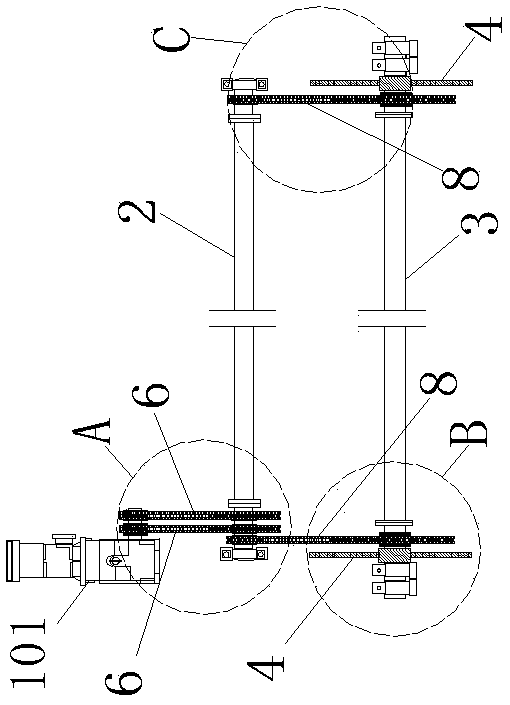

[0042] Example 1. Such as Figure 1-4 , as shown in 7-8, a three-stage power transmission system for a vertical circulation three-dimensional garage, is characterized in that: the transmission system includes a main motor 101, a reduction motor 1, a secondary transmission shaft 2, a tertiary transmission shaft 3, two The first-stage transmission shaft 2 is arranged between the geared motor 1 and the third-stage transmission shaft 3 and is parallel to the power output shaft 11 and the third-stage transmission shaft 3 of the geared motor 1; between the geared motor 1 and the second-stage transmission shaft 2, the second-stage transmission The shaft 2 and the third-stage transmission shaft 3 are all connected by chain transmission; the third-stage transmission shaft 3 is provided with a circulating chain drive wheel 4; the main motor 101 is connected with the reduction motor 1 .

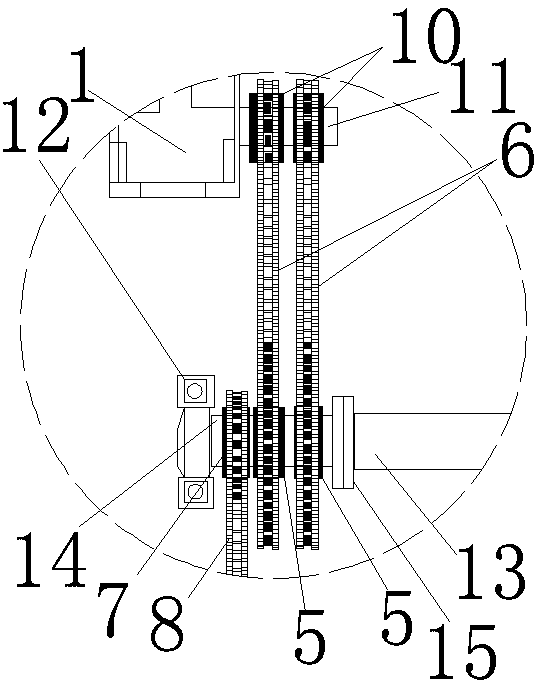

[0043] The transmission system includes a reduction motor 1, two primary transmission sprockets 5, ...

Embodiment 2

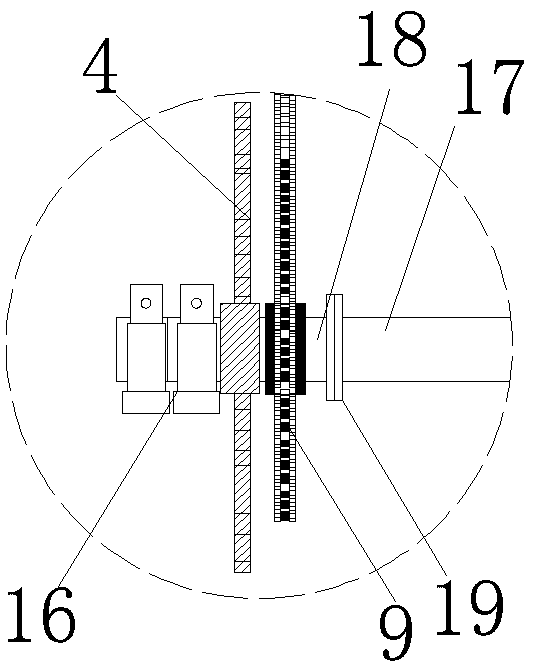

[0059] Example 2. Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the transmission system includes a reduction motor 1, a primary transmission sprocket 5, a primary circular transmission chain 6, a secondary transmission shaft 2, and two secondary transmission chains Wheel 7, two secondary endless drive chains 8, tertiary drive shaft 3, two tertiary drive sprockets 9, two loop chain drive wheels 4.

[0060] The secondary transmission shaft 2 , the tertiary transmission shaft 3 , and the PTO shaft 11 of the geared motor 1 are parallel to each other, and the secondary transmission shaft 2 is arranged between the tertiary transmission shaft 3 and the PTO shaft 11 of the geared motor 1 .

[0061] The power output shaft 11 of the reduction motor 1 is provided with a power output wheel 10; the primary transmission sprocket 5 is arranged on the secondary transmission shaft 2 and is in the same plane as the power output wheel 10; the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com