Production device of thin film switch

A membrane switch and production device technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of high glue requirements, poor product durability, and many production processes, and achieve high work efficiency, accurate injection molding, positioning and injection molding The effect of process coherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

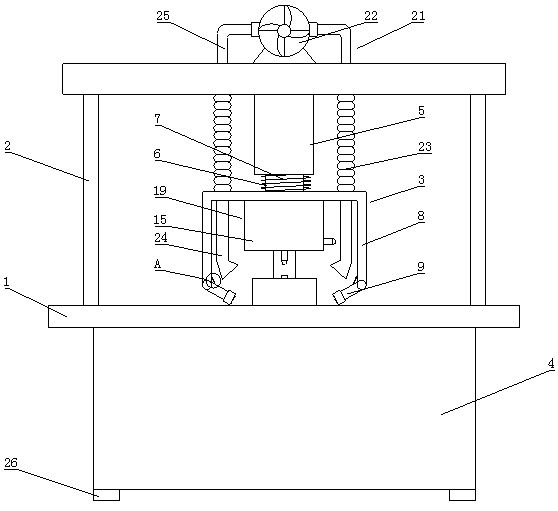

[0027] Such as Figure 1-4 as shown, figure 1 It is a structural schematic diagram of a production device for a membrane switch proposed by the present invention.

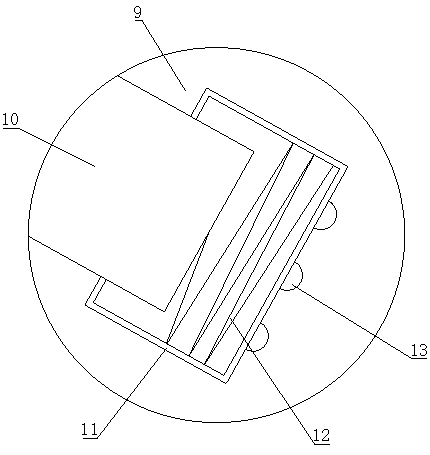

[0028] figure 2 It is a cross-sectional view of an outer positioning sleeve in a production device of a membrane switch proposed by the present invention.

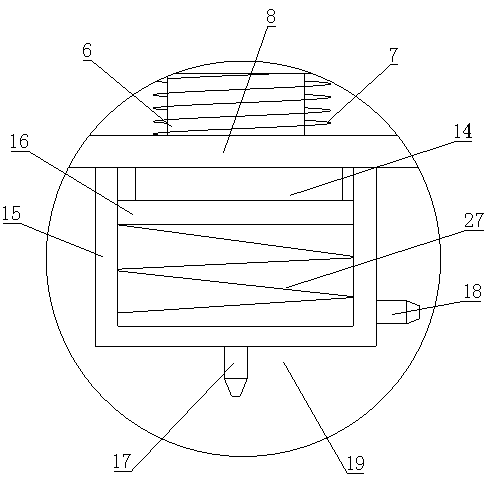

[0029] image 3 It is a cross-sectional view of a material storage tank in a membrane switch production device proposed by the present invention.

[0030] Figure 4 It is a partially enlarged schematic diagram of A in the production device of a membrane switch proposed by the present invention.

[0031] refer to Figure 1-4 , the production device of a kind of membrane switch that the present invention proposes, comprises console 1, mounting frame 2, positioning assembly 3, discharge assembly 19 and base 4; Mounting frame 2 is arranged on console 1; Positioning assembly 3 is installed on installation The horizontal section of the frame 2 includes a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com