Resistance reduction anti-corrosion outer wrapping body for reinforced concrete beam or column

A technology for reinforced concrete beams and cladding, applied in covering/lining, construction, building structure, etc., can solve the problems of increasing the amount of concrete and the weight of the tower body, high operation and maintenance costs, and expensive paint, etc., and achieves good anti-corrosion effect. , Simple production and assembly, and the effect of reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

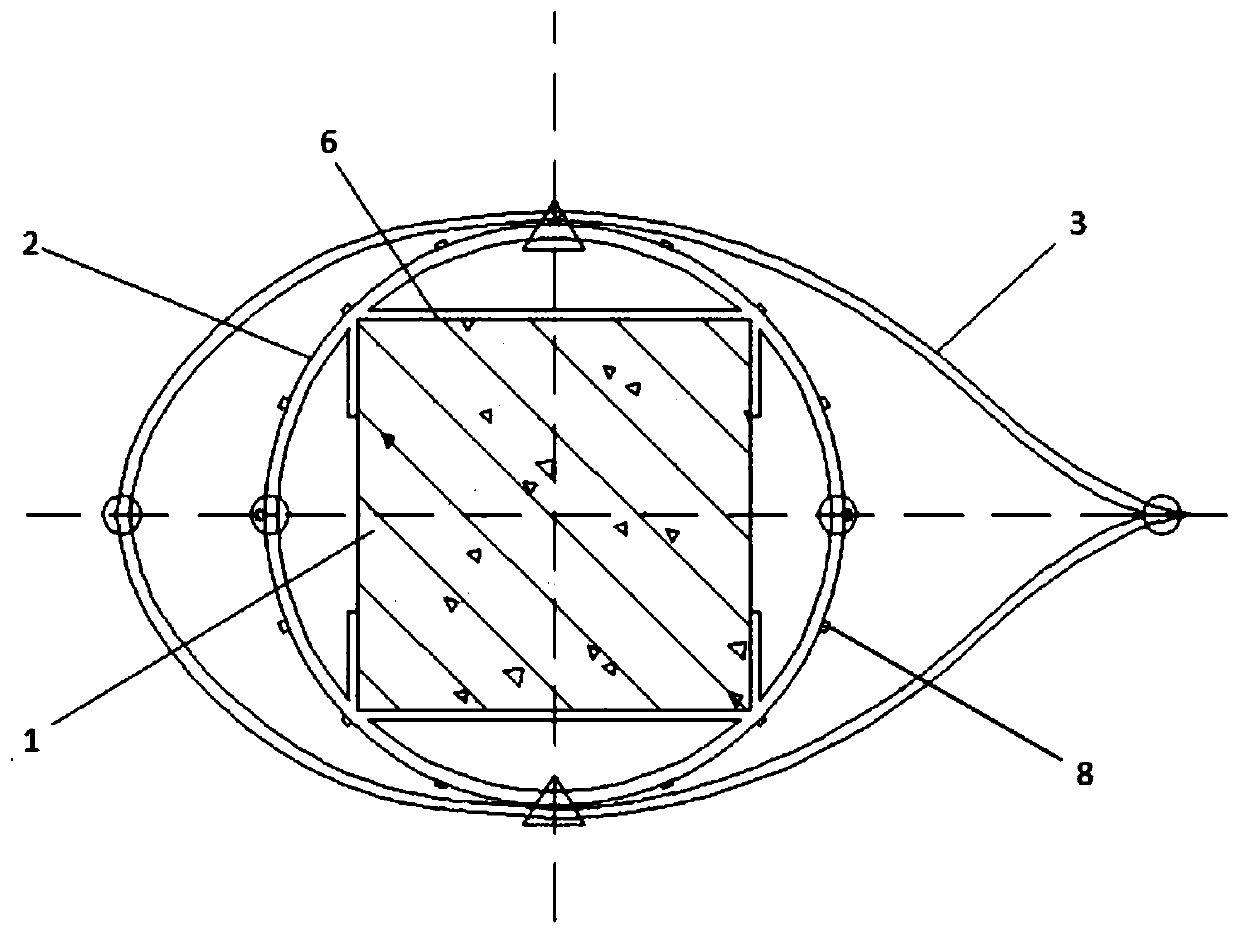

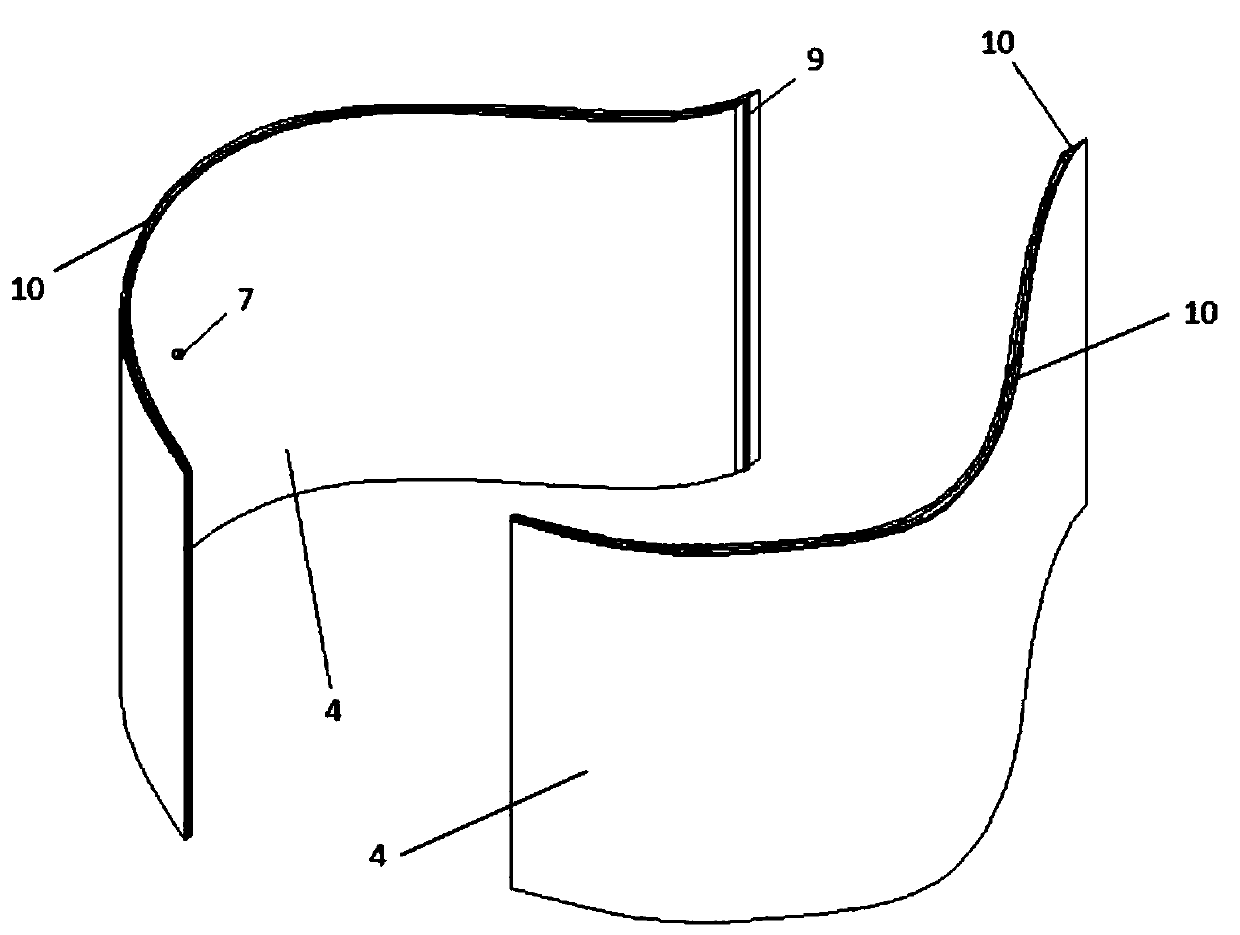

[0046] Such as figure 1 As shown, the resistance-reducing corrosion outer enclosure for reinforced concrete beams / columns 1 with a square cross-section described in this embodiment includes an inner shell 2 with open upper and lower ends and an outer shell 3 with open upper and lower ends. The outer shell 3 is made of hard polyvinyl chloride, and its outer surface is a streamlined hyperbolic cylinder, the front of the hyperbolic cylinder is round and the rear is pointed, and the surface is smooth. The fluid is mainly laminar on the surface of the hyperbolic cylinder, and there is no or There is very little turbulence. The inner housing 2 is coaxially arranged in the outer housing 3 and is connected with the inner housing 2 through an A-shaped tenon-and-mortise structure. The inner housing 2 is an arc plate made of hard polyvinyl chloride. The cross-section of the arc plate is a full circle circumscribed to the cross-section of the reinforced concrete beam / column 1, and the ou...

