Preparation method of high-conductivity heat-resistant aluminum alloy wire

A technology of aluminum alloy wires and aluminum alloy conductors, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductors, etc., can solve the problems of poor tensile strength of steel-cored aluminum stranded wires, limitation of overhead laying spans, heat resistance and Poor roundness and other problems, to achieve the effect of reducing the height of the pole, ensuring the mechanical properties of the resin, and improving the high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

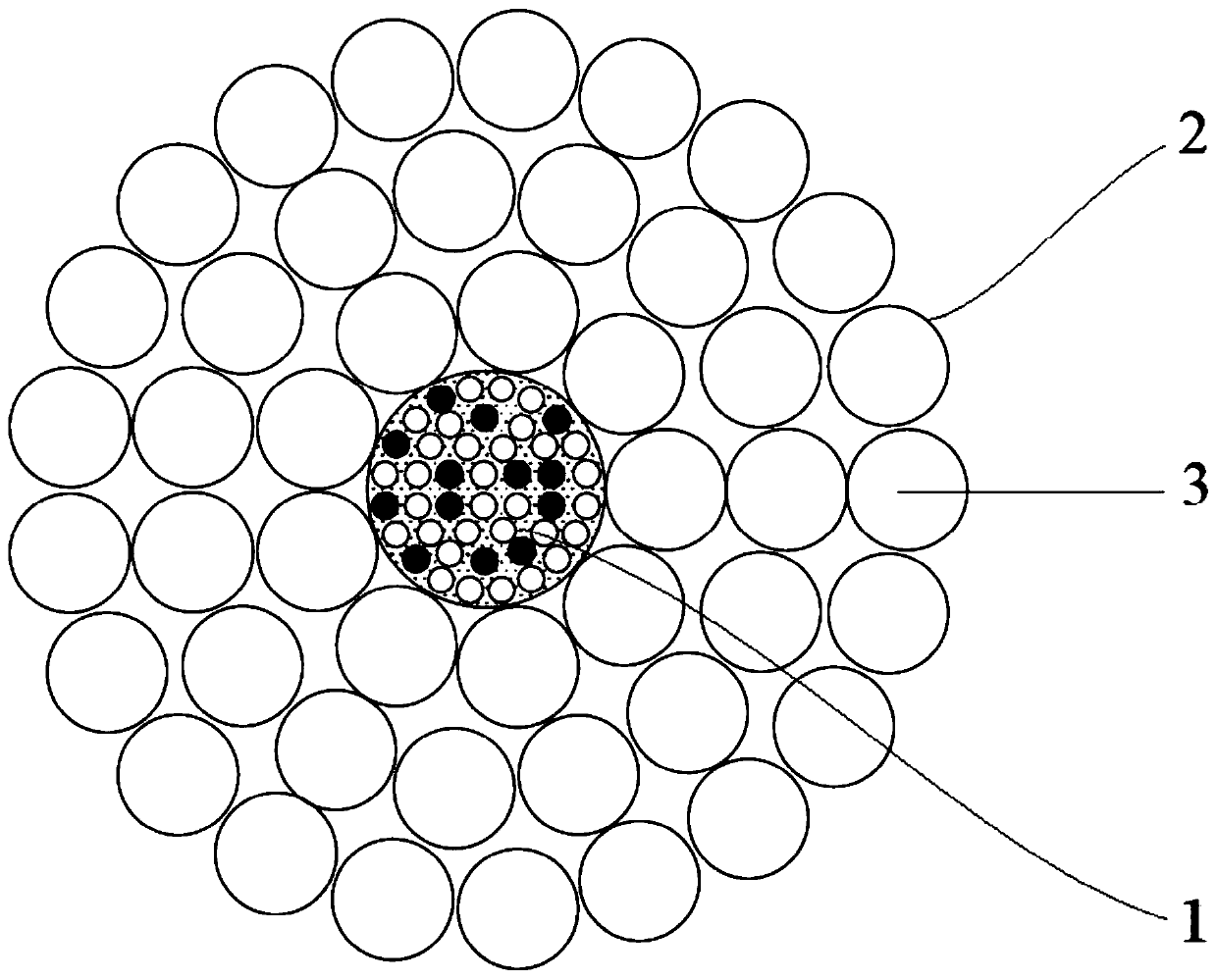

[0024] Embodiments 1 to 4: A method for preparing a high-conductivity heat-resistant aluminum alloy wire, the high-conductivity heat-resistant aluminum alloy wire includes a composite fiber reinforced core 1 and an aluminum alloy conductor layer 2, the aluminum alloy conductor layer 2 is made of stranded Composed of aluminum alloy single wires 3 outside the composite fiber reinforced core 1;

[0025] The preparation method of the high-conductivity heat-resistant aluminum alloy wire comprises the following steps:

[0026] S1. Put the carbon fiber and basalt fiber on the creel and divide the yarn, adjust the tension of each carbon fiber and basalt fiber to 0.3~0.4kg, dehydrate the carbon fiber and basalt fiber with adjusted tension and straightness, and then draw Wetting the thermosetting resin composition through a constant temperature glue tank;

[0027] S2. The carbon fiber and basalt fiber soaked in the thermosetting resin composition are solidified and formed through a the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com