Environmentally friendly disposal methods of food waste

An environmental protection treatment and waste technology, applied in the field of environmental protection treatment of food waste, can solve the problems that plague production enterprises and environmental protection departments, low thermal efficiency of food waste, low efficiency of resource utilization, etc., and achieve energy resource conservation and good promotion Application prospects, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] An environmentally friendly treatment method for food waste, comprising the steps of:

[0057] Ⅰ. Pretreatment: According to the mass ratio of 100:20, mix food waste and rice husk, put it under the conditions of 135°C and 0.3MPa working pressure for 20 minutes, crush it to 40 mesh, and finally put it in Dry to 10wt% at 50°C to obtain a pretreated mixture;

[0058] Ⅱ. Fermentation: Add fermenting agent to the above-mentioned pretreated mixture, the mass ratio of the pretreated mixture and fermenting agent is 100:10, stir at 70°C at a speed of 24r / min for 3h, then Placed under the condition of 50°C for aerobic fermentation for 10 days to obtain a fermentation product;

[0059] Ⅲ. Drying: Dry the above-mentioned fermentation product at 70°C and an absolute pressure of 0.04MPa for 2 hours to obtain an organic compound fertilizer.

[0060] The food waste is obtained by mixing pomelo pomace residue, potato peel, and citrus residue in a mass ratio of 3:1:1, crushing through ...

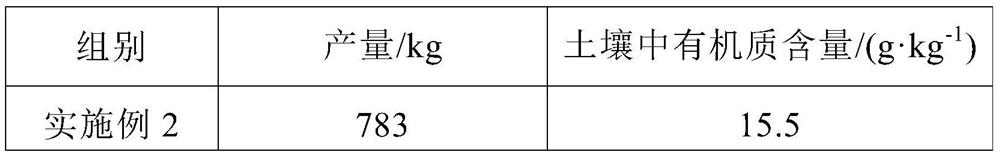

Embodiment 2

[0064] An environmentally friendly treatment method for food waste, comprising the steps of:

[0065] Ⅰ. Pretreatment: According to the mass ratio of 100:20, mix food waste and rice husk, put it under the conditions of 135°C and 0.3MPa working pressure for 20 minutes, crush it to 40 mesh, and finally put it in Dry to 10wt% at 50°C to obtain a pretreated mixture;

[0066] Ⅱ. Fermentation: Add fermenting agent, alkali-treated attapulgite and sepiolite to the above-mentioned pretreated mixture, and the pretreated mixture, fermenting agent, alkali-treated attapulgite and sepiolite The mass ratio is 100:10:5:5, stirred at 70°C at a speed of 24r / min for 3h, and then placed at 50°C for aerobic fermentation for 10 days to obtain a fermentation product;

[0067] Ⅲ. Drying: Dry the above-mentioned fermentation product at 70°C and an absolute pressure of 0.04MPa for 2 hours to obtain an organic compound fertilizer.

[0068] The food waste is obtained by mixing pomelo pomace residue, po...

Embodiment 3

[0072] An environmentally friendly treatment method for food waste, comprising the steps of:

[0073] Ⅰ. Pretreatment: According to the mass ratio of 100:20, mix food waste and rice husk, put it under the conditions of 135°C and working pressure of 0.3MPa, sterilize under high temperature and high pressure for 20 minutes, and crush it to 40 mesh to obtain sterilization food waste; the above-mentioned sterilized food waste was dried at 50°C to a moisture content of 16wt%, then extruded at 170°C for 20s, cooled to 25°C, and finally dried at 50°C to 10wt% , to obtain the pretreated mixture;

[0074] Ⅱ. Fermentation: Add fermenting agent, alkali-treated attapulgite and sepiolite to the above-mentioned pretreated mixture, and the pretreated mixture, fermenting agent, alkali-treated attapulgite and sepiolite The mass ratio is 100:10:5:5, stirred at 70°C at a speed of 24r / min for 3h, and then placed at 50°C for aerobic fermentation for 10 days to obtain a fermentation product;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com