Embodiment 2

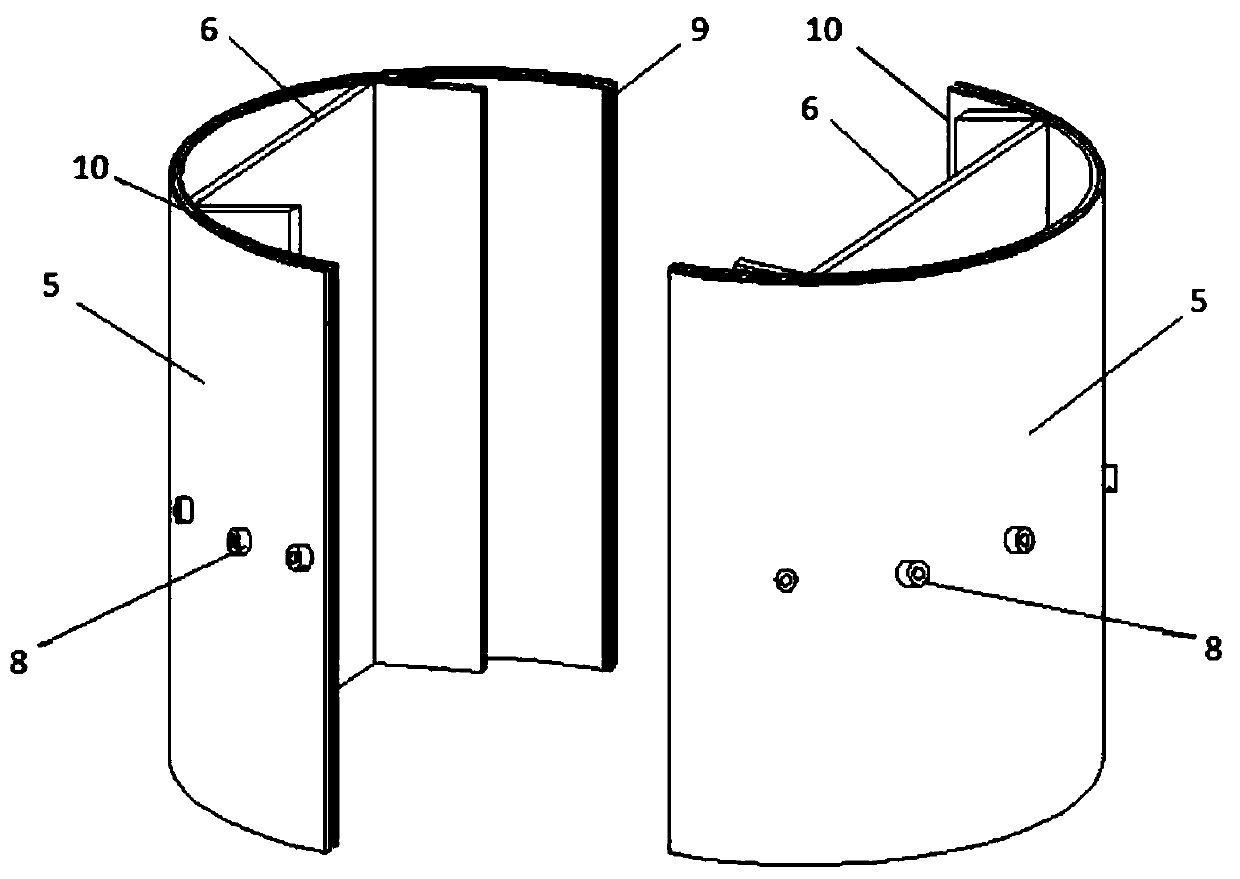

[0052] Such as Figure 6 As shown, the resistance-reducing corrosion outer enclosure for reinforced concrete beams / columns 1 with a square cross-section described in this embodiment includes an inner shell 2 with open upper and lower ends and an outer shell 3 with open upper and lower ends. The outer shell 3 is made of hard polyvinyl chloride, and its outer surface is a streamlined hyperbolic cylinder. The inner shell 2 is coaxially arranged in the outer shell 3 and connected with the inner shell 2 through an A-shaped mortise and tenon structure. , the inner shell 2 is an arc plate made of hard polyvinyl chloride, the section of the arc plate is a full circle circumscribed on the cross section of the reinforced concrete beam / column 1, the inner shell 2 The outer surface of the outer surface is provided with T-shaped guide grooves 12 along the circumference, and two symmetrically arranged notch clips 6 are fixed inside the inner shell 2, which are respectively stuck on the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com