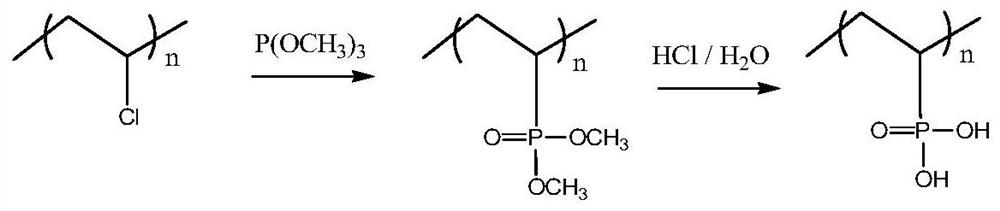

A kind of polyvinyl phosphoric acid and preparation method thereof

A polyvinyl phosphoric acid and phosphoric acid ester technology, applied in the field of functional polymers, can solve the problems of low content of functional groups, difficult handling, complicated processes, etc., and achieve the effects of high content of functional groups, simple process preparation and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of polyvinyl phosphoric acid, concrete steps are:

[0036] (1) Add 10g of PVC into the reaction kettle, then add 50g of phosphoric acid ester and 100g of solvent in sequence, then raise the temperature to 80°C for 24h to obtain the reaction solution;

[0037] The amount of PVC, solvent and phosphoric acid ester used in the above-mentioned reaction is calculated by mass ratio, that is, PVC: phosphoric acid ester: solvent is calculated in a ratio of 1:5:10;

[0038] The phosphoric acid ester is trimethyl phosphite;

[0039] Described solvent is 2-methyltetrahydrofuran;

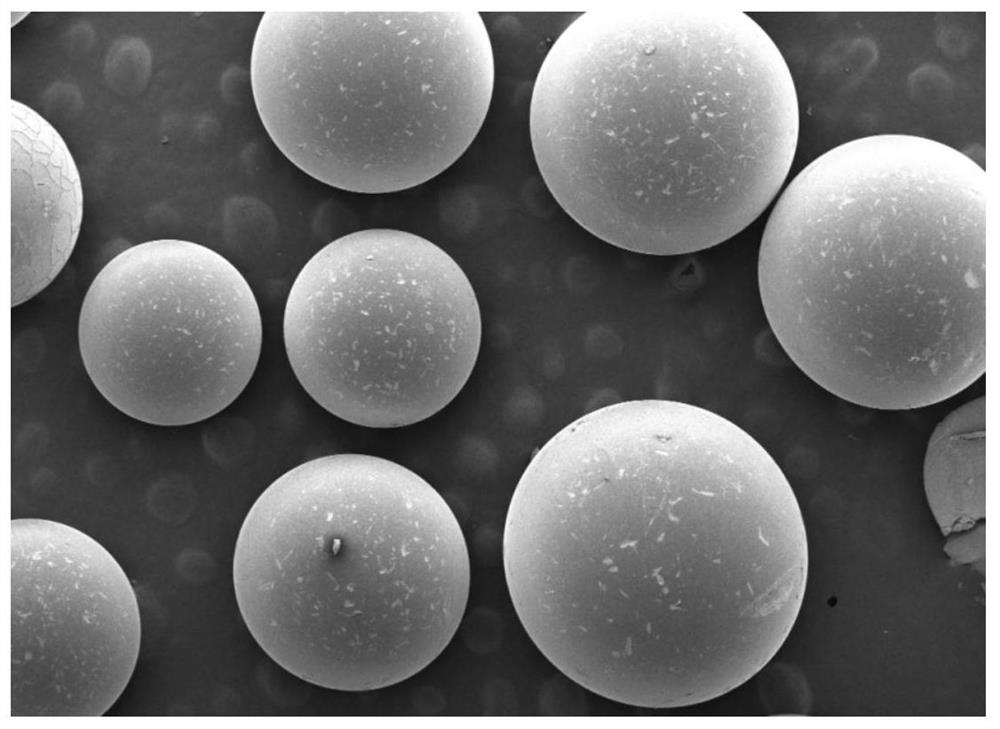

[0040] The PVC is cross-linked polyvinyl chloride microspheres with a particle size of 100-300 μm, produced by Shanghai Qingyuan Resin Co., Ltd.;

[0041] (2), the reaction solution of step (1) gained is filtered, and the filter cake of gained is washed 3 times with ethanol and distilled water respectively successively, and the filter cake obtained is phosphoric acid ester r...

Embodiment 2

[0047] A kind of preparation method of polyvinyl phosphoric acid, concrete steps are:

[0048] (1) Add 10g of PVC to the reaction kettle, then add 60g of phosphoric acid ester and 200g of solvent in sequence, then raise the temperature to 100°C for 24h to obtain the reaction solution;

[0049] The amount of PVC, solvent and phosphoric acid ester used in the above-mentioned reaction is calculated by mass ratio, that is, PVC: phosphoric acid ester: solvent is calculated in a ratio of 1:6:20;

[0050] The phosphoric acid ester is trimethyl phosphite;

[0051] Described solvent is sherwood oil;

[0052] The PVC is cross-linked polyvinyl chloride microspheres with a particle size of 100-300 μm, produced by Shanghai Qingyuan Resin Co., Ltd.;

[0053] (2), the reaction solution of step (1) gained is filtered, and the filter cake of gained is washed 3 times with ethanol and distilled water respectively successively, and the filter cake obtained is phosphoric acid ester resin;

[00...

Embodiment 3

[0060] A kind of preparation method of polyvinyl phosphoric acid, concrete steps are:

[0061] (1) Add 10g of PVC to the reaction kettle, then add 60g of phosphoric acid ester and 300g of solvent in sequence, then raise the temperature to 80°C for 36h to obtain the reaction solution;

[0062] The amount of PVC, solvent and phosphoric acid ester used in the above-mentioned reaction is calculated by mass ratio, that is, PVC: phosphoric acid ester: solvent is calculated in a ratio of 1:6:30;

[0063] The phosphoric acid ester is trimethyl phosphite;

[0064] Described solvent is 2-methyltetrahydrofuran;

[0065] The PVC is cross-linked polyvinyl chloride microspheres with a particle size of 100-300 μm, produced by Shanghai Qingyuan Resin Co., Ltd.;

[0066] (2), the reaction solution of step (1) gained is filtered, and the filter cake of gained is washed 3 times with respectively ethanol and distilled water successively, and the filter cake obtained is phosphoric acid ester res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com