Perfluoropolyether siloxane compound and synthesis method and application thereof

A technology of perfluoropolyether siloxane and synthesis method, which is applied in polyether coatings, biocide-containing paints, coatings, etc., can solve the problem of poor antifouling performance, inability to provide sufficient adhesion, wear resistance and Durability, low ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

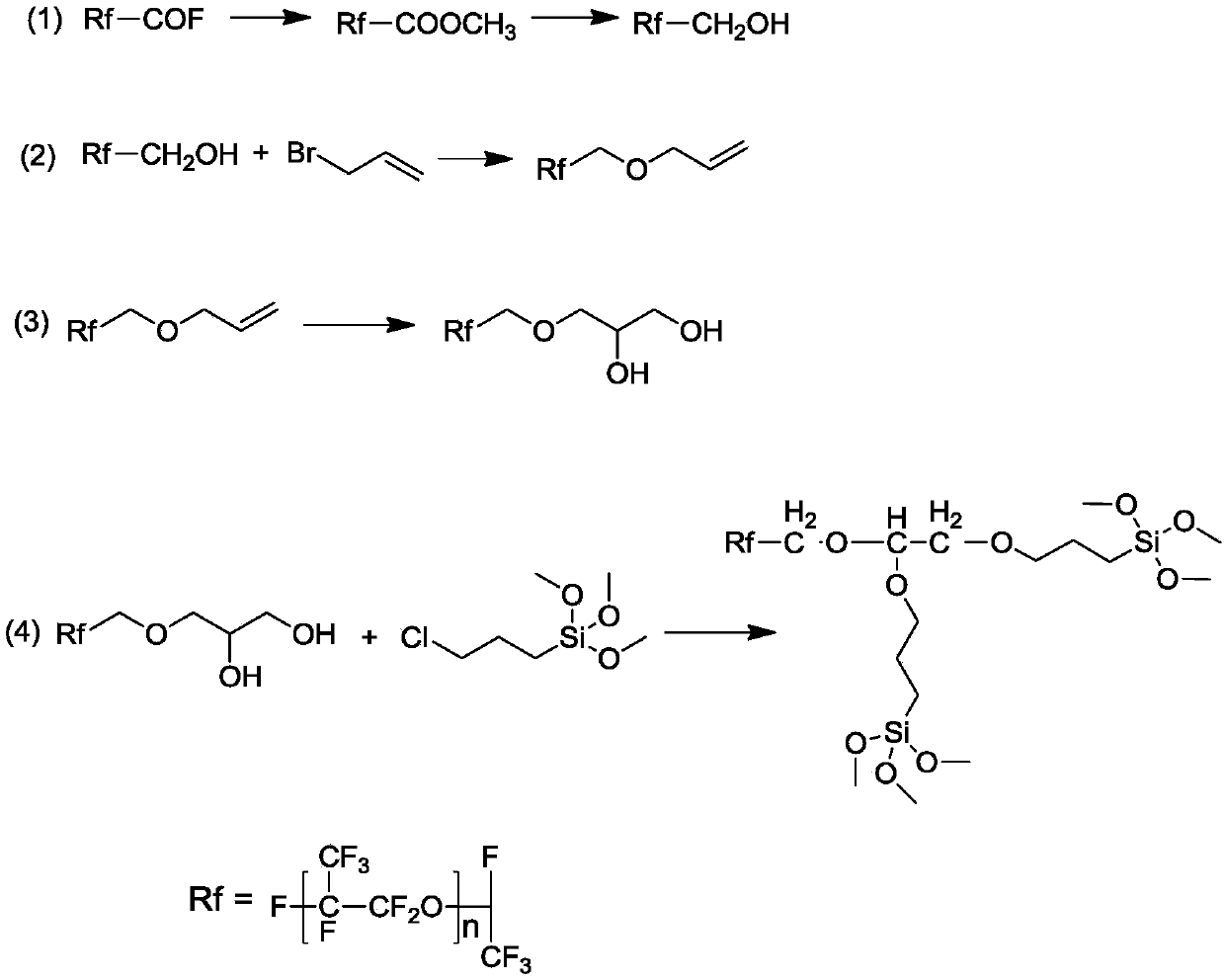

Method used

Image

Examples

Embodiment 1

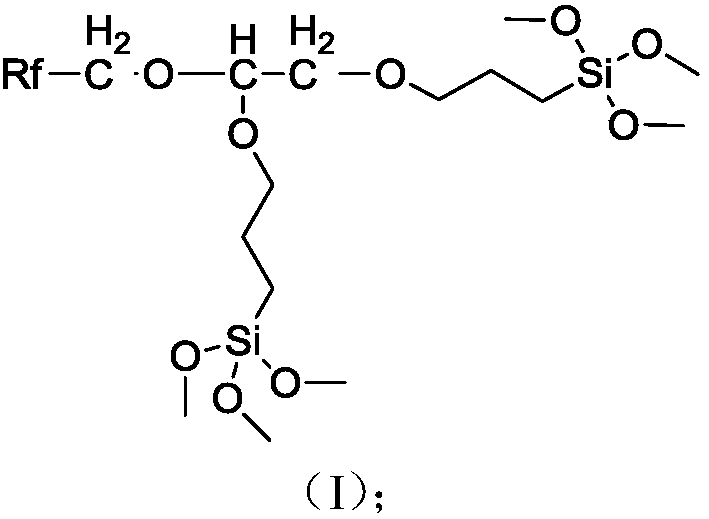

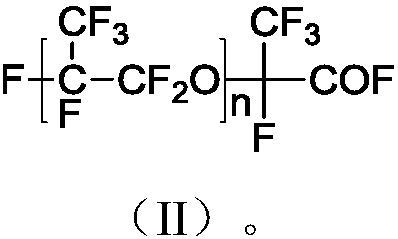

[0084] (1) 300g perfluoropolyether acid fluoride (n=12, Mw=2158g / mol) and 44.49g methanol were stirred and reacted at room temperature for 24h, the molar ratio of perfluoropolyether acid fluoride to methanol was 1:10, and the reaction At the end, the reaction mixture was placed in a separatory funnel, washed three times with methanol, and the lower layer sample was distilled under reduced pressure to obtain perfluoropolyether methyl ester. Add 100g of perfluoropolyether methyl ester (Mw=2170g / mol) in the three-necked flask, add a total of 10.46g of NaBH in 3 times 4 , perfluoropolyether methyl ester and NaBH 4 The molar ratio is 1:6, add 200mL of absolute ethanol, and stir at room temperature under nitrogen protection for 24h to obtain perfluoropolyether methanol.

[0085] (2) Under nitrogen protection, add 50g of perfluoropolyether methanol (Mw=2142g / mol) and 3.41g of potassium tert-butoxide into a three-necked flask, add 75mL of tert-butanol as a reaction solvent, and then ...

Embodiment 2

