Preparation of low-shrinkage UPy-ionic liquid mixed type photocuring monomer

A light-curing monomer and ionic liquid technology, applied in the field of light-curing, can solve the problems of poor compatibility with light-curing monomers and initiators, hindering application, etc. easy precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation of low-shrinkage UPy ionic liquid mixed type photocurable monomer, the preparation method of this mixed monomer comprises the steps:

[0040] (1) Preparation method of UPy monomer

[0041] ①Heat 1.25g 6-methylisocytosine and 25g DMSO at 150°C for 0.8h, stir to form a clear solution;

[0042] ② Then in N 2 Under protective conditions, slowly add 1.31g of isocyanoethyl methacrylate dropwise, and stir at 20°C for 0.5h; then put the reaction bottle into an ice-water bath to terminate the reaction, and a lot of white solids will be produced;

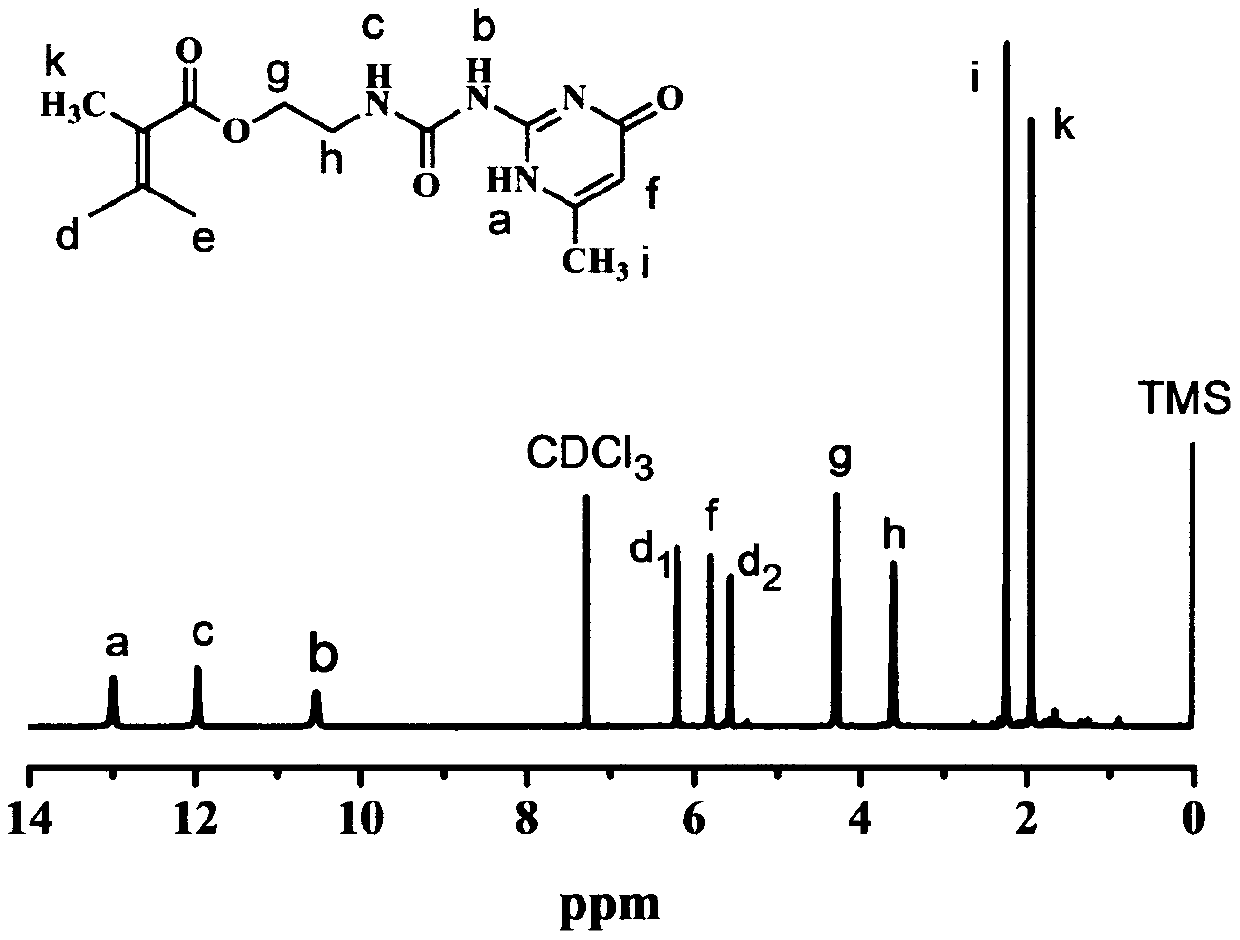

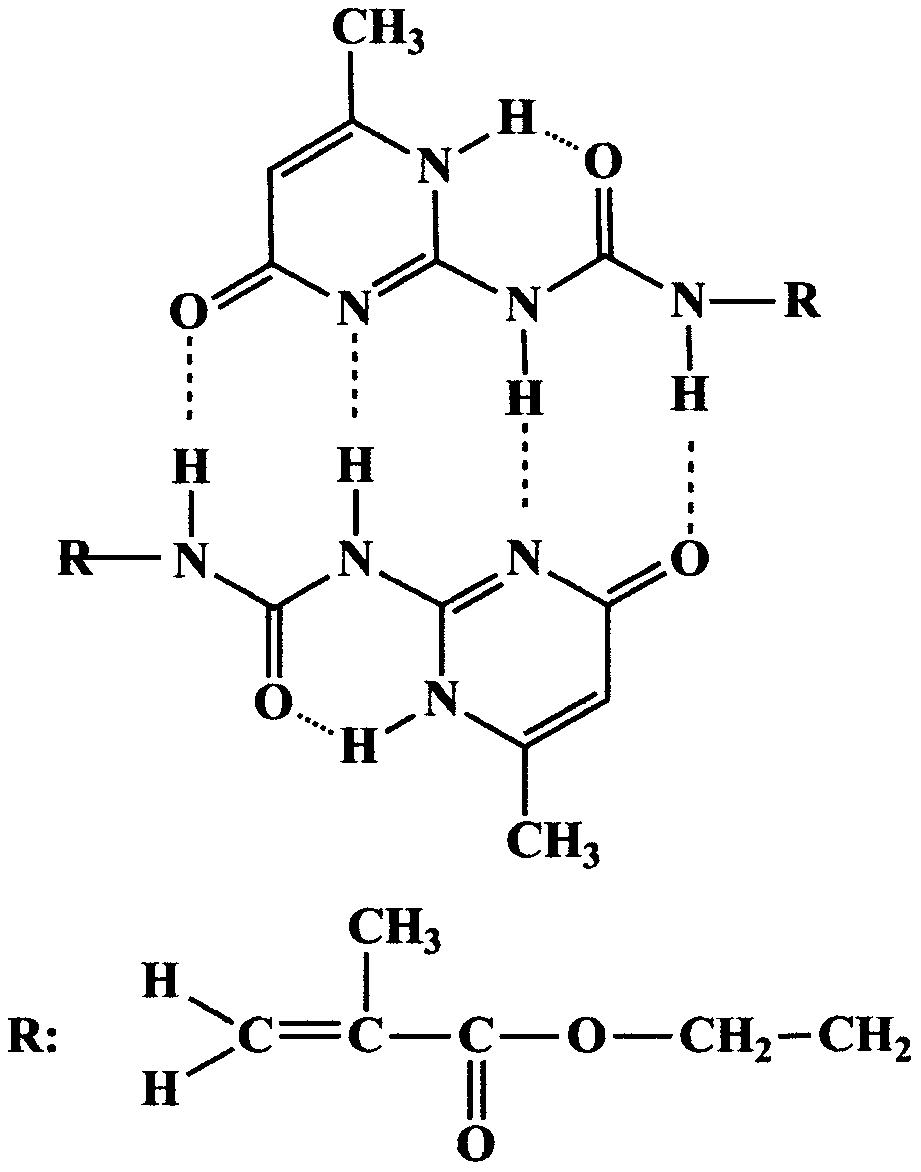

[0043] ③Finally wash 3 times with acetone to remove the remaining reactants and solvent, and filter and dry to obtain powdered 2-(3-(6-methyl-4-oxo-1,4-dihydropyrimidine ) ureido) ethyl methacrylate. Its NMR spectrum is as figure 1 As shown, its hydrogen bond network diagram is shown in figure 2 shown.

