Prefabricated coil polyurethane runway surface layer and construction process thereof

A construction technology, polyurethane technology, applied in roads, pavements, roads, etc., can solve the problems of low elastic absorption rate, low tensile strength, and uneven unevenness, and achieve improved tensile strength, improved overall performance, high elastic performance and The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

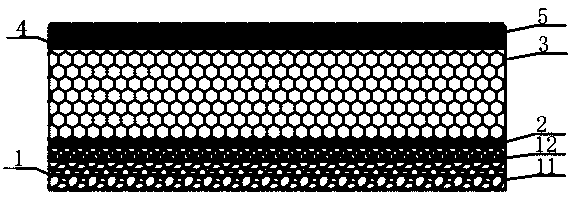

[0035] according to Figure 1-4 A prefabricated roll material polyurethane runway surface layer as shown comprises a laying base 1, and a prefabricated laying roll 3 is arranged on the top of the laying base 1, and a prefabricated laying roll 3 is arranged between the laying base 1 Polyurethane adhesive layer 2, the top of the prefabricated laying coil 3 is provided with a polyurethane reinforcement layer 4, and the top of the polyurethane reinforcement layer 4 is provided with a spray surface layer 5;

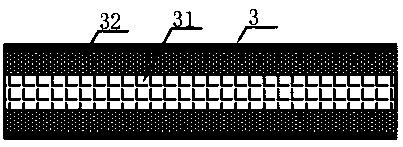

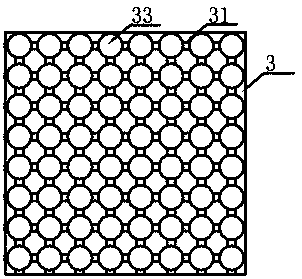

[0036] The prefabricated laying roll 3 includes an elastic support layer 31 and a foamed polyurethane layer 32, the elastic support layer 31 is arranged between two layers of foamed polyurethane layers 32, and the outer surface of the foamed polyurethane layer 32 is set as a horizontal plane ;

[0037] The laying base 1 includes a rough asphalt layer 11 and a fine asphalt layer 12, the rough asphalt layer 11 is arranged on the top of the fine asphalt layer 12, and the upper s...

Embodiment 2

[0054] according to Figure 1-4 A prefabricated roll material polyurethane runway surface layer as shown comprises a laying base 1, and a prefabricated laying roll 3 is arranged on the top of the laying base 1, and a prefabricated laying roll 3 is arranged between the laying base 1 Polyurethane adhesive layer 2, the top of the prefabricated laying coil 3 is provided with a polyurethane reinforcement layer 4, and the top of the polyurethane reinforcement layer 4 is provided with a spray surface layer 5;

[0055] The prefabricated laying roll 3 includes an elastic support layer 31 and a foamed polyurethane layer 32, the elastic support layer 31 is arranged between two layers of foamed polyurethane layers 32, and the outer surface of the foamed polyurethane layer 32 is set as a horizontal plane ;

[0056] The laying base 1 includes a rough asphalt layer 11 and a fine asphalt layer 12, the rough asphalt layer 11 is arranged on the top of the fine asphalt layer 12, and the upper s...

Embodiment 3

[0073] according to Figure 1-4 A prefabricated roll material polyurethane runway surface layer as shown comprises a laying base 1, and a prefabricated laying roll 3 is arranged on the top of the laying base 1, and a prefabricated laying roll 3 is arranged between the laying base 1 Polyurethane adhesive layer 2, the top of the prefabricated laying coil 3 is provided with a polyurethane reinforcement layer 4, and the top of the polyurethane reinforcement layer 4 is provided with a spray surface layer 5;

[0074] The prefabricated laying roll 3 includes an elastic support layer 31 and a foamed polyurethane layer 32, the elastic support layer 31 is arranged between two layers of foamed polyurethane layers 32, and the outer surface of the foamed polyurethane layer 32 is set as a horizontal plane ;

[0075] The laying base 1 includes a rough asphalt layer 11 and a fine asphalt layer 12, the rough asphalt layer 11 is arranged on the top of the fine asphalt layer 12, and the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com