[0089] (1) 300g perfluoropolyether acid fluoride (n=17, Mw=2988g / mol) and 64.26g methanol were stirred and reacted at room temperature for 24h, the molar ratio of perfluoropolyether acid fluoride to methanol was 1:20, and the reaction At the end, the reaction mixture was placed in a separatory funnel, washed three times with methanol, and the lower layer sample was distilled under reduced pressure to obtain perfluoropolyether methyl ester. Add 100g of perfluoropolyether methyl ester (Mw=3000g / mol) into the three-necked flask, add a total of 8.20g of NaBH in 3 times 4 , perfluoropolyether methyl ester and NaBH 4 The molar ratio is 1:6.5, add 200mL of absolute ethanol, stir and react at room temperature under nitrogen protection for 24h, and obtain perfluoropolyether methanol.

[0090] (2) Under the protection of nitrogen, add 50g of perfluoropolyether methanol (Mw=2972g / mol) and 2.45g of potassium tert-butoxide into a three-necked flask, add 75mL of tert-butanol as a reaction ...

Embodiment 3

[0094] (1) 300g perfluoropolyether acid fluoride (n=25, Mw=4316g / mol) and 44.49g methanol were stirred and reacted at room temperature for 24h, the molar ratio of perfluoropolyether acid fluoride to methanol was 1:20, and the reaction At the end, the reaction mixture was placed in a separatory funnel, washed three times with methanol, and the lower layer sample was distilled under reduced pressure to obtain perfluoropolyether methyl ester. Add 100g of perfluoropolyether methyl ester (Mw=4328g / mol) in the three-necked flask, add a total of 6.99g of NaBH in 3 times 4 , perfluoropolyether methyl ester and NaBH4 The molar ratio is 1:8, add 200mL of absolute ethanol, and stir at room temperature under nitrogen protection for 24h to obtain perfluoropolyether methanol.

[0095] (2) Under the protection of nitrogen, add 50g of perfluoropolyether methanol (Mw=4300g / mol) and 1.96g of potassium tert-butoxide into a three-necked flask, add 75mL of tert-butanol as a reaction solvent, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com