Technical method for jacquard tussah silk warm mat

A process method, jacquard technology, applied in the direction of digging fabrics, textile materials processing, weaving, etc., can solve the problems of not seeing, etc., achieve the function of increasing heat preservation, convenient and fast pattern transmission, good comfort and heat preservation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] A process method for jacquard tussah silk warm mat,

[0026] (1) Preparation process

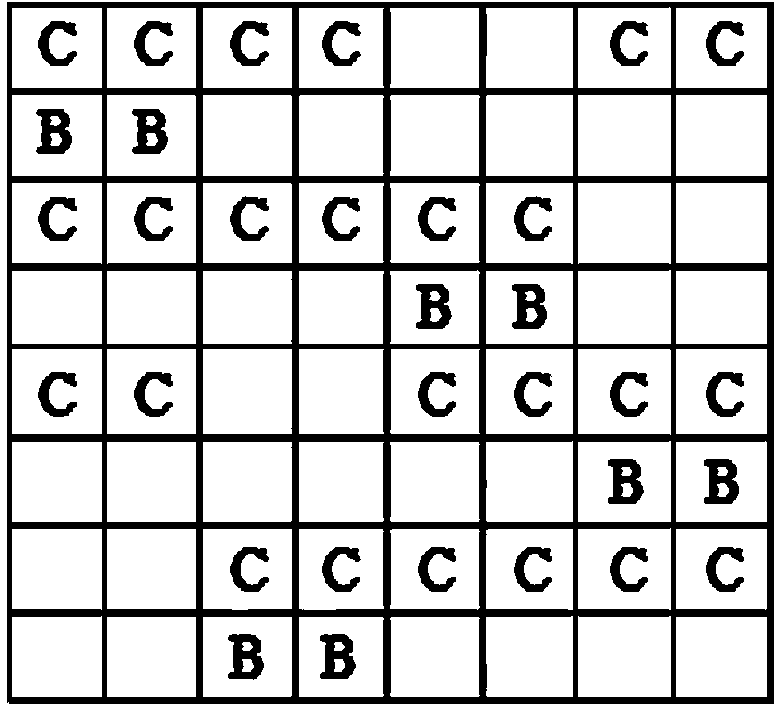

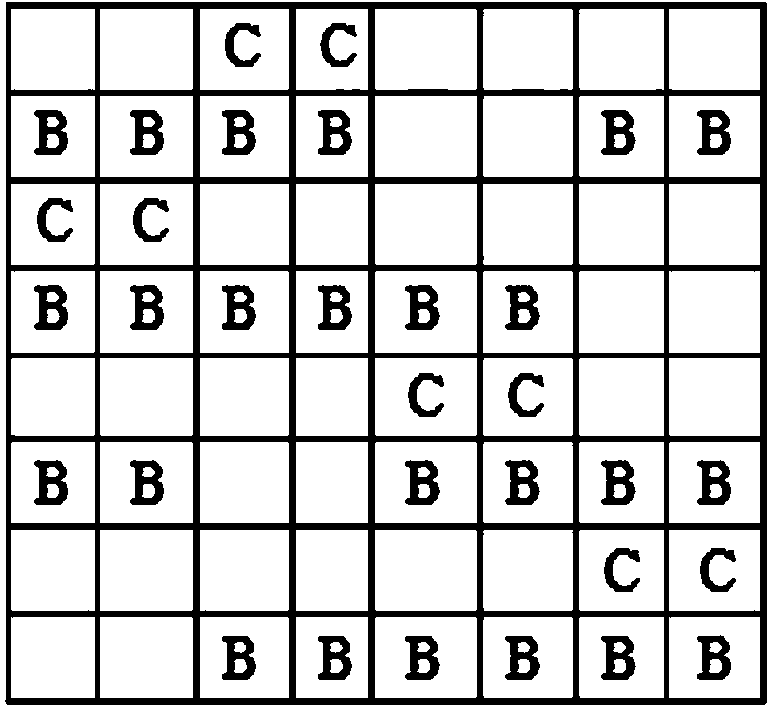

[0027] Warp: 1 / 60 S / 2 Cotton yarn warping directly;

[0028] Weft: A latitude 1 / 40 N / 2 spun yarn - weaving;

[0029] B weft 1 / 40 S / 2 heat-retaining yarn is plied and added 6T before weaving.

