Design method and weaving process of a three-layer thermal insulation fabric

A design method and fabric technology, applied in the field of fabric production, can solve the problems that the softness of the fabric is not as good as that of the knitted fabric, the thermal insulation effect of the fabric is affected, and the fit performance is poor, so as to achieve the effect of good comfort, high rigidity and improved warmth retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

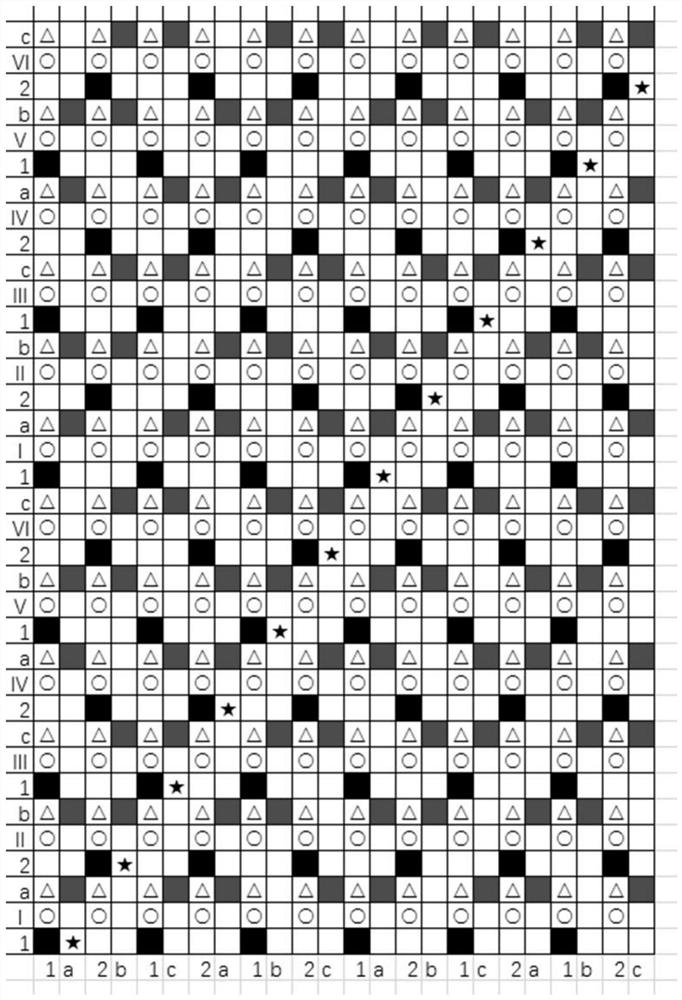

[0033] 1. Fabric specification

[0034] The width of the finished product is 146cm, the warp density of the finished product is 630 threads / 10cm, the weft density of the finished product is 828 threads / 10cm, the width of the gray cloth is 163.7cm, the warp density of the gray cloth is 562 threads / 10cm, the weft density of the gray cloth is 802 threads / 10cm, and the finishing shrinkage rate is 10.8%. Finishing length shrinkage rate is 3.2%, weft shrinkage rate is 6.2%, warp weaving shrinkage rate is 9.1%, upper machine reed width is 174.5cm, upper machine reed number is 132 reed / 10cm, surface warp, surface weft, inner warp, inner Layer weft yarns are all 13tex, middle layer weft yarn is acrylic 300D / 144f. The total number of warps of the full-width fabric is 9184, 44 in one flower cycle, 208 flowers in the whole width, 9152 in total in the ground warp, 4576 in the surface warp and 4576 in the inner warp, and 32 side yarns, the side yarn and the surface layer The warp is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com