3D printing-based layered prefabricated defect coal and rock mass sample preparation device and method

A prefabricated defect and 3D printing technology, applied in the field of rock mechanics, can solve the problems of rock-like sample model difficulty, small optional range, and small sample size, so as to shorten the production time, save labor capacity, and save test pieces. Angle-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

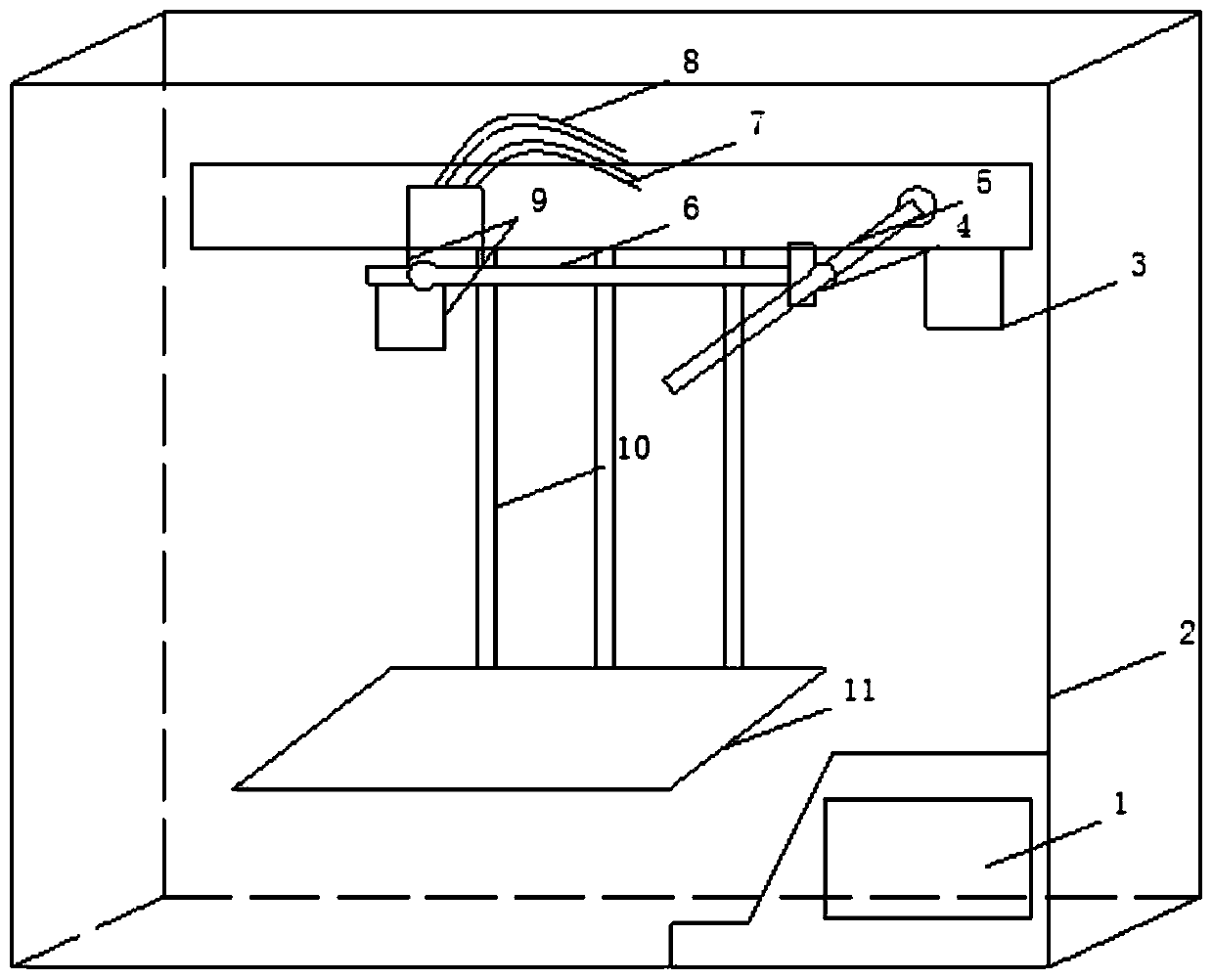

[0039] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

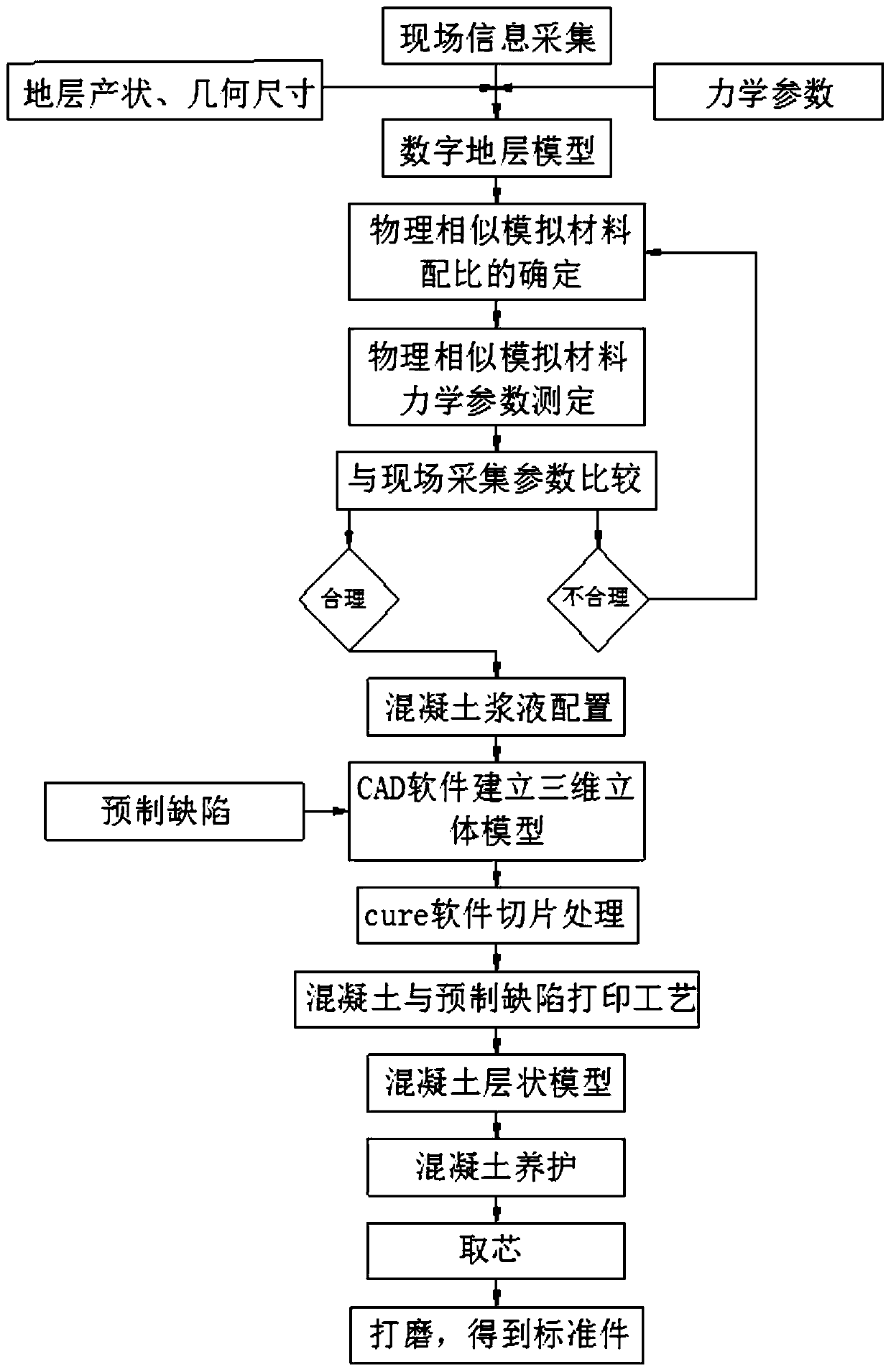

[0040] Such as figure 1 , figure 2 As shown, the layered prefabricated defective coal rock sample preparation method based on 3D printing of the present invention comprises the following steps:

[0041] Step 1: On-site collection of structural mechanical parameters of layered coal rock mass in underground coal-measure strata. Analyze and determine the structural parameters such as the occurrence, thickness, and lithology of each layer of coal or rock according to the comprehensive columnar diagram of coal-measure strata in the mining area or mine field; use photography and sketching methods to record random joints, cracks, faults, etc. that occur in coal seams or rock layers Engineering geological characteristics (joints, fissure lengths, angles, strike density, etc.); on-site corin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com