[0044] (2) Preparation of double bond-containing ionic liquid

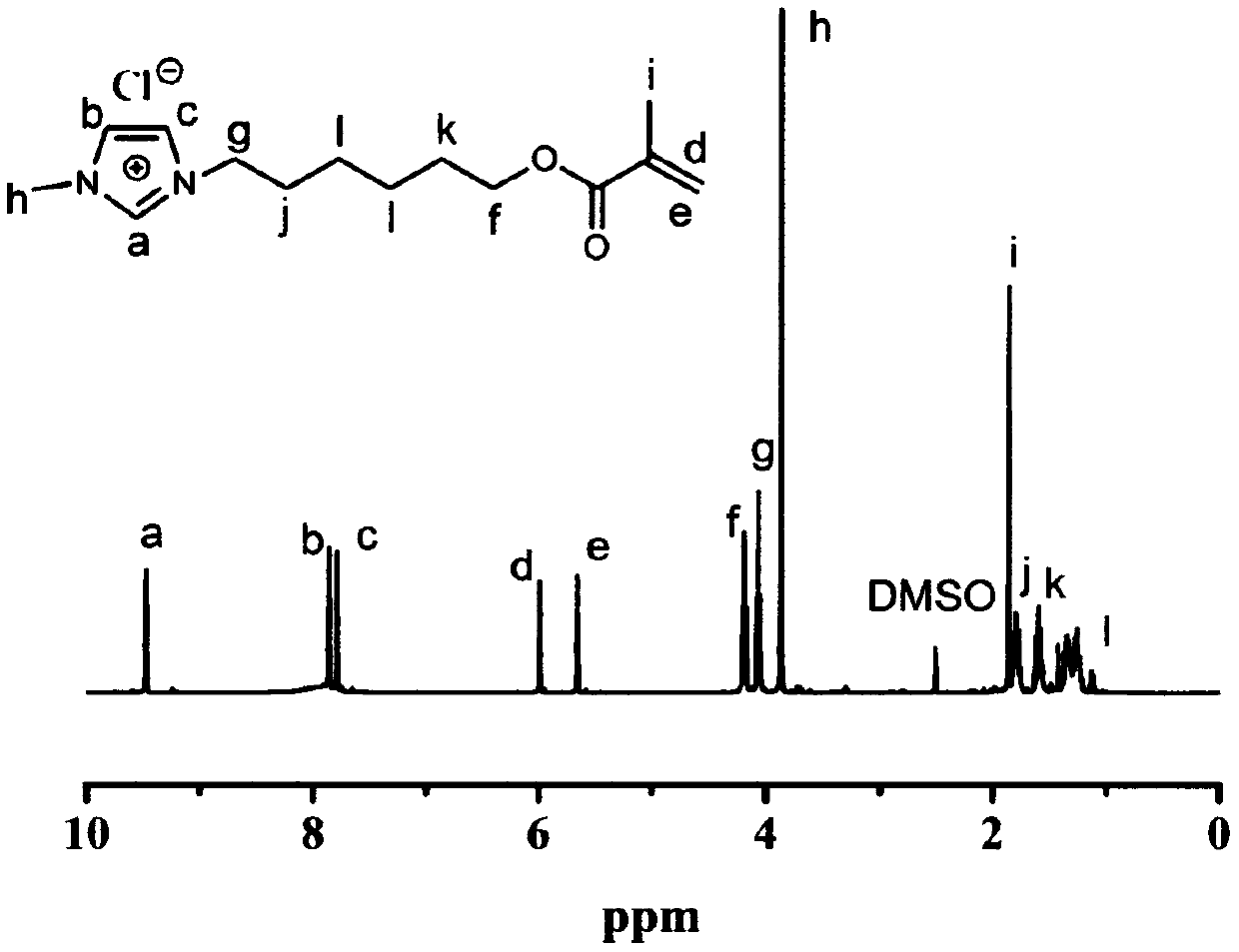

[0045] ① First, mix 4.10g 1-methylimida...

Embodiment 2

[0054] A kind of preparation of low-shrinkage UPy ionic liquid mixed type photocurable monomer, the preparation method of this mixed monomer comprises the steps:

[0055] (1) Preparation method of UPy monomer

[0056] ①Heat 1.25g 6-methylisocytosine and 31.25g DMSO at 135°C for 0.6h, stir to form a clear solution;

[0057] ② Then in N 2 Under protective conditions, 2.13 g of isocyanobutyl ethacrylate was slowly added dropwise, and the reaction was stirred at 30°C for 0.8 h; then the reaction bottle was placed in an ice-water bath to terminate the reaction, and a lot of white solids would be produced.

[0058] ③Finally wash with acetone 4 times to remove residual reactant and solvent, and filter and dry to obtain powdered (2-(3-(6-methyl-4-oxo-1,4-dihydro pyrimidine) ureido) butyl ethyl acrylate.

[0059] (2) Preparation of double bond-containing ionic liquid

[0060] ①First, mix 4.80g 1-ethylimidazole with 14.43g 6-bromo-n-hexanol, N 2 Under protective conditions, stir an...

Embodiment 3

[0069] A kind of preparation of low-shrinkage UPy ionic liquid mixed type photocurable monomer, the preparation method of this mixed monomer comprises the steps:

[0070] (1) Preparation method of UPy monomer

[0071] ①Heat 1.25g 6-methylisocytosine and 37.5g DMSO at 140°C for 0.45h, stir to form a clear solution;

[0072] ② Then in N 2 Under protective conditions, 2.01 g of isocyanobutyl methacrylate was slowly added dropwise, and the reaction was stirred at 35°C for 1 h; then the reaction bottle was put into an ice-water bath to terminate the reaction, and a lot of white solids would be produced.

[0073] ③Finally wash 5 times with acetone to remove residual reactant and solvent, and filter and dry to obtain powdered (2-(3-(6-methyl-4-oxo-1,4-dihydro pyrimidine) ureido) butyl methacrylate.

[0074] (2) Preparation of double bond-containing ionic liquid

[0075] ① First, mix 5.60g 1-propylimidazole with 20.39g 6-iodo-n-hexanol, N 2 Under protective conditions, stir and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com