Mechanical double-overrunning clutch adaptive automatic transmission external motor drive axle

A technology that surpasses clutch and automatic transmission, and is applied to mechanical equipment, power devices, transmission devices, etc., to achieve the effects of reducing manufacturing costs, running smoothly, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

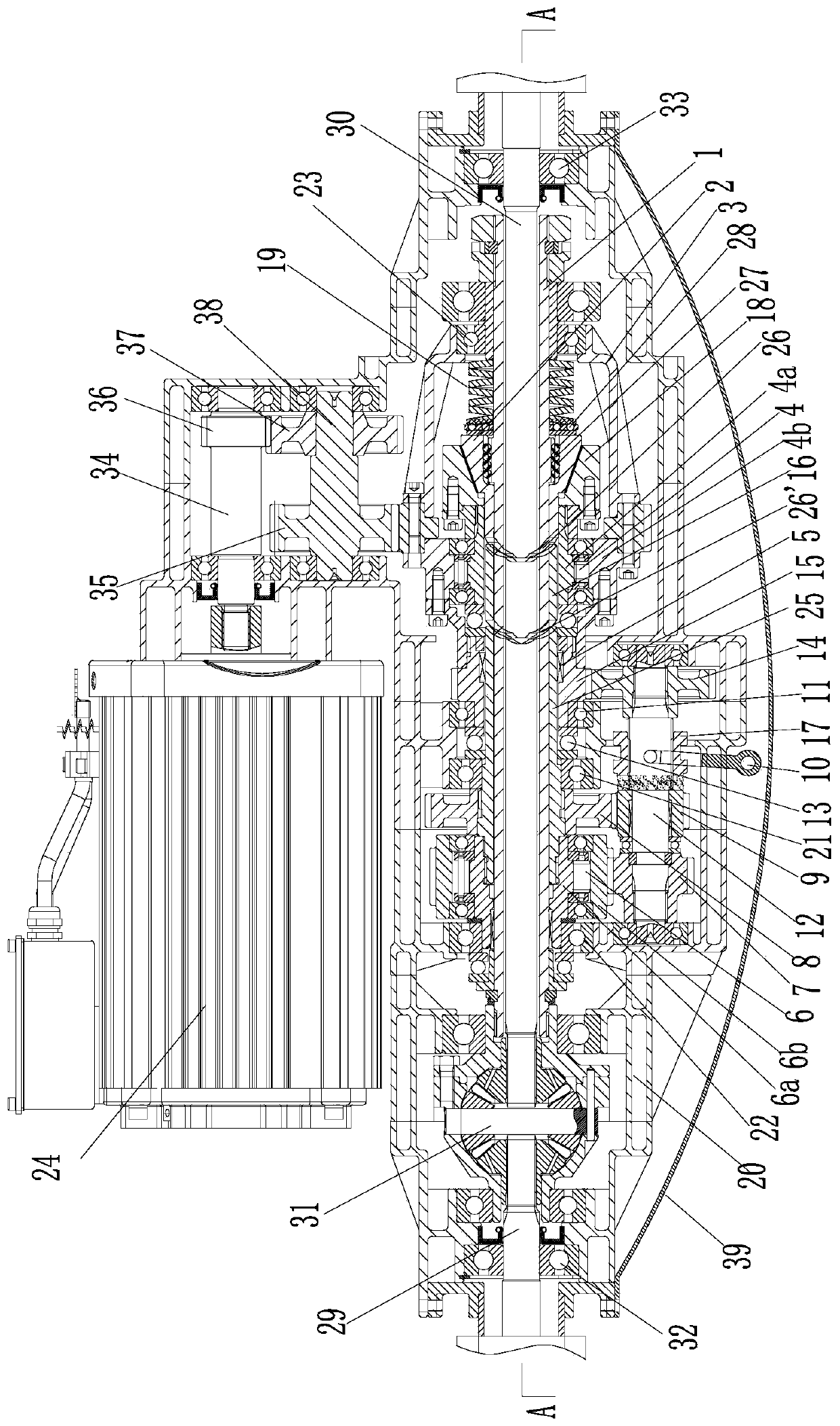

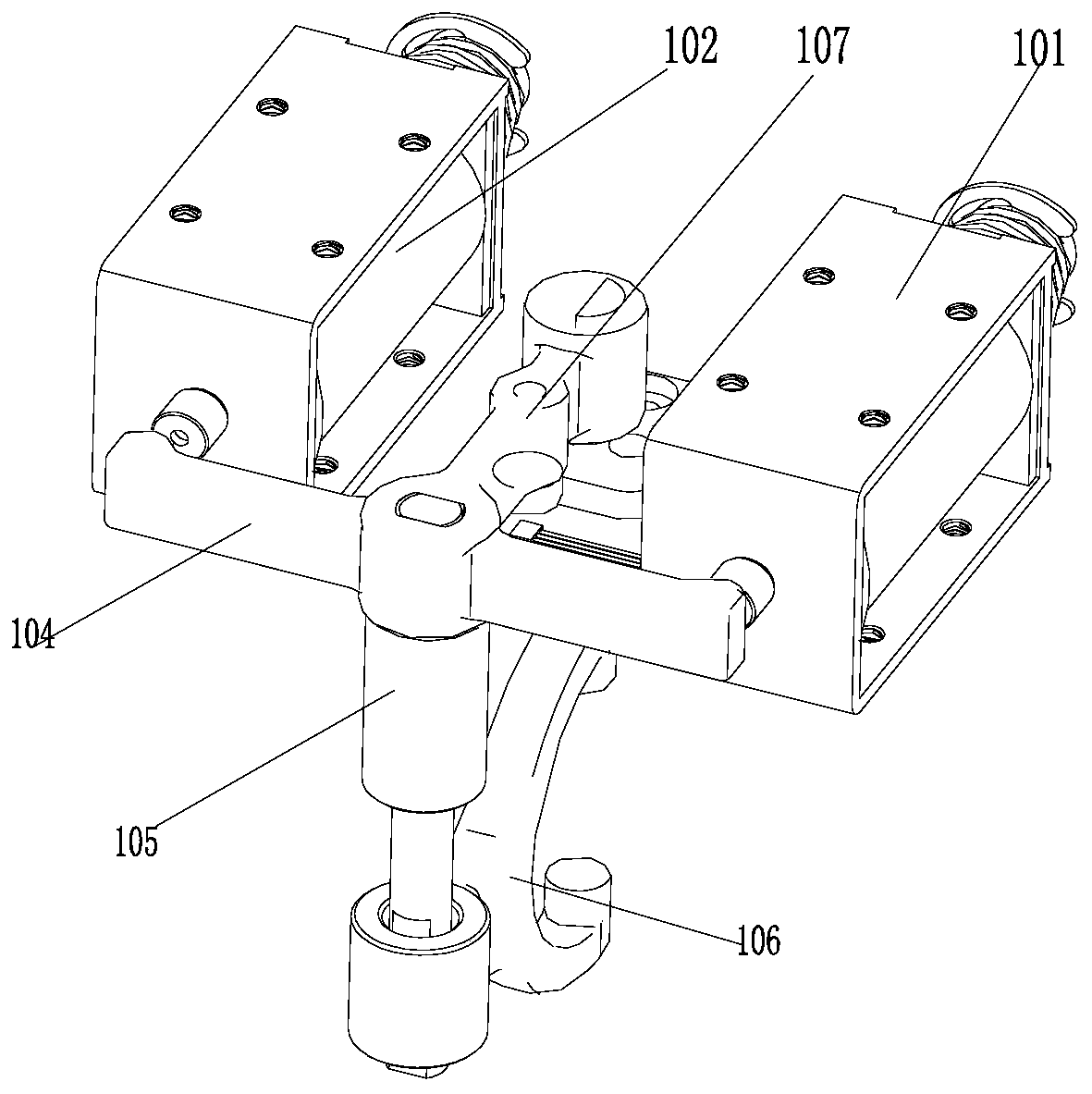

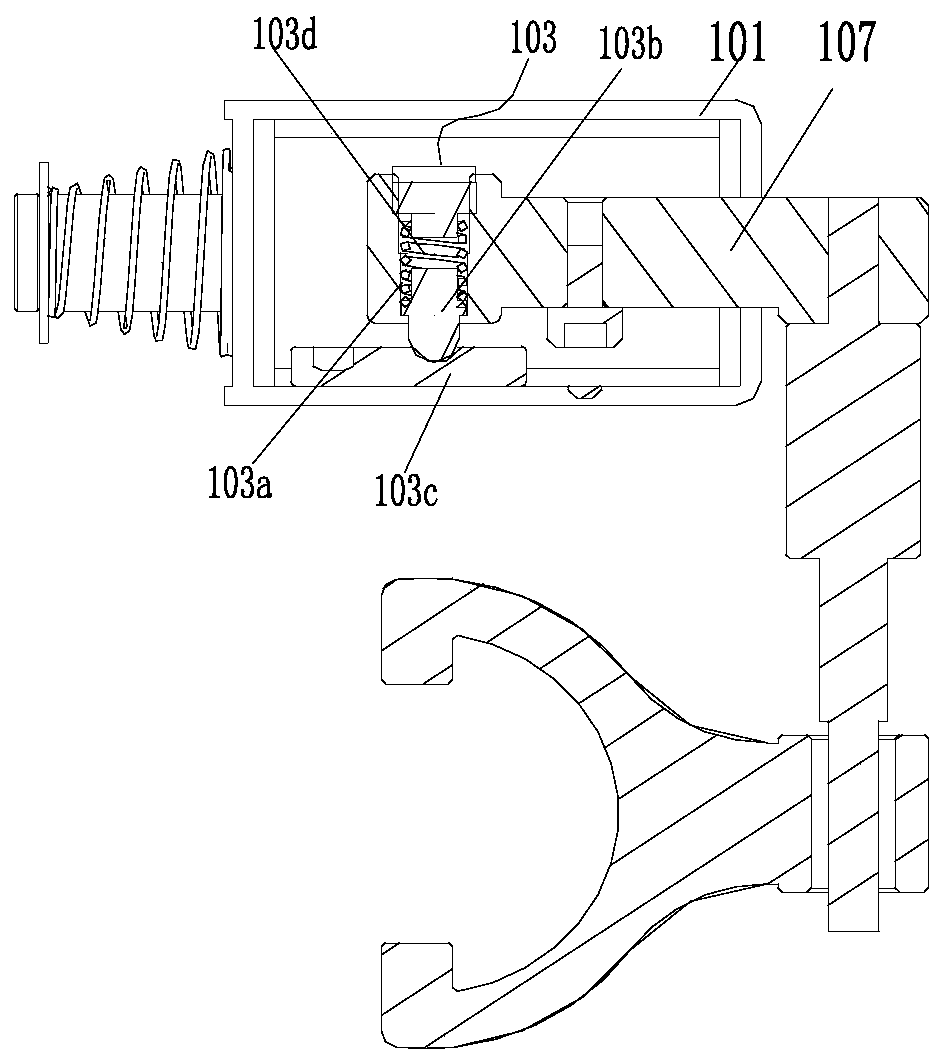

[0048] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 It is a schematic diagram of the electromagnetic shifting structure, image 3 Sectional view of electromagnetic shifting structure, Figure 5 for figure 1 A sectional view along A-A, as shown in the figure: the mechanical dual overrunning clutch adaptive automatic variable speed external motor drive axle of the present invention includes a drive motor, an axle housing 20, and a differential and a speed changer located in the axle housing. The transmission includes a hollow main shaft 1 and a transmission system on the hollow main shaft 1, and the transmission system includes a low gear transmission mechanism, a reverse gear transmission mechanism and an adaptive transmission assembly;

[0049] The adaptive transmission assembly includes driven friction parts, active friction parts and variable speed elastic elements;

[0050] The active friction part and the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com