Fixed constant velocity joint

A constant velocity joint and fixed technology, which is applied in the field of speed joints, can solve the problems of reduced shared load, increased shared load, and reduced durability of fixed constant velocity joints, so as to ease the change of shared load and improve durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

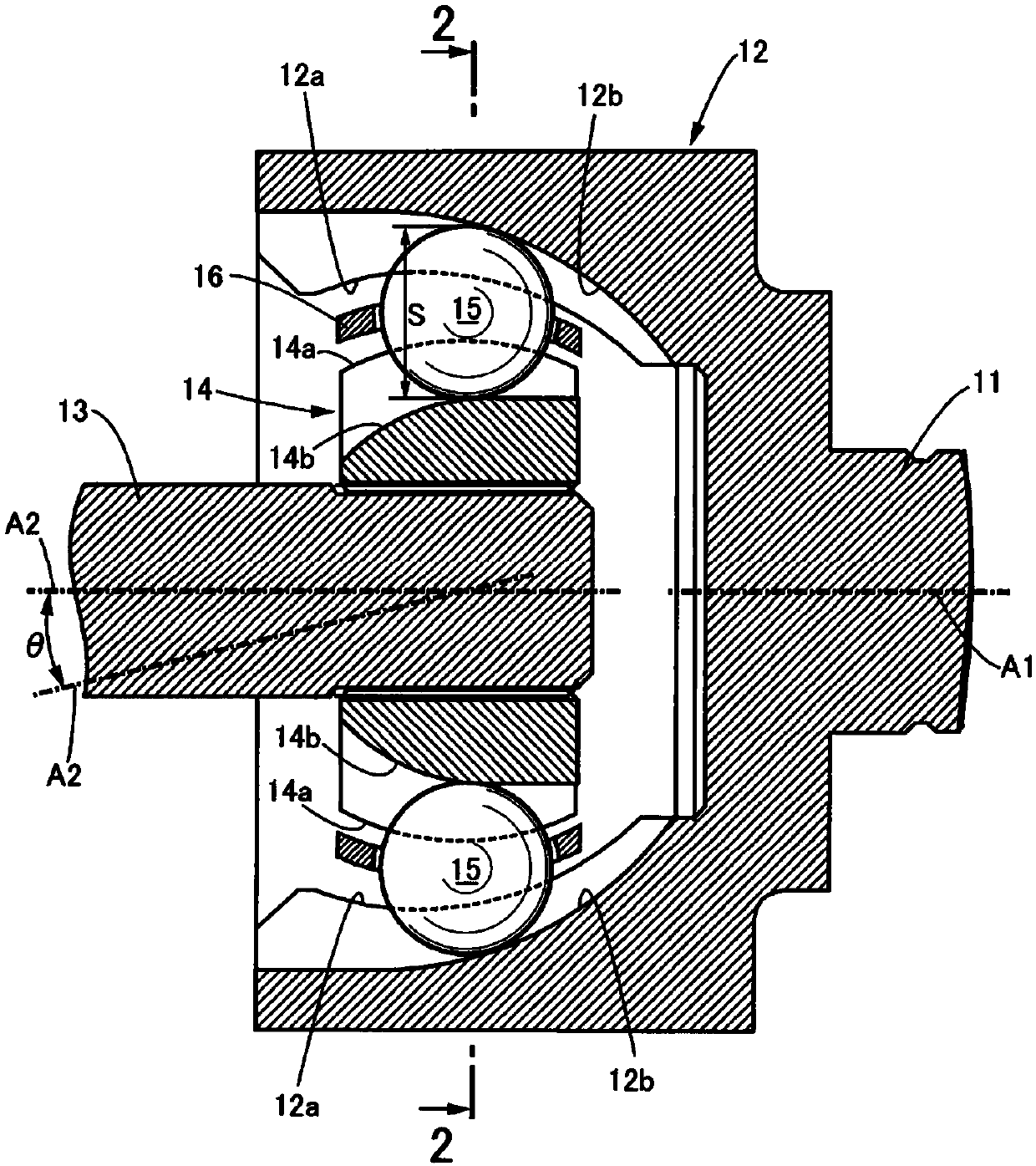

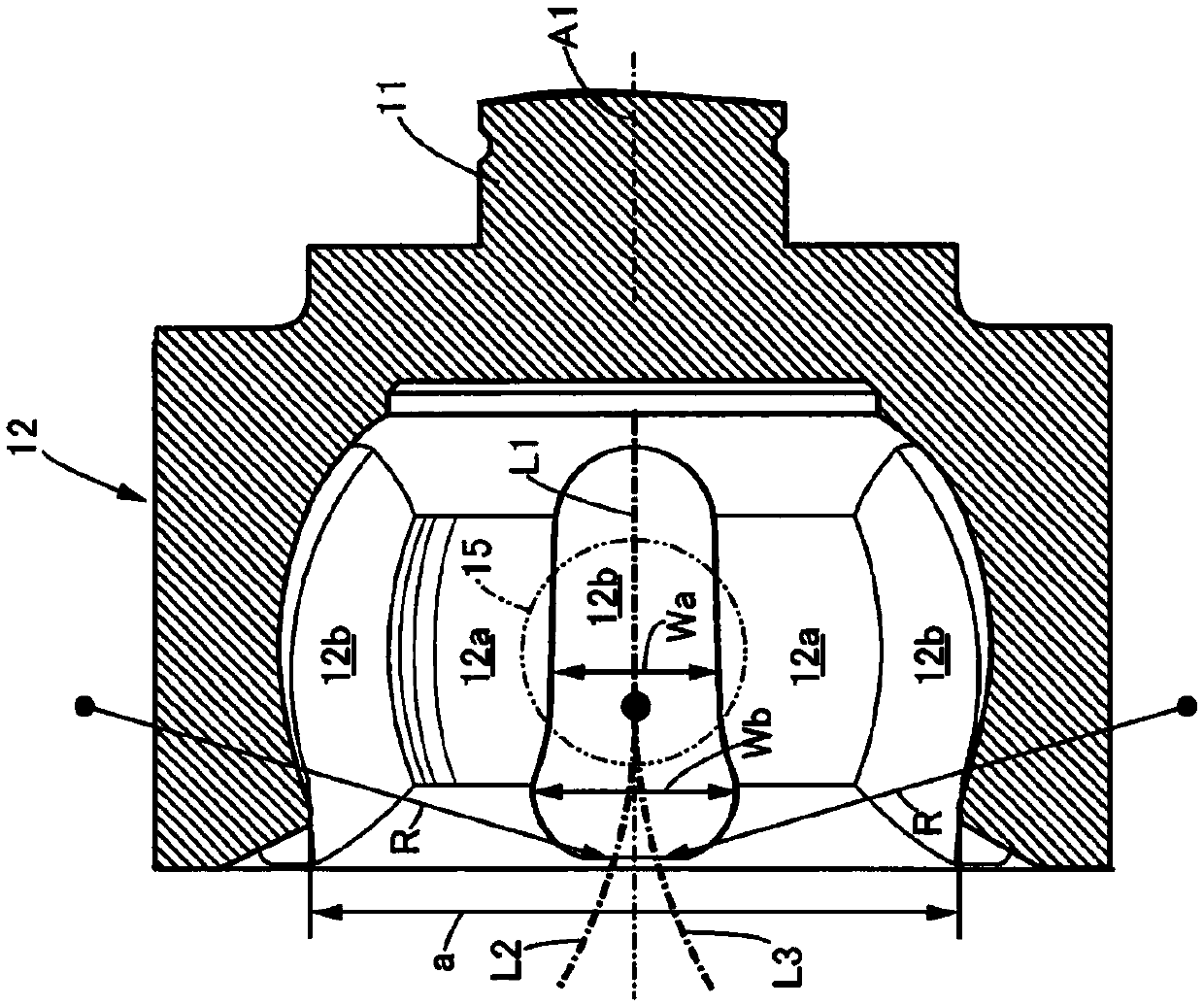

[0031] Below, based on Figure 1 to Figure 5(B) Embodiments of the present invention will be described.

[0032] Such as figure 1 and figure 2 As shown, the fixed constant velocity joint of this embodiment includes an outer member 12 integrally formed with the first rotating shaft 11 and an inner member 14 spline-coupled with the second rotating shaft 13, and the part spherical shape of the inner member 14 The outer peripheral surface 14a of the outer peripheral surface 14a of the first rotary shaft 11 is fitted with a gap with the partially spherical inner peripheral surface 12a of the cup-shaped outer member 12 which is open on the opposite side of the first rotating shaft 11 .

[0033] On the inner peripheral surface 12a of the outer member 12, six inner peripheral track grooves 12b extending in the direction of the axis A1 of the first rotating shaft 11 are formed at intervals of 60° in the circumferential direction. On the outer peripheral surface 14a, six outer peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com