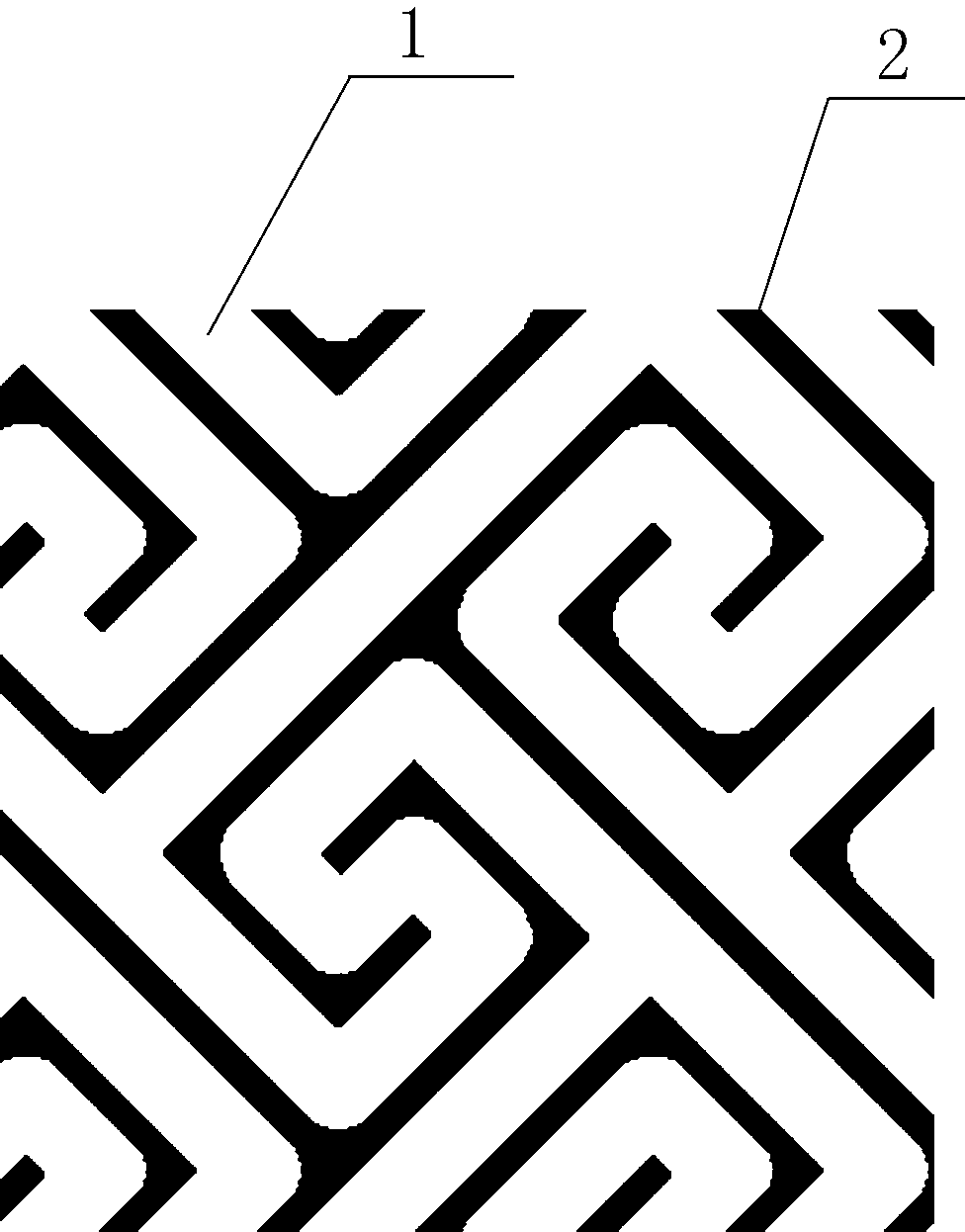

[0030] The structure of the present invention is as figure 1 shown.

[0031] Raw material selection:

[0032] Warp A: 1 / 60 S / 2 cotton yarn;

[0033] Weft B: Jia weft 1 / 40 N / 2 silk yarn;

[0034] B Wei 2 / 40 S / 2 thermal yarn right 6T.

[0035] According to the functions and characteristics of coffee carbon fiber, the determination of the proportion and composition of coffee carbon fiber and other fiber blends is very important to the product. Proper use will not only increase the warmth function of the bedding, but also improve the quality and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com