Pressure stabilizing and water supplying device for thick plate after-rolling cooling system high-pressure section and method thereof

A technology of cooling system and water supply device, which is applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., which can solve the problem that the pressure changes easily and fluctuates greatly, and the speed and accuracy of adjustment cannot meet the needs of rapid variable flow head and tail occlusion of steel plates. Changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

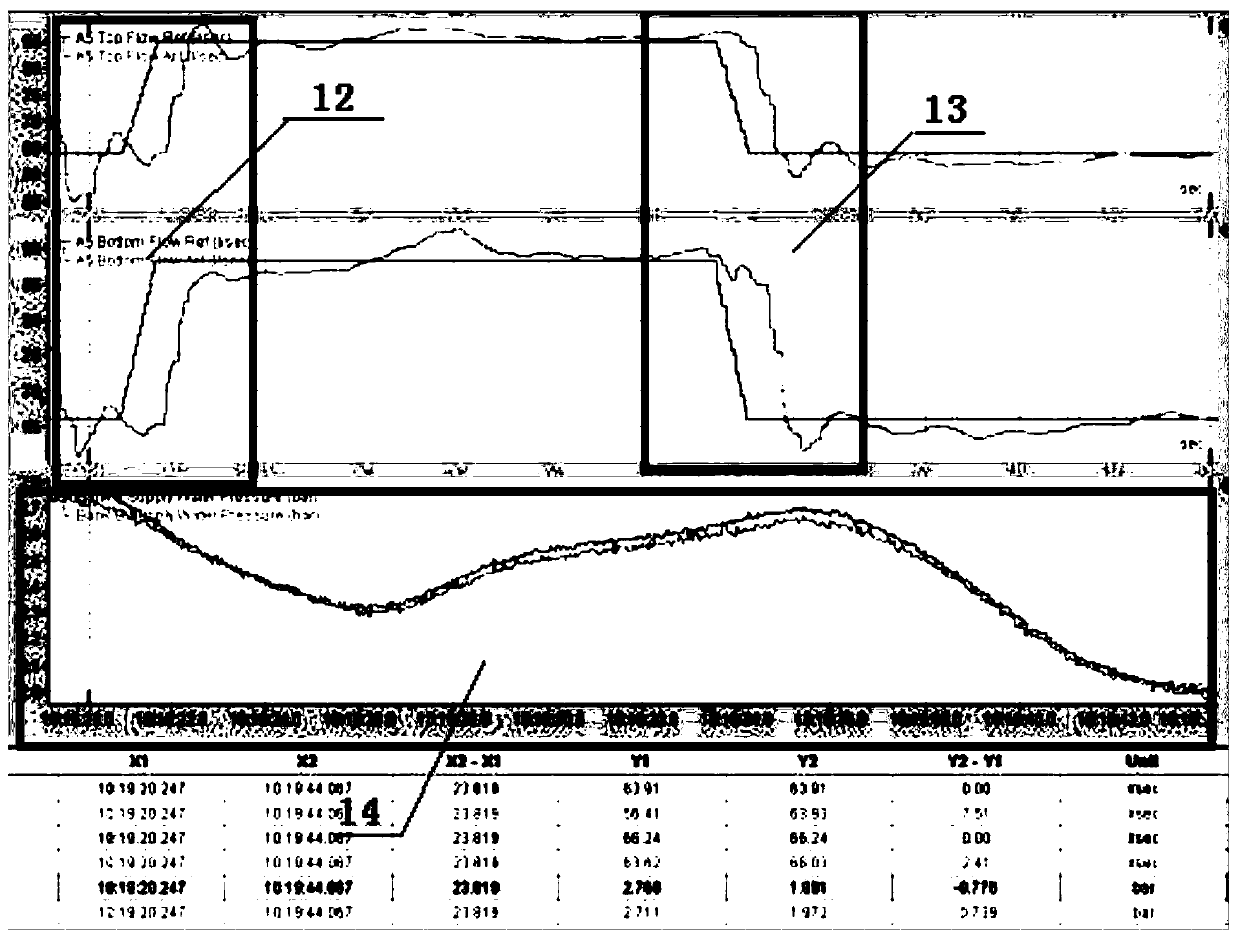

[0039] Without the voltage stabilizing device and its method, when the head and tail shielding amount of steel plate variable flow rate, the shielding amount of the upper table reaches 25%, the shielding amount of the lower table reaches 33%, and the fluctuation range of the water supply pressure of the middle water collection pipe of the high pressure section can reach 28.07% (the maximum pressure 0.2768MPa, the minimum pressure is 0.1991MPa). Correlation curve see below image 3 .

Embodiment 2

[0041] Using the pressure stabilizing device and its method, when the steel plate variable flow rate is blocked from the head to the tail, the blocking amount of the upper and lower tables reaches 40%, and the pressure fluctuation range of the middle water collection pipe in the high pressure section is only 8.05% (the maximum pressure is 0.3017MPa, and the minimum pressure is 0.2774MPa ), the pressure fluctuation range is significantly reduced. Correlation curve see Figure 4 .

Embodiment 3

[0043] When the head and tail of the steel plate variable flow are blocked, the blocking amount of the upper table reaches 38%, and the blocking amount of the lower table reaches 40%. The maximum opening degree of the voltage stabilizing regulating valve is 15.144 degrees under closed-loop control, and the pressure fluctuation range of the middle water collection pipe of the high-pressure section is 5.97% ( The maximum pressure is 0.269669MPa, and the minimum pressure is 0.253581MPa). Correlation curve see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com