Multi-layer composite heat preservation and insulation plate and preparation method thereof

A technology of thermal insulation board and thermal insulation layer, applied in the direction of chemical instruments and methods, layered products, carbon compounds, etc., can solve the problems of poor thermal insulation effect, large deformation coefficient, easy to burn, etc., and achieve increased thermal insulation Heat insulation effect, good thermal insulation performance, and enhanced flame retardant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

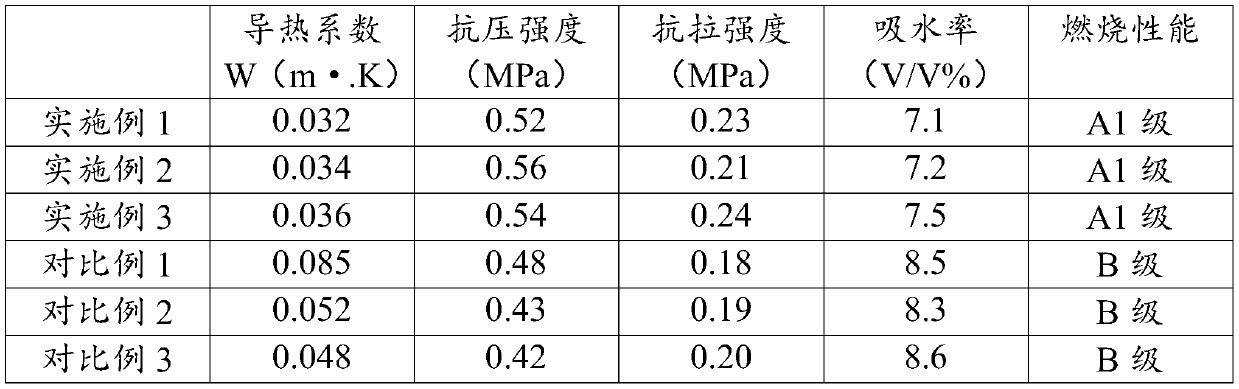

Embodiment 1

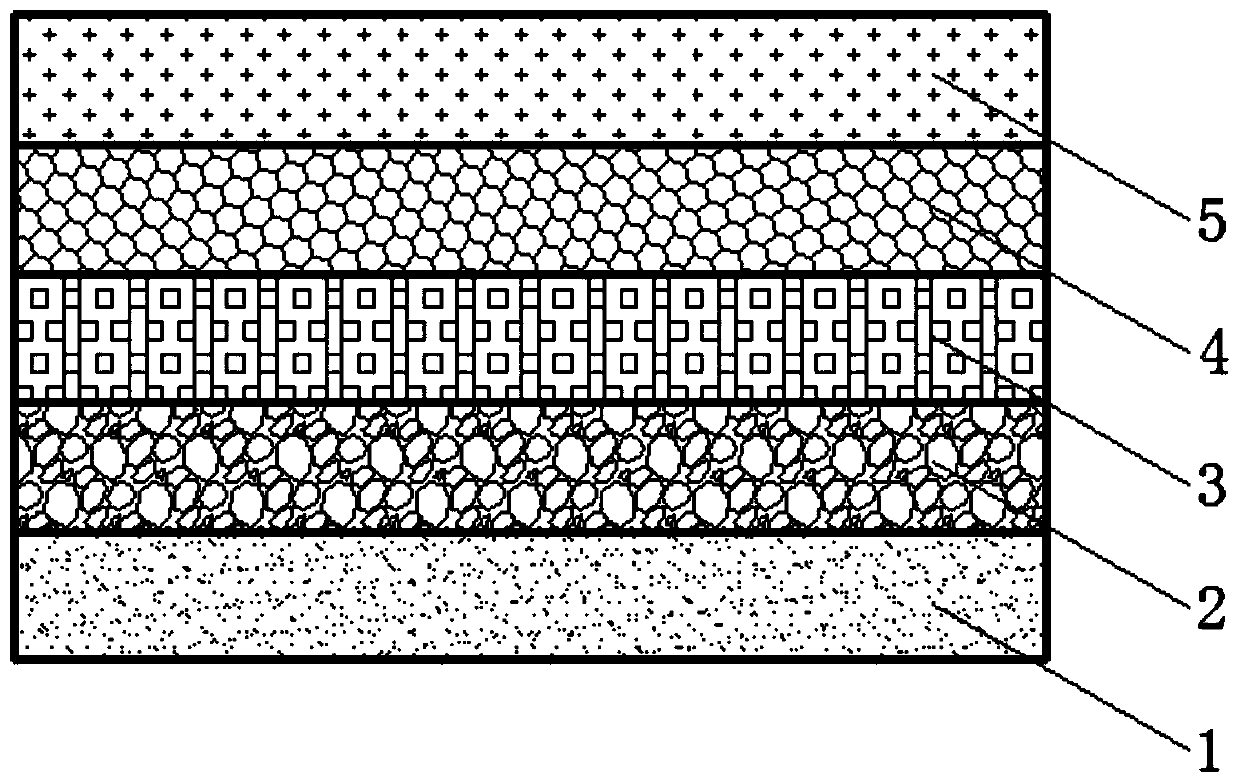

[0035] In the multi-layer composite thermal insulation board provided in this embodiment, the structure of the thermal insulation board from the inside to the outside is the bonding mortar layer 1, the reinforcement layer 2, the heat insulation layer 3, the flame retardant layer 4 and the decorative layer 5. Adhesive mortar layer 1, reinforcement layer 2, thermal insulation layer 3, flame retardant layer 4 and decorative layer 5 are bonded and pressed with an inorganic non-combustible adhesive to form an integrated structure, and the total thickness of the thermal insulation board is 15cm ;

[0036] The thermal insulation layer 3 is composed of the following components by weight: 32 parts of polystyrene foam particles, 6 parts of aluminum hydroxide, 6 parts of ceramic fiber, 6 parts of modified graphene oxide, and 2 parts of silane coupling agent.

[0037] Among them, the preparation method of the modified graphene oxide is: dissolving the weighed graphene oxide in deionized w...

Embodiment 2

