Polyester pre-oriented yarn production equipment

A technology of production equipment and spinning machine, which is applied in the field of POY yarn production equipment, can solve problems such as the limitation of POY yarn production efficiency, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

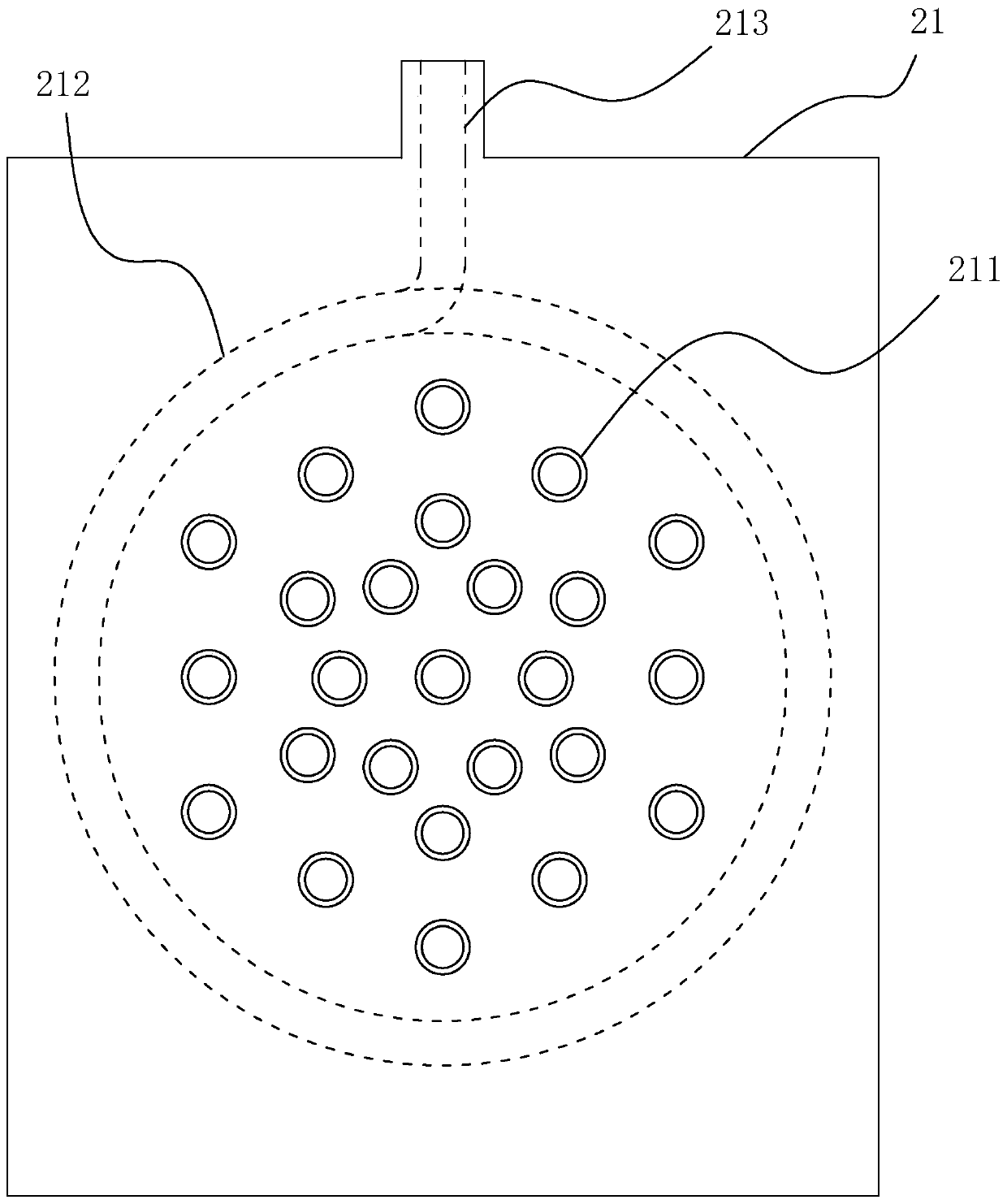

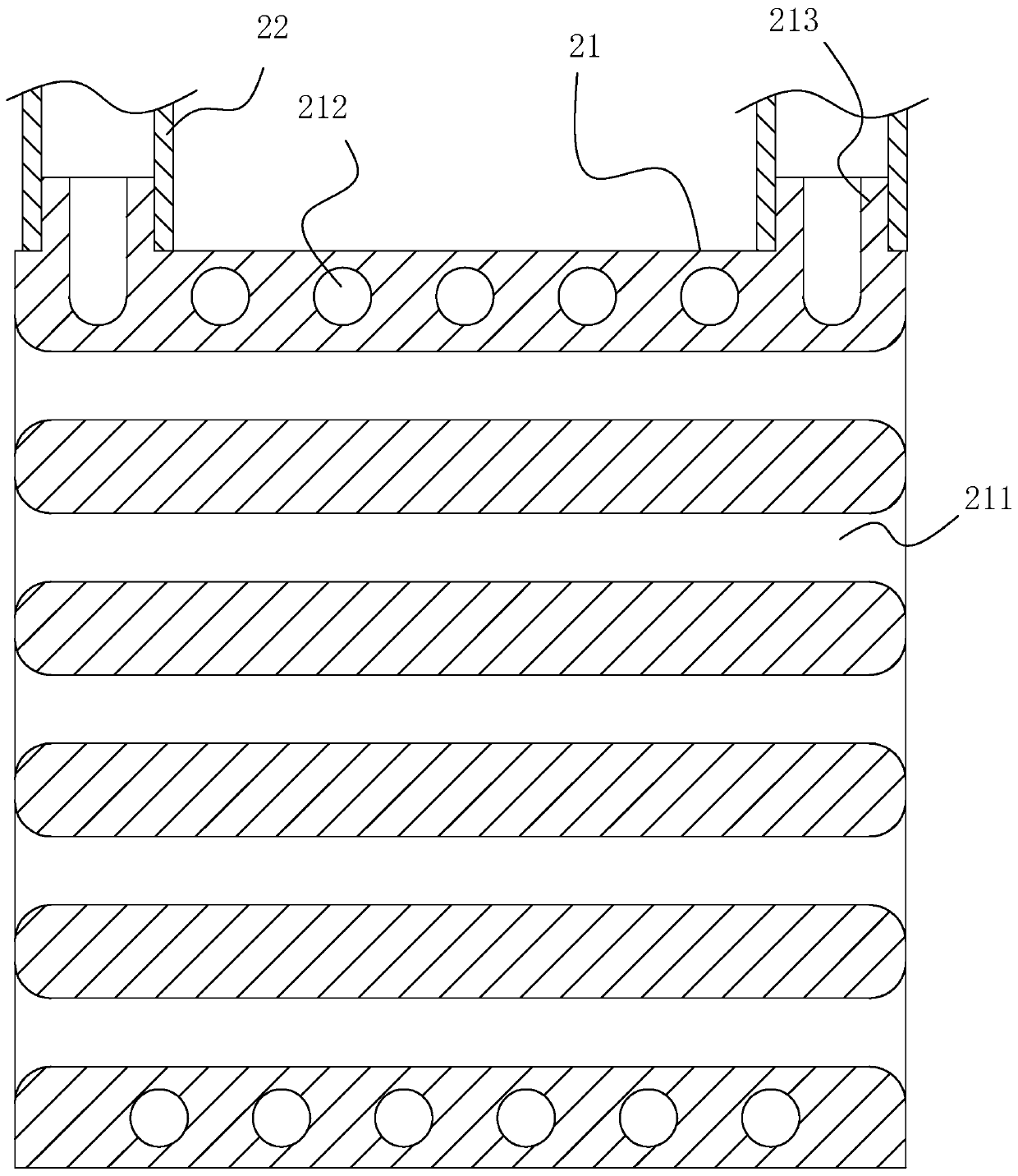

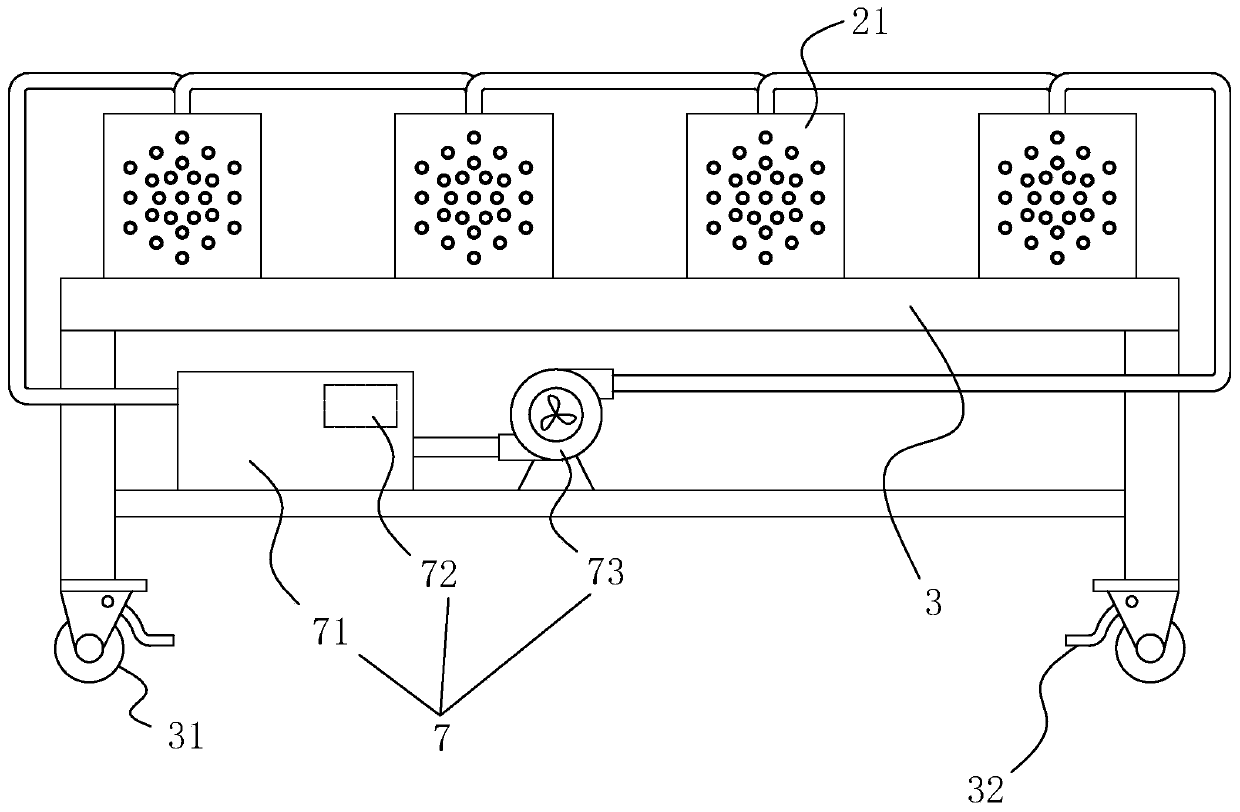

[0034] A kind of POY silk production equipment, such as figure 1 As shown, it includes a plurality of screw extrusion spinning machines 1 arranged side by side for extruding POY filaments, and one piece is arranged at the outlet of each screw extrusion spinning machine 1 for extruding each bundle of POY filaments. A metal cooling part 2 for separation and preliminary cooling, a bracket 3 arranged at the outlet of each screw extrusion spinning machine 1 and located below the metal cooling part 2 for raising the working height of the metal cooling part 2 , multiple ring blowing devices corresponding to the position of each screw extrusion spinning machine 1 and located on the side of the metal cooling member 2 away from each screw extrusion spinning machine 1 for further cooling of each bundle of POY filaments 4. The tunnel 5 arranged on the side of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com