Cast-in-place pile casing capable of reducing lifting resistance

A cast-in-place pile and casing technology, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low reuse rate of casing, unfavorable side wall soil stability, affecting the quality of foundation construction, etc. The hole wall is stable, the structure is simple, and the effect of reducing the mechanical embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

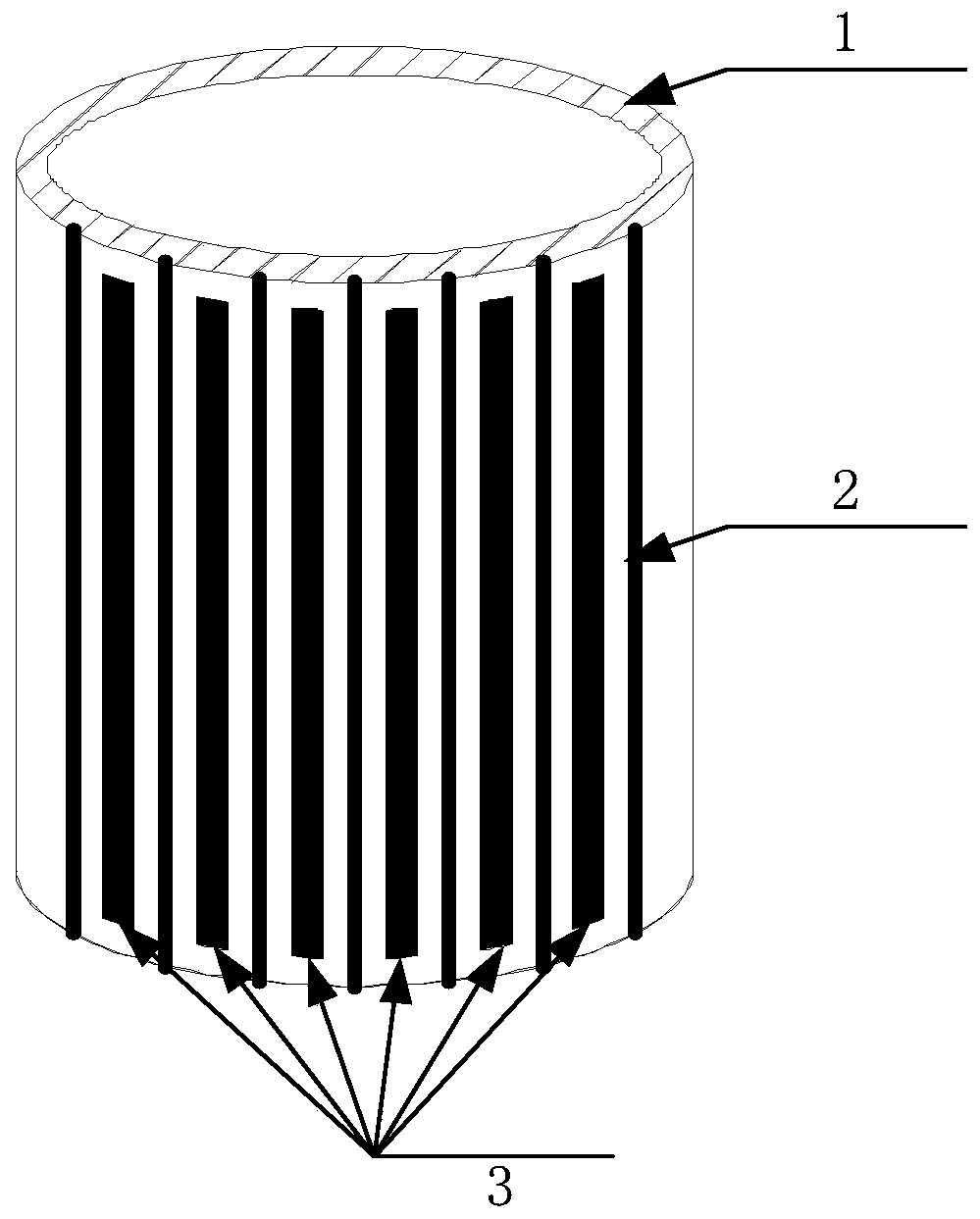