[0048] In the multi-layer composite thermal insulation board provided in this embodiment, the structure of the thermal insulation board from the inside to the outside is the bonding mortar layer 1, the reinforcement layer 2, the heat insulation layer 3, the flame retardant layer 4 and the decorative layer 5. Adhesive mortar layer 1, reinforcement layer 2, thermal insulation layer 3, flame retardant layer 4 and decorative layer 5 are bonded and pressed with an inorganic non-combustible adhesive to form an integrated structure, and the total thickness of the thermal insulation board is 5cm ;

[0049] The thermal insulation layer 3 is composed of the following components by weight: 25 parts of polystyrene foam particles, 5 parts of aluminum hydroxide, 8 parts of ceramic fiber, 5 parts of modified graphene oxide, and 1 part of silane coupling agent.

[0050] Among them, the preparation method of the modified graphene oxide is: dissolving the weighed graphene oxide in deionized wat...

Embodiment 3

[0061] In the multi-layer composite thermal insulation board provided in this embodiment, the structure of the thermal insulation board from the inside to the outside is the bonding mortar layer 1, the reinforcement layer 2, the heat insulation layer 3, the flame retardant layer 4 and the decorative layer 5. Adhesive mortar layer 1, reinforcement layer 2, thermal insulation layer 3, flame retardant layer 4 and decorative layer 5 are bonded and pressed with an inorganic non-combustible adhesive to form an integrated structure, and the total thickness of the thermal insulation board is 20cm ;

[0062] The thermal insulation layer is composed of the following components by weight: 40 parts of polystyrene foam particles, 8 parts of aluminum hydroxide, 5 parts of ceramic fiber, 8 parts of modified graphene oxide, and 3 parts of silane coupling agent.

[0063] Among them, the preparation method of the modified graphene oxide is: dissolving the weighed graphene oxide in deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com