Pneumatic proportional valve based on MEMS microfluidic chip

A technology of microfluidic chip and pneumatic proportional valve, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of no proportional adjustment function, complex structure, difficult to control, etc., and achieve stable air pressure, small structure, fast The effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

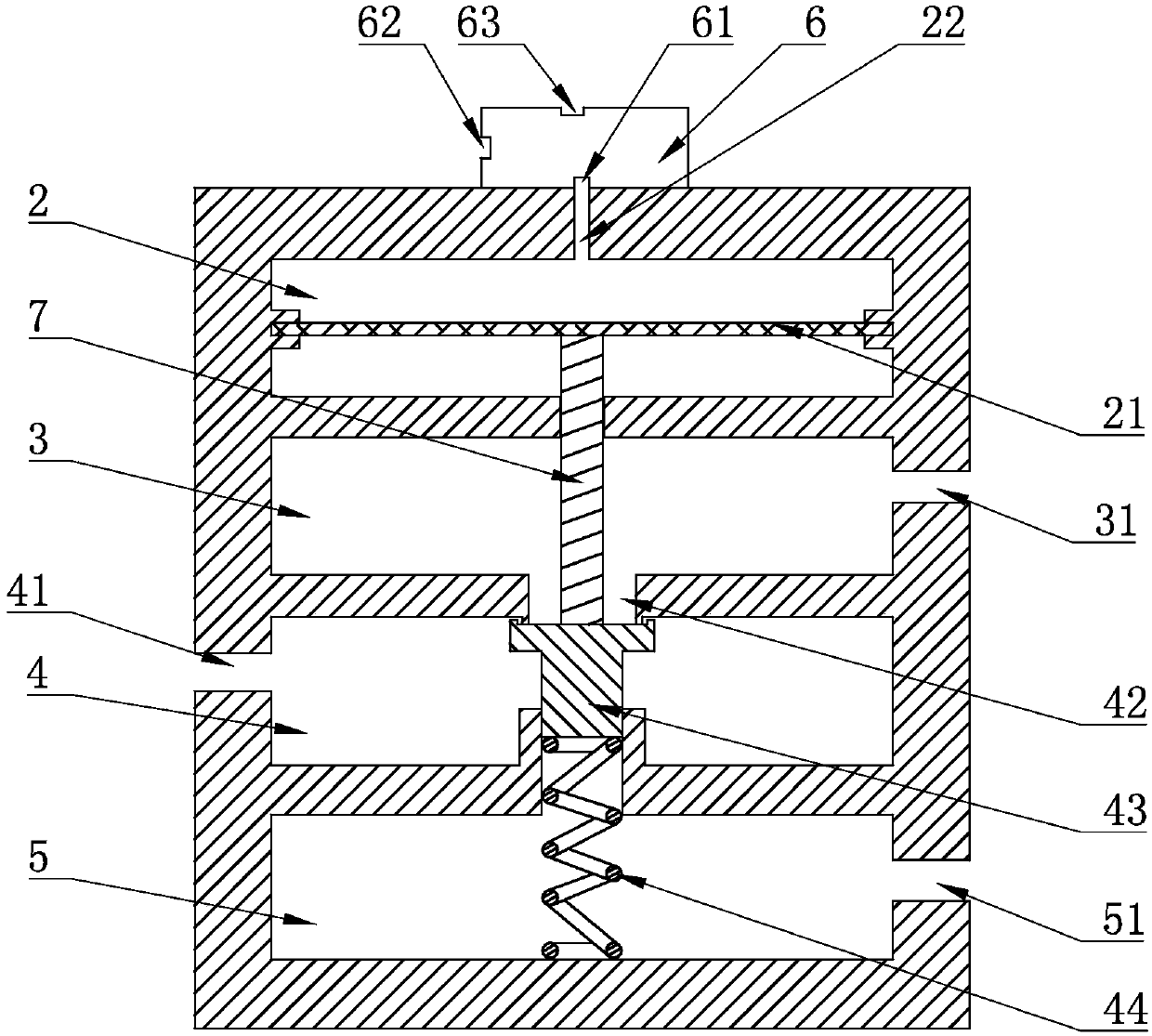

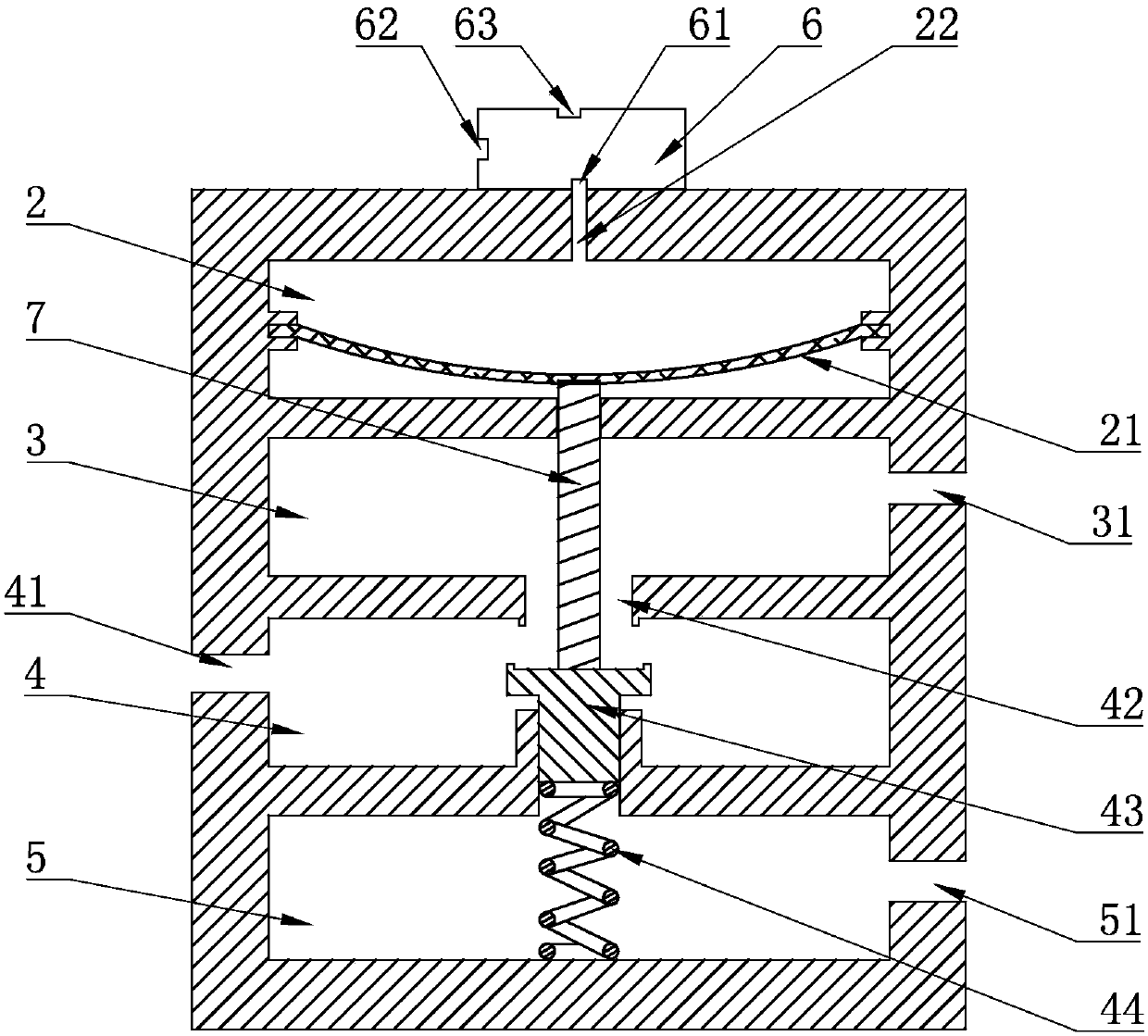

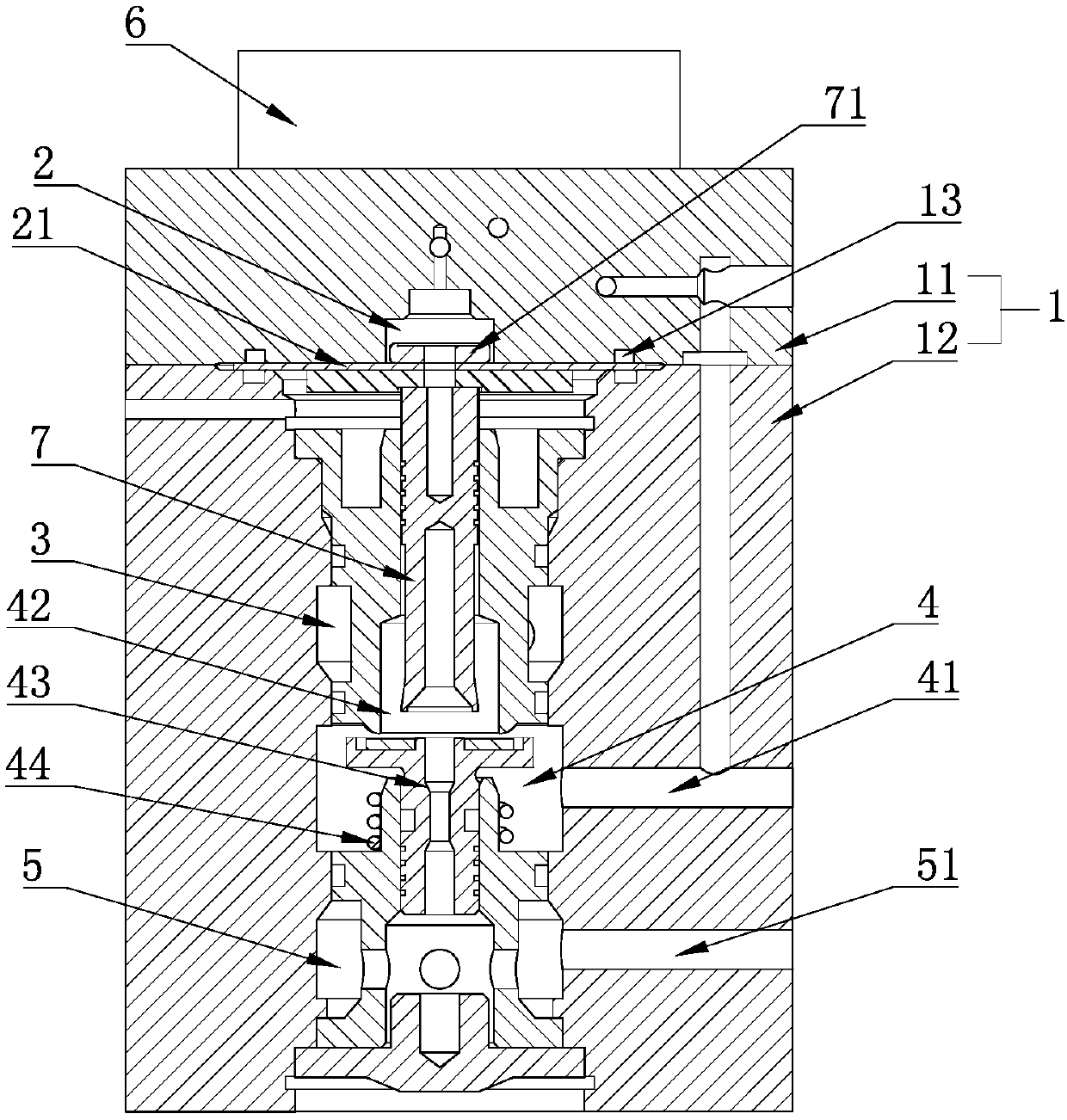

[0026] refer to Figure 1 to Figure 3 An embodiment of a pneumatic proportional valve based on a MEMS microfluidic chip of the present invention will be further described.

[0027] A pneumatic proportional valve based on MEMS microfluidic chip, such as image 3 As shown, the main valve body 1 and the MEMS microfluidic chip 6 arranged on the main valve body 1 are included, and the MEMS microfluidic chip 6 is provided with a gas source port 62, a control port 61 and an exhaust port 63; the main valve body 1. Diaphragm chamber 2, pressure control chamber 3, air source chamber 4 and exhaust chamber 5 are arranged sequentially from top to bottom. Diaphragm 21 made of rubber is arranged in diaphragm chamber 2, and the middle of diaphragm 21 is connected with The spool 7 moves up and down with the diaphragm 21, the spool 7 passes through the diaphragm 21 and is fixed on the diaphragm 21 by the diaphragm splint 71, and the main valve body 1 is provided with an input connecting the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com