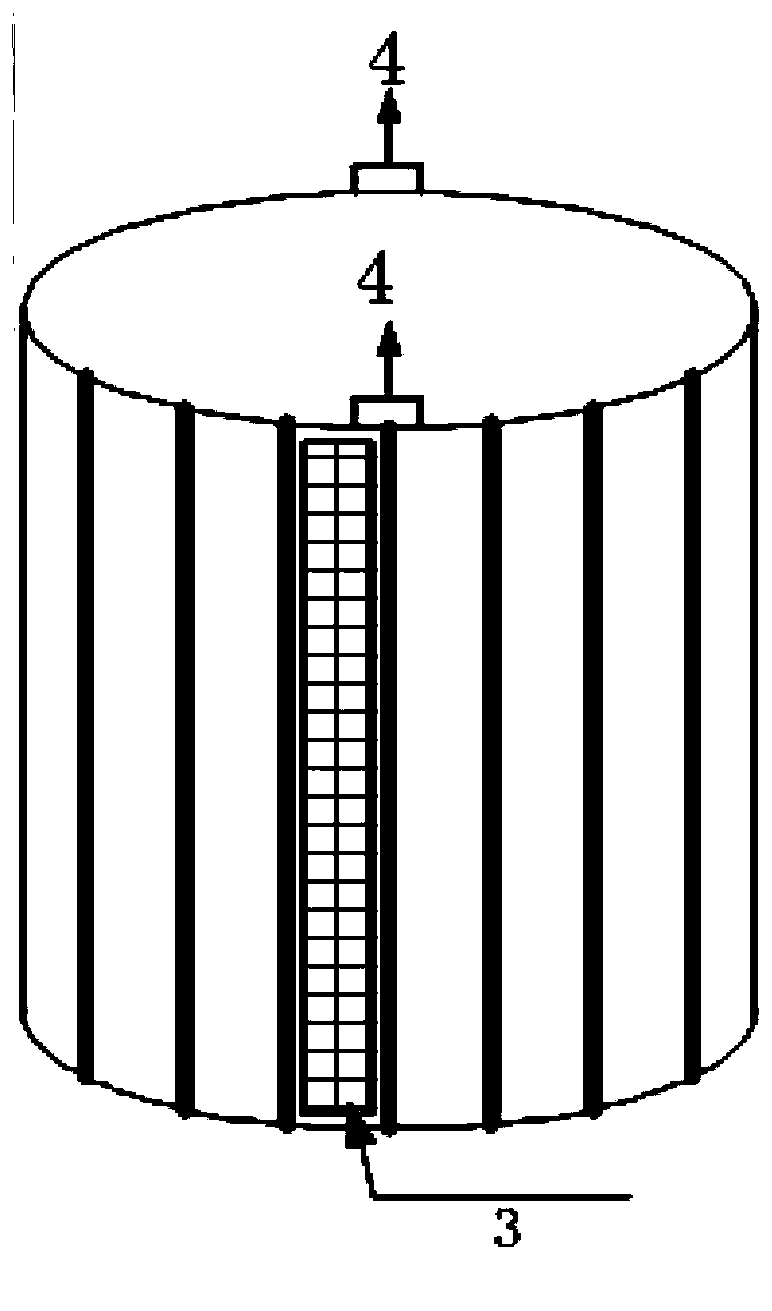

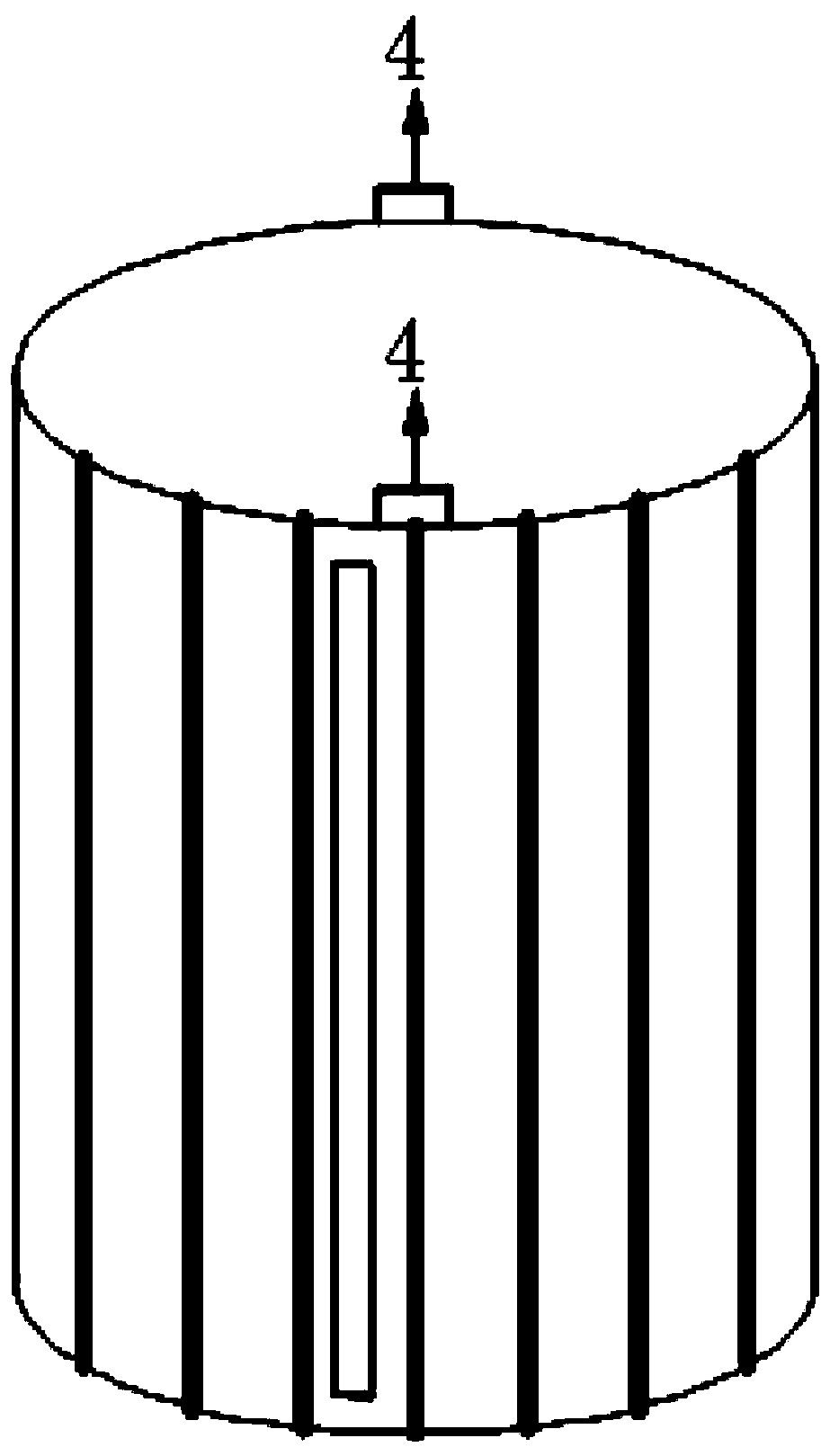

[0038] A cast-in-situ pile casing with reduced lifting resistance, the casing includes a steel cylinder 1, lifting lugs, spacers 2 attached to the steel cylinder and expansion bags 3 between the spacers. The steel cylinder is made of a material comprising the following components by mass percentage: Si: 0.5%, Fe: 0.5%, Cu: 4.1%, Mn: 0.7%, Mg: 1.5%, Ni: 0.1% , Zn: 0.3%, Ti: 0.15%, the balance is Al, and the cross section is circular. The lifting lugs are symmetrically welded on the steel cylinder with the diameter of the steel cylinder as the standard. The hanging lug is made of materials including the following components by mass percentage: steel with a carbon content of 0.12%. The spacers are evenly distributed on the outer wall of the steel cylinder based on the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com