Essence microcapsule capable of being used for heating nonflammable cigarette and preparation method of essence microcapsule

A flavor microcapsule and heat-not-burn technology, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve the problems of flavor loss and other problems, and achieve the effects of short production cycle, improved suction quality, improved permeability and fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

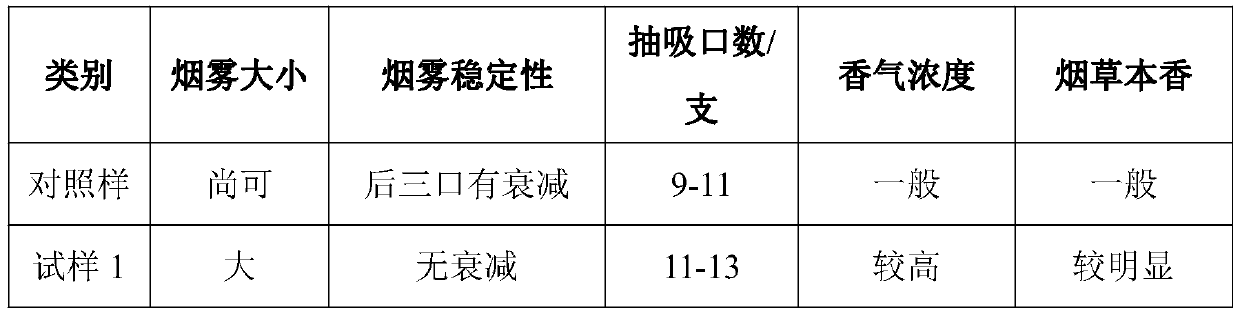

Embodiment 1

[0029] A method for preparing essence microcapsules applicable to heat-not-burn cigarettes, comprising the following steps:

[0030] (1) Weighing 0.3 g of methylcellulose and dissolving it in distilled water to prepare an aqueous solution of methylcellulose with a concentration of 0.5 wt %, and stirring for 60 minutes with a stirring speed of 200 rpm by a mechanical stirrer to make an emulsifier solution for subsequent use;

[0031] (2) Mix and stir the tobacco essence and glycerin according to the mass ratio of 1:10 to obtain the essence mixture completely, the stirring temperature is 50°C, then mix the essence mixture and the emulsifier solution according to the mass ratio of 10:1, and stir while adding, After stirring for 50 minutes, high-speed homogenization to obtain the microcapsule core material emulsion for subsequent use;

[0032] (3) chitosan is added to the acetic acid solution by the addition ratio of 0.5g chitosan / 100mL acetic acid solution to form a chitosan solu...

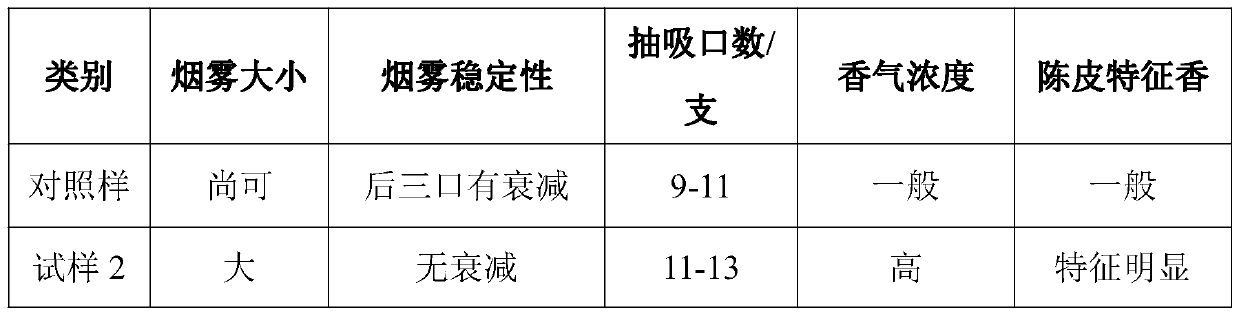

Embodiment 2

[0039] (1) Weigh 2g of methylcellulose and dissolve it in distilled water to prepare a methylcellulose aqueous solution with a concentration of 3wt%, and stir it for 80min with a stirring speed of 220rpm by a mechanical stirrer and use it as an emulsifier solution for subsequent use;

[0040] (2) Mix and stir tangerine peel essence and glycerin according to the mass ratio of 1:20 to obtain the essence mixture, stirring temperature is 50°C, then mix the essence mixture and nail emulsifier solution according to the mass ratio of 20:1, and stir while adding , after stirring for 60 minutes, high-speed homogenization to obtain the microcapsule core material emulsion for subsequent use;

[0041] (3) According to the addition ratio of 2g chitosan / 100mL acetic acid solution, chitosan is added to the acetic acid solution to form a chitosan solution with a concentration of 2.0wt%. Take 8g of sodium alginate and dissolve it in water to form a concentration of 8.0 The wt% sodium alginate ...

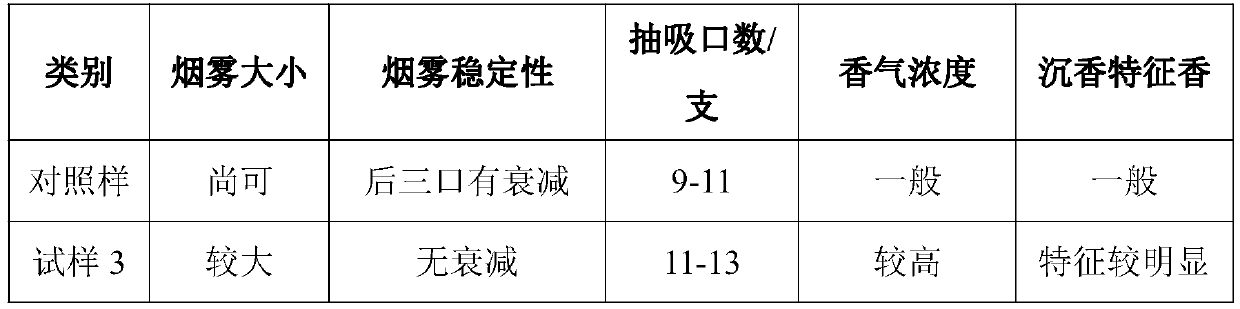

Embodiment 3

[0048](1) Weighing 1.5 g of methylcellulose and dissolving it in distilled water to prepare an aqueous solution of methylcellulose with a concentration of 2.0 wt%, and stirring it for 80 minutes with a stirring speed of 200 rpm by a mechanical stirrer to make an emulsifier solution for subsequent use;

[0049] (2) Mix and stir the essence of agarwood essence and glycerin at a mass ratio of 1:15 to obtain the essence mixture at a stirring temperature of 50°C, then mix the essence mixture and emulsifier solution at a mass ratio of 15:1, and stir while adding. After stirring for 50 minutes, high-speed homogenization to obtain the microcapsule core material emulsion for subsequent use;

[0050] (3) chitosan is added to the acetic acid solution by the addition ratio of 1.0g chitosan / 100mL acetic acid solution to form a chitosan solution with a concentration of 1.0wt% for subsequent use, and 8g sodium alginate is dissolved in water to form a concentration of The 8.0wt% sodium algina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com