Hydraulic adjusting device and one-way valve

A one-way valve and bonnet technology, applied in the hydraulic field, can solve the problems of reduced sealing performance, inclined spring, failure of the valve ball to block the channel, etc., and achieve the effect of high anti-bending ability and anti-tilting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It can be seen from the background art that during the assembly and working process of the check valve, there is a risk of the spring tilting, and the tilting of the spring will cause the valve ball to fail to perform the sealing function.

[0036] The reasons for the inclination of the spring are analyzed below.

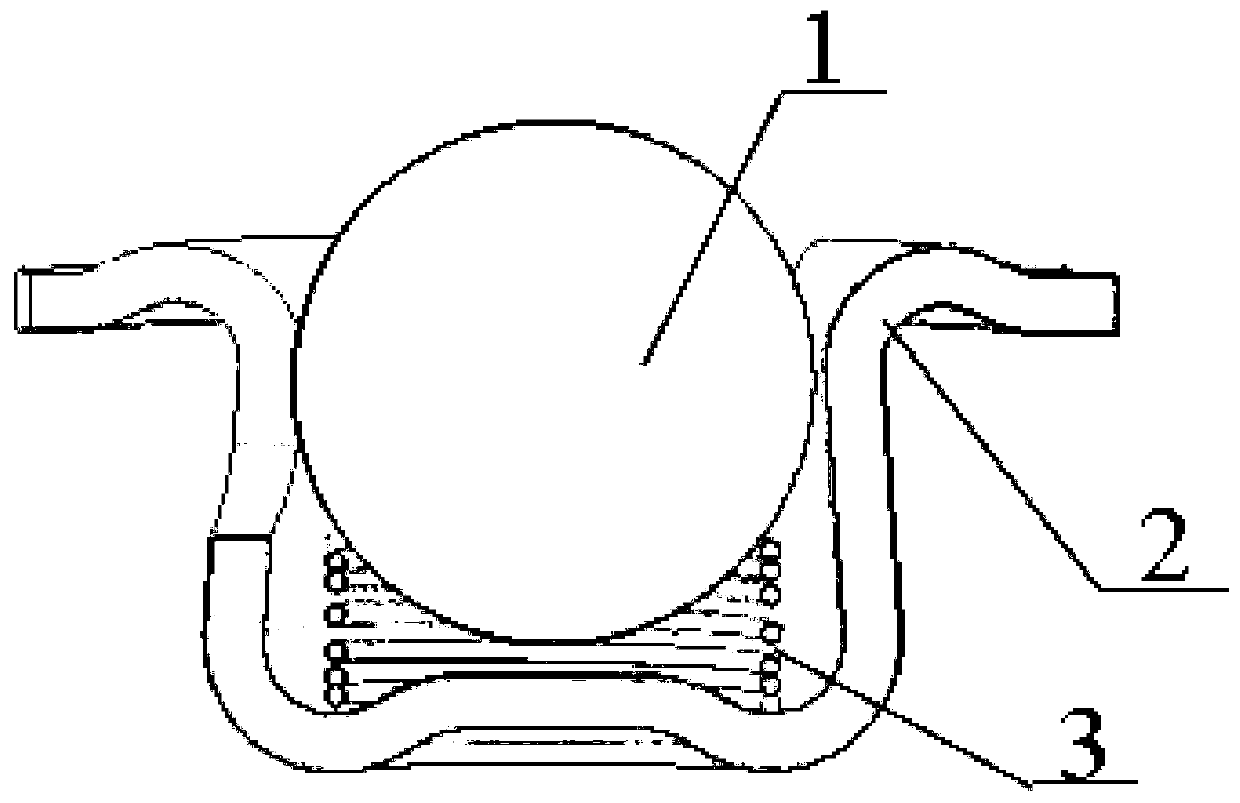

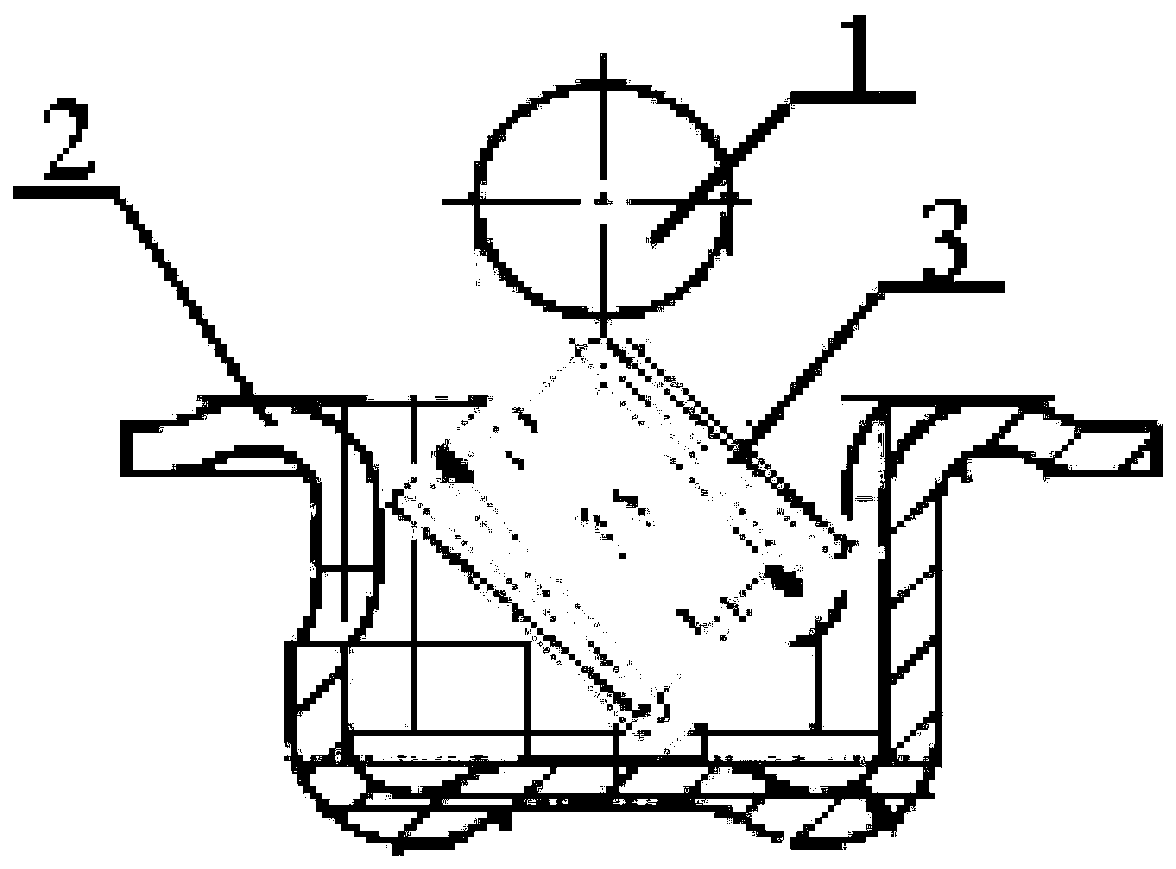

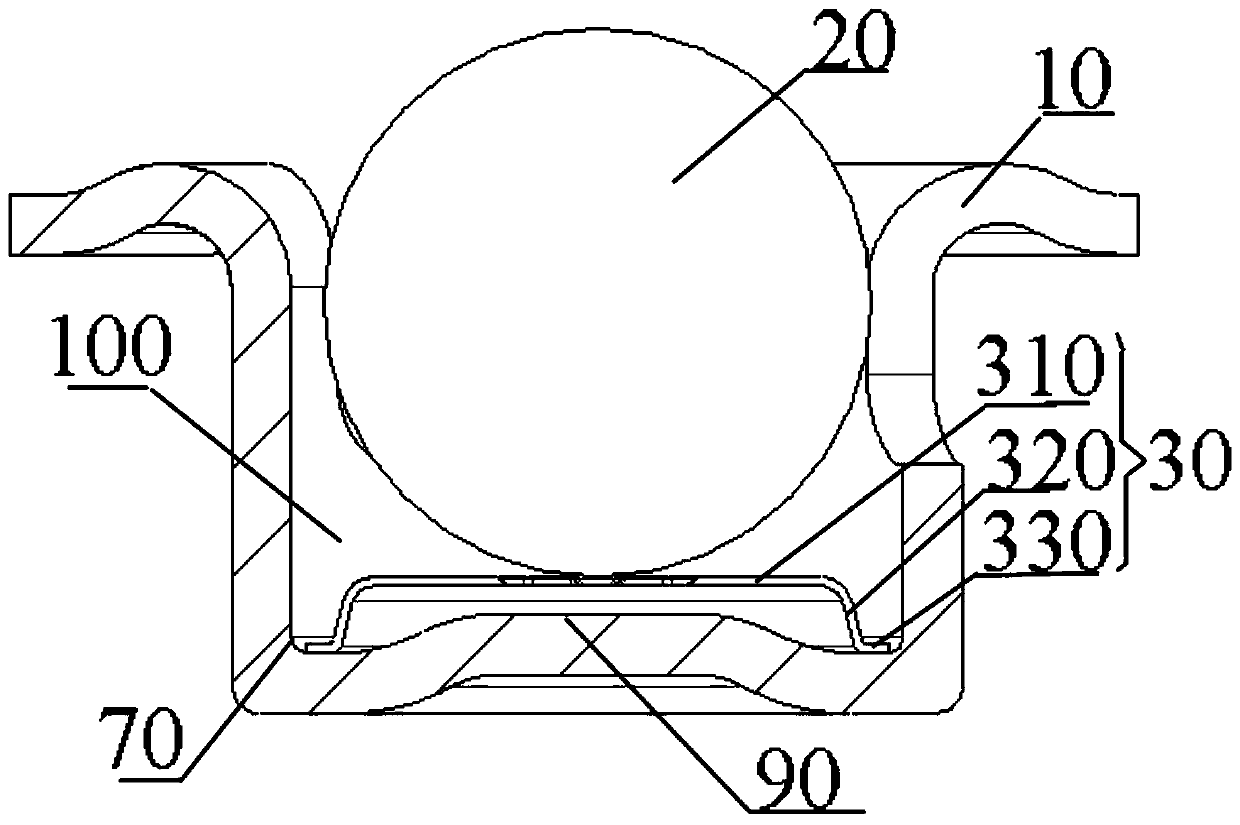

[0037] Please refer to figure 1 and figure 2 , figure 1 is a cross-sectional view of a one-way valve; figure 2 yes figure 1 A schematic diagram of the tilting of the spring of the one-way valve.

[0038] Such as figure 1 As shown, the check valve includes a valve ball 1, a bonnet 2 and a spring 3. During the assembly process, as figure 2 As shown, there is a risk of the spring tilting.

[0039] There are several reasons for the spring to tilt:

[0040] 1. Due to the limited performance of the equipment, it is difficult to control the dimensions of the spring, such as the inner diameter, free length, and closed coils at both ends. In addition, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com