Ball valve sealing seat test mould and use method

A test mold and sealing seat technology, which is used in fluid tightness testing, machine/structural component testing, measuring devices, etc., can solve the problem of not being able to guarantee the sealing performance of the second valve seat assembly, adverse effects on material properties, and delaying construction periods. and other problems, to achieve the effect of improving the qualification rate of one-time assembly, avoiding adverse effects and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

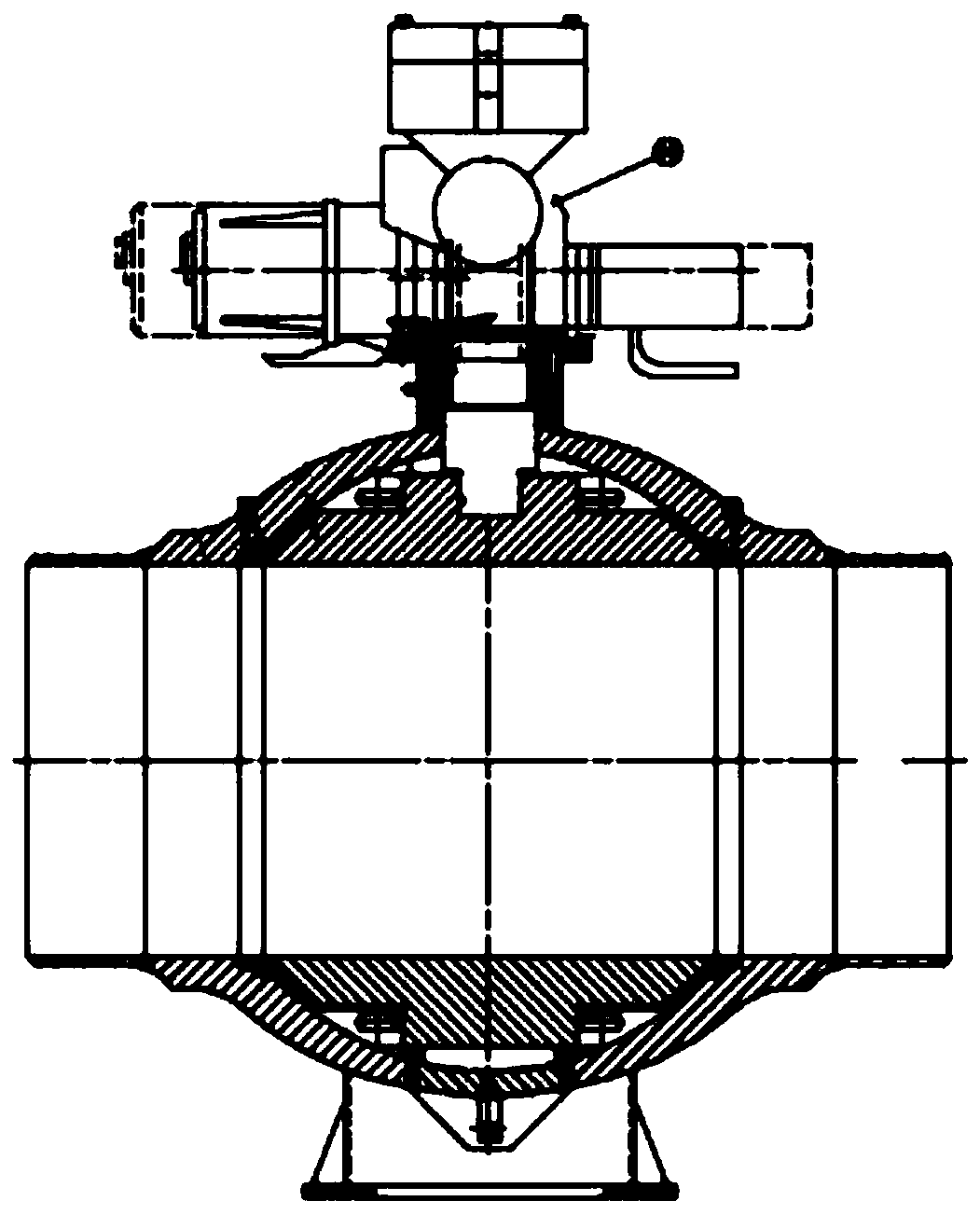

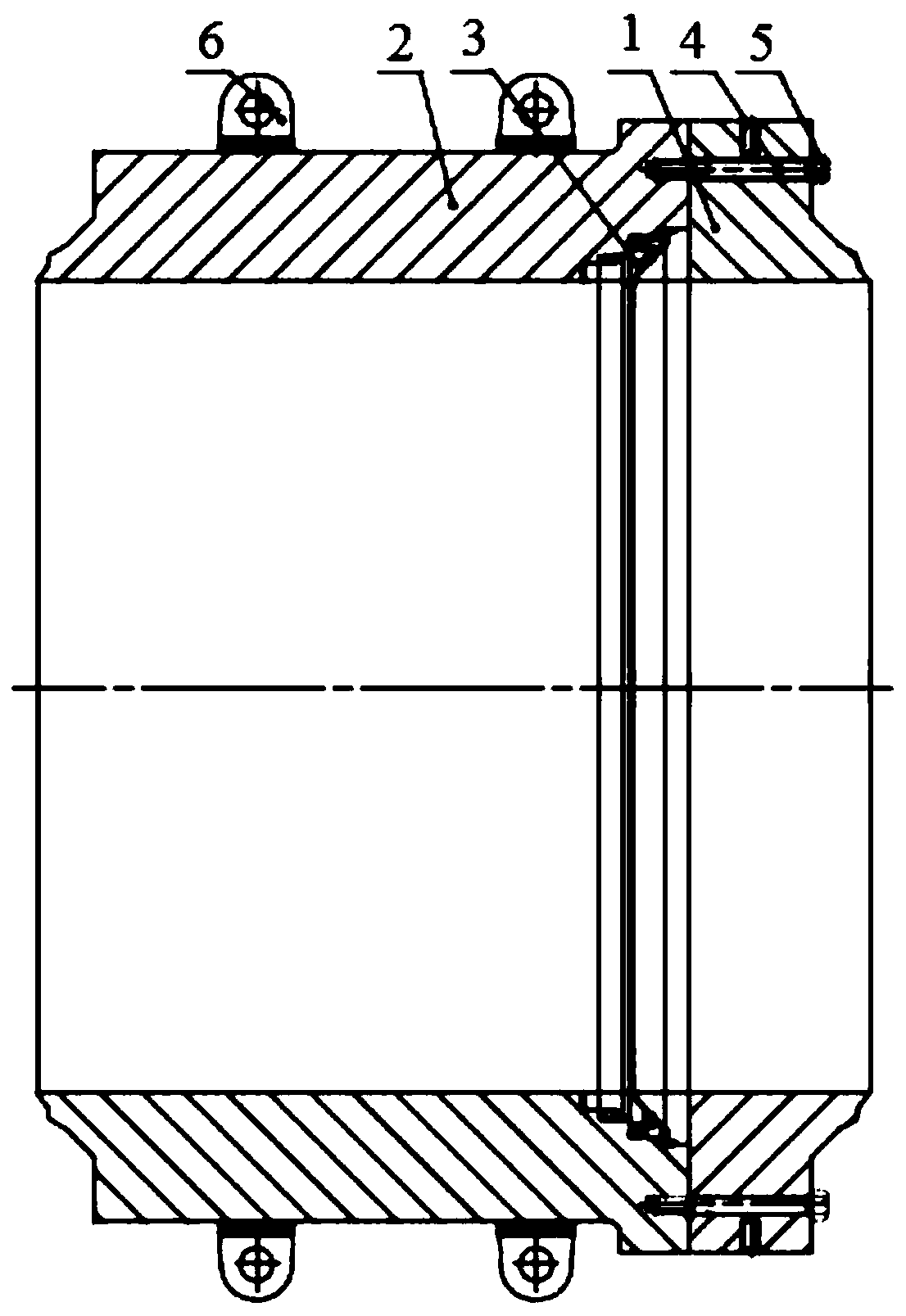

[0020] Embodiments of the present invention relate to a kind of ball valve sealing seat test mold, such as figure 1 As shown, it includes an upper mold 1 and a lower mold 2, the upper mold 1 is used to simulate the ball of a fully welded valve, and is connected to the ball installation end of the valve seat assembly 3 to be tested, and the lower mold 2 is used to simulate a fully welded valve The valve body is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com