Manufacturing method of circuit board being capable of achieving high-density interconnection

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit components, electrical connection printed components, and electrical connection formation of printed components, can solve the problems of high manufacturing cost and complicated process, achieve simple process flow, reduce manufacturing difficulty and The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment provides a method for fabricating a circuit board for high-density interconnection, which includes a method for fabricating metallized sub-holes on the circuit board, including the following steps:

[0026] (1) Cutting: cut out the inner core board according to the panel size required by the design.

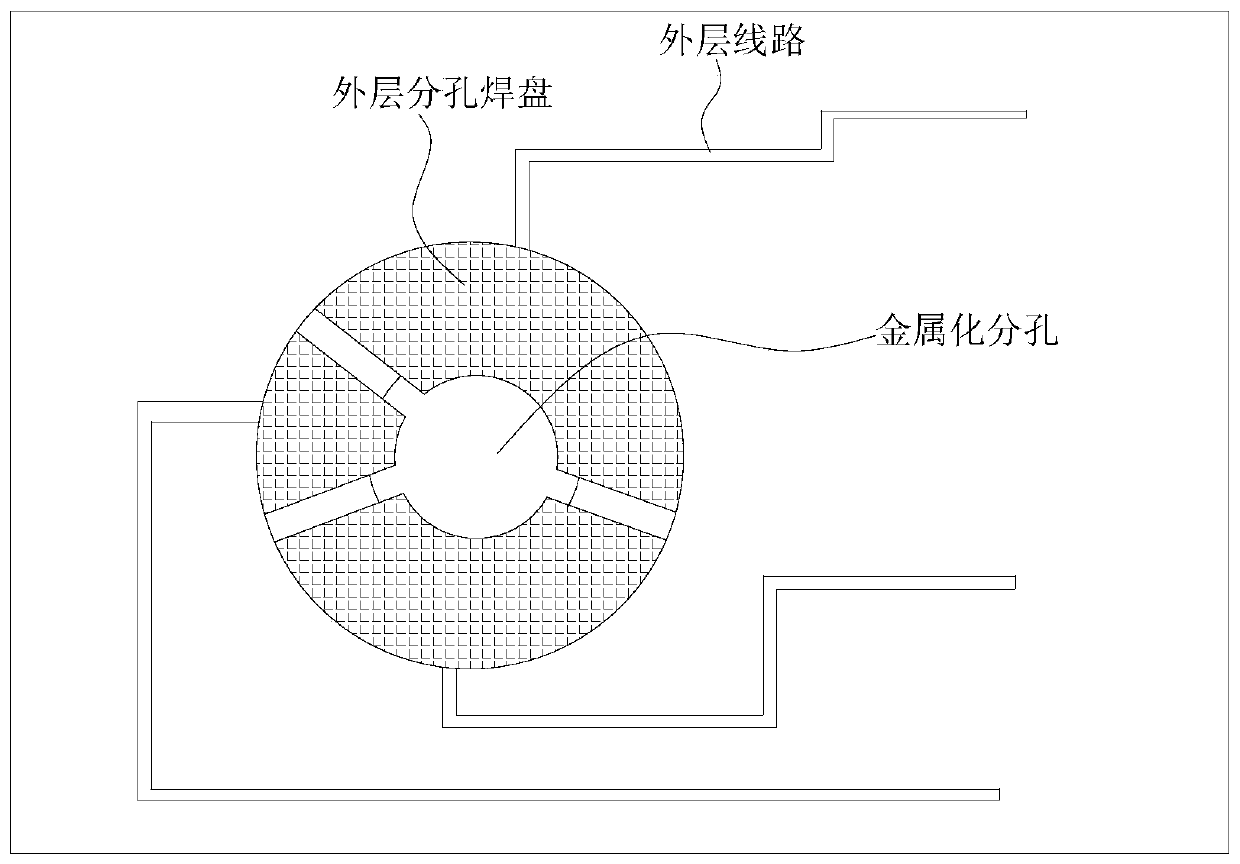

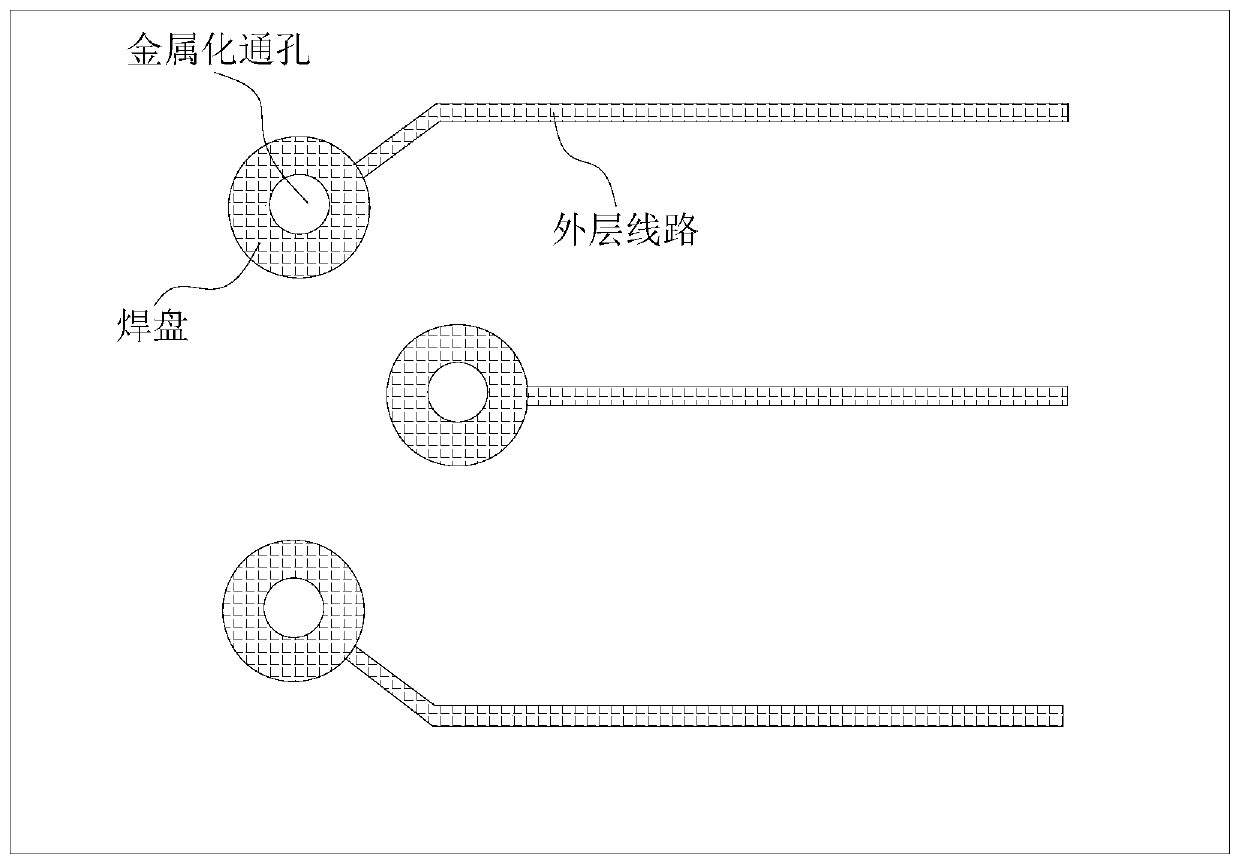

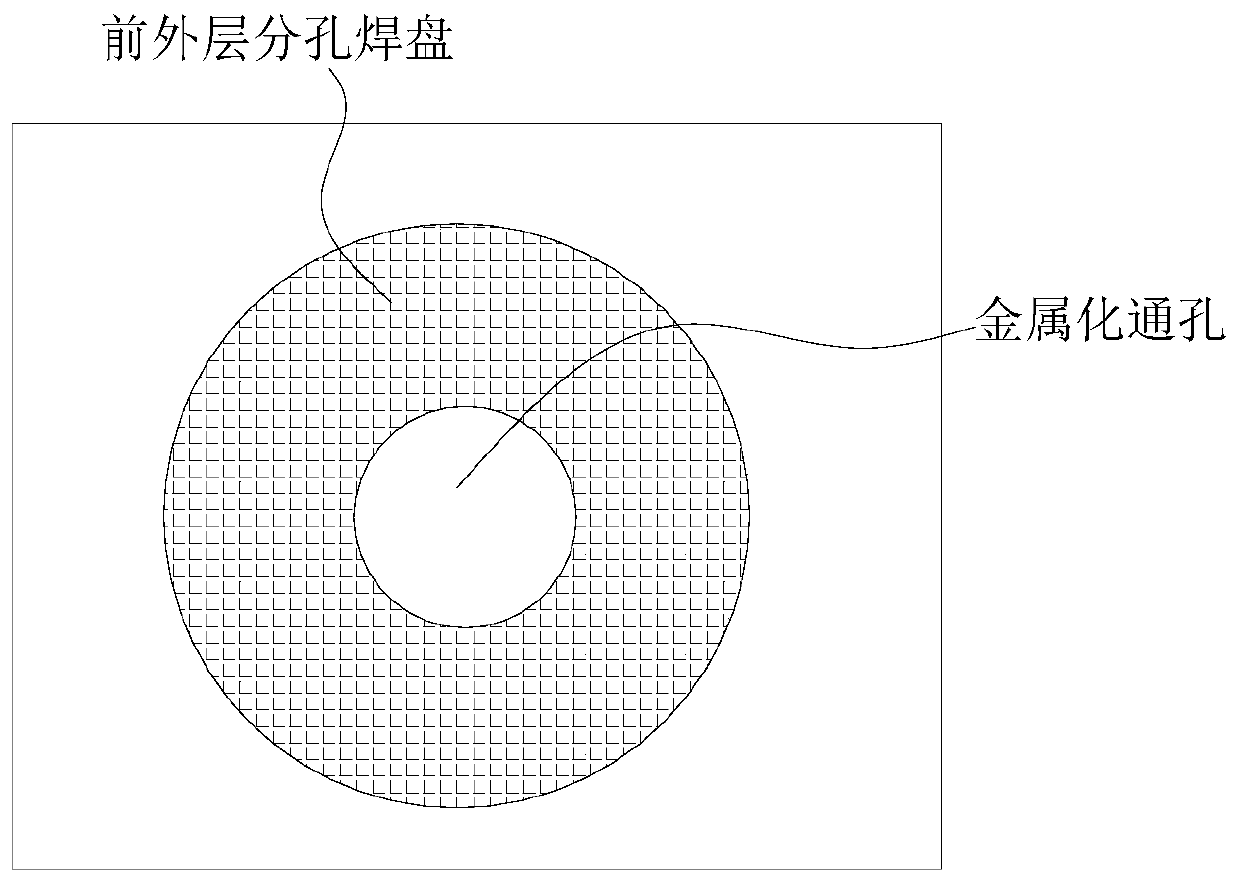

[0027] (2) Making the inner layer circuit: using the negative process to make the inner layer circuit on the inner layer core board to obtain the inner layer circuit board. The inner layer circuit includes an inner layer sub-hole pad for connection with the metallized vias that will be formed later. The inner layer sub-hole pad is composed of alternately spaced copper layers and substrate layers along the circumference, and the inner layer sub-holes The alternate arrangement of the copper layer and the substrate layer on the pad is the same as the setting of the outer layer sub-hole pad to be produced later. The copper layers of the layers are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com