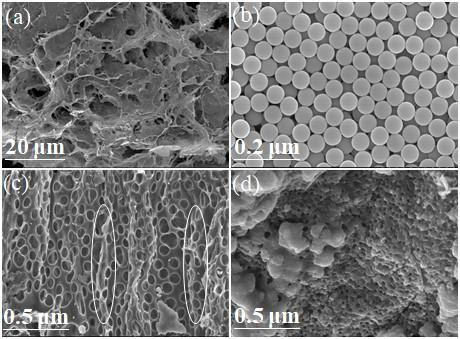

Preparation method and application of three-dimensional ordered macro-porous alpha-Fe2O3/graphene aerogel electrode

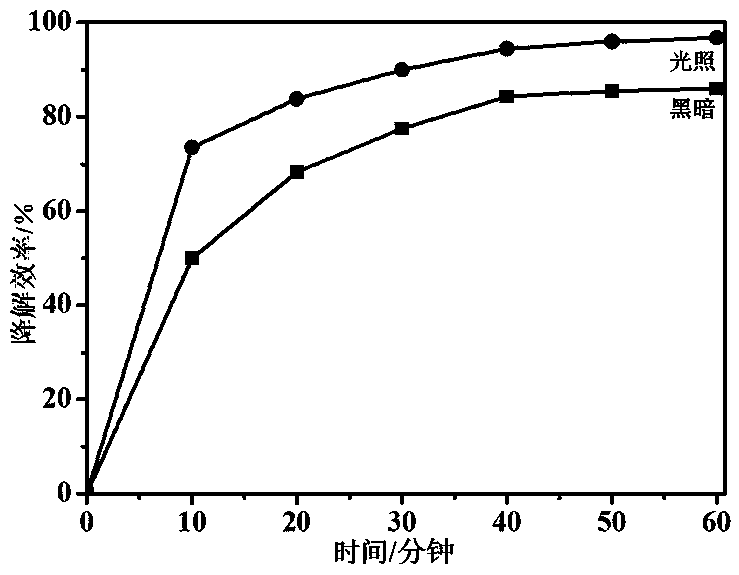

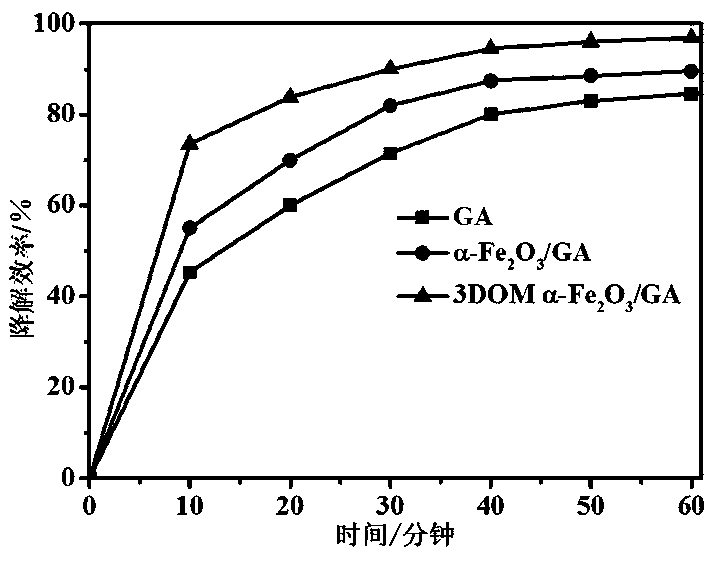

A graphene airgel, three-dimensional ordered technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of low quantum efficiency, photocatalytic activity limitation, etc., and achieve high ratio Surface area, increased degradation efficiency, improved mass transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1. Preparation of graphene airgel:

[0031] Ultrasonic disperse the graphene oxide to obtain a graphene oxide dispersion, the concentration of the graphene oxide dispersion is 12 mg / L, adjust the pH to 9 with ammonia water, ultrasonically disperse for 2 hours, add 0.2 mL EDTA after ultrasonication, stir evenly, and continue ultrasonication for 4 hours h, after the ultrasonication, react the uniformly dispersed mixture at 180 °C for 14 h to obtain a graphene hydrogel, place