Mineral processing method of protective scales for fine-grained crystalline graphite ore

A technology of crystalline graphite and beneficiation method, which is applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of high output, protection of scale particle size, and low degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

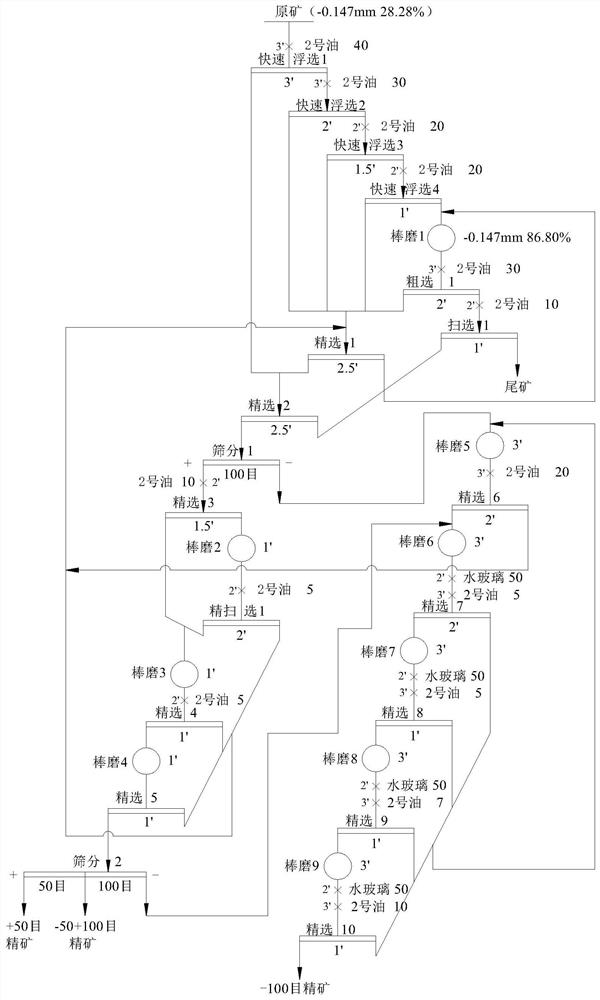

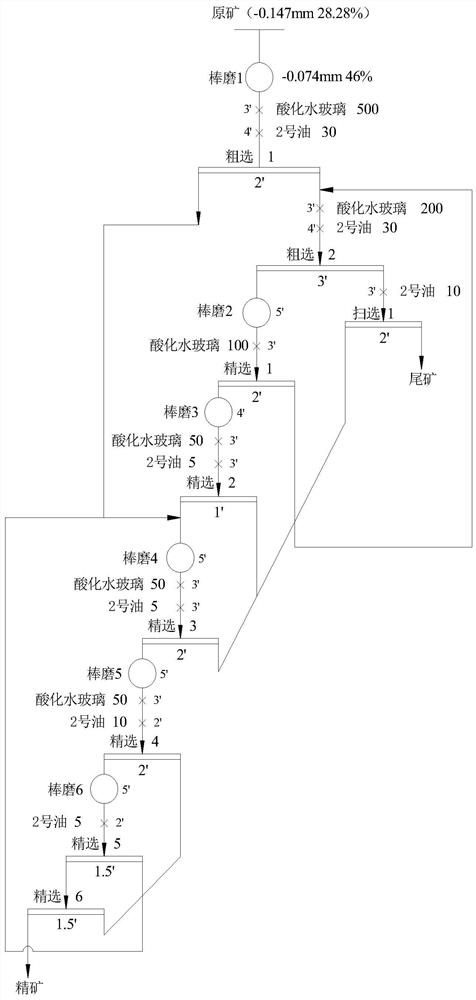

[0027] Such as figure 1 Shown, the beneficiation method of the protection scale that fine-grained crystalline graphite ore of the present invention is used may further comprise the steps:

[0028] 1. (Rough selection stage) Raw ore samples are prepared until the fineness is -0.147mm, accounting for 28.28%. Add No. 2 oil 40g / t and stir for 3 minutes, then enter into fast flotation 1, flotation for 3 minutes, and the obtained fast flotation 1 tailings slurry is then Add No. 2 oil 30g / t and stir for 3 minutes, then enter into rapid flotation 2, flotation for 2 minutes, and then add No. 2 oil 20g / t and stir for 2 minutes, then enter into rapid flotation 3, flotation 1.5 Minutes, the obtained rapid flotation 3 tailings slurry is added to No. 2 oil 20g / t and stirred for 2 minutes, then enters rapid flotation 4, flotation for 1 minute, the obtained rapid flotation 4 tailings slurry enters rod mill 1 for grinding, and the fineness -0.0147mm, accounting for 86.80%. After grinding, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com