Cross-linked starch microsphere preparation method

A technology of cross-linked starch and microspheres, which is applied in the field of material chemistry, can solve the problems that the application of inverse emulsion polymerization has not been widely concerned, and there are few research reports, so as to achieve uniform particle size distribution, improve adsorption capacity, and improve adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

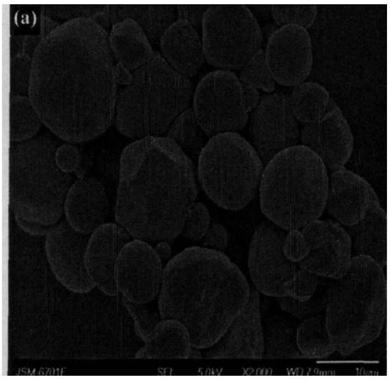

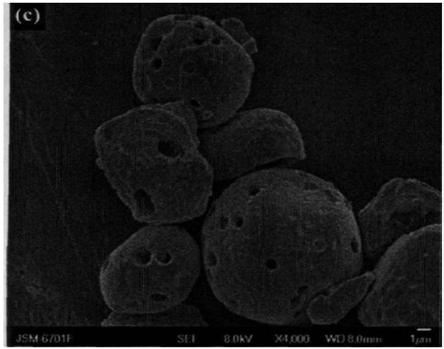

[0029] A preparation method of cross-linked starch microspheres, the steps are as follows:

[0030] (1) Add 100 parts of raw corn starch and a pre-configured buffer solution (pH = 5.5) to a 100mL round bottom flask, place the round bottom flask on a magnetic stirrer for stirring, and control the temperature of the system through a water bath is 50°C. Then, 0.2857 parts of glucoamylase and 1.7143 parts of α-amylase were added thereto, and reacted for 12 hours to obtain the product microporous starch. Subsequently, the Buchner funnel was used for suction filtration, and then the filter cake was washed successively with distilled water, a Ph=10 sodium hydroxide solution, and distilled water, and the filter cake was air-dried at room temperature after draining to obtain the product.

[0031] (2) Add 6 parts of sodium hydroxide, 2 parts of sodium chloride and 667 parts of distilled water to a 100 mL round bottom flask, and stir it with a magnetic stirrer to dissolve it. The devic...

Embodiment 2

[0037] A preparation method of cross-linked starch microspheres, the steps are as follows:

[0038] (1) Add 100 parts of raw corn starch and a pre-configured buffer solution (pH = 5.5) to a 100mL round bottom flask, place the round bottom flask on a magnetic stirrer for stirring, and control the temperature of the system through a water bath is 50°C. Then add 0.66 parts of glucoamylase and 1.34 parts of α-amylase to it, and react for 10 hours to obtain the product microporous starch. Subsequently, the Buchner funnel was used for suction filtration, and then the filter cake was washed successively with distilled water, a Ph=10 sodium hydroxide solution, and distilled water, and the filter cake was air-dried at room temperature after draining to obtain the product.

[0039] (2) Add 6 parts of sodium hydroxide, 2 parts of sodium chloride and 667 parts of distilled water to a 100 mL round bottom flask, and stir it with a magnetic stirrer to dissolve it. The device was placed in ...

Embodiment 3

[0043] A preparation method of cross-linked starch microspheres, the steps are as follows:

[0044] (1) Add 80 parts of raw corn starch and a pre-configured buffer solution (pH = 5.5) to a 100mL round bottom flask, place the round bottom flask on a magnetic stirrer for stirring, and control the temperature of the system through a water bath is 50°C. Then 0.2286 parts of glucoamylase and 1.3714 parts of α-amylase were added thereto, and reacted for 12 hours to obtain the product microporous starch. Subsequently, the Buchner funnel was used for suction filtration, and then the filter cake was washed successively with distilled water, a Ph=10 sodium hydroxide solution, and distilled water, and the filter cake was air-dried at room temperature after draining to obtain the product.

[0045] (2) Add 3 parts of sodium hydroxide, 1 part of sodium chloride and 533 parts of distilled water to a 100 mL round bottom flask, and stir it with a magnetic stirrer to dissolve it. The device w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com