Experimental equipment and method for measuring multi-angle burning rate of propellant in overload condition

An experimental device and propellant technology, applied in the direction of measuring device, velocity/acceleration/impact measurement, fluid velocity measurement, etc., can solve problems such as combustion effects, and achieve the effects of easy implementation, authentic experimental data, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

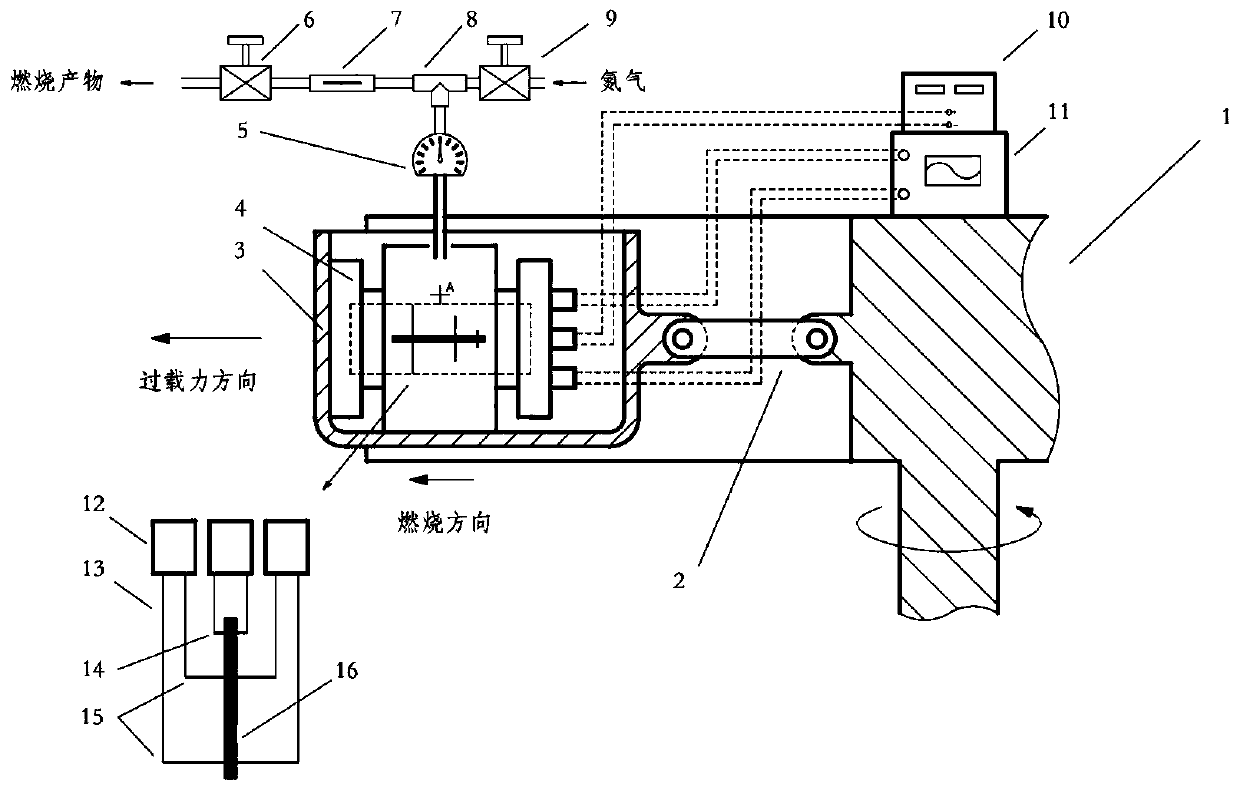

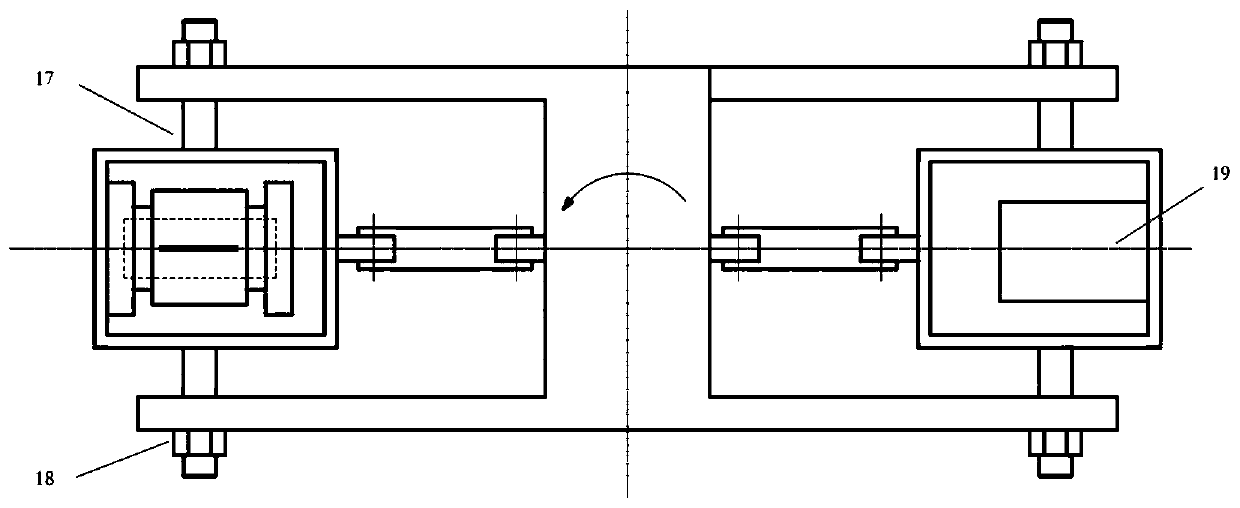

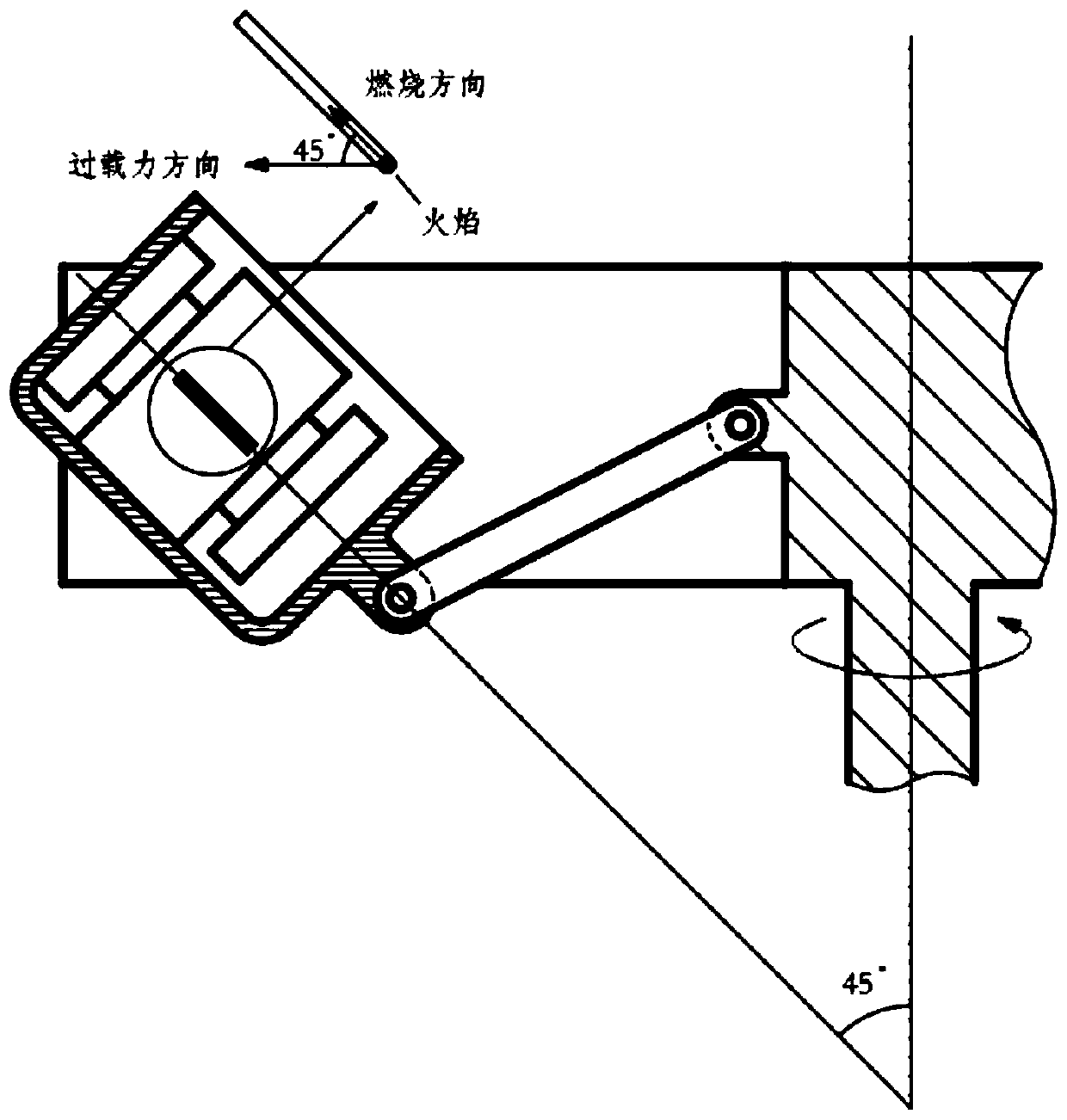

[0021] Such as figure 1 , 2 As shown, the experimental device disclosed by the present invention for measuring the multi-angle burning rate of propellants under overload conditions includes a rotary test bench 1, a connecting rod 2, a tray 3, a burner 4, a pressure sensor 5, an exhaust valve 6, a filter 7, tee joint 8, intake valve 9, power supply 10, signal acquisition instrument 11, electrical connector 12, wire 13, heating wire 14, target wire 15, propellant 16, mandrel 17, fixing nut 18 and accessories Heavy block 19.

[0022]Connection relationship: propellant The propellant 16 is fixed in the burner 4, and the propellant 16 has three small holes along the radial direction, through which the heating wire 14 and the two target wires 15 respectively pass, and the power supply 10 is used to energize the heating wire 14 , the heating wire 14 generates heat and ignites the propellant 16, and the flame spreads from one end to the other. Two target lines 15 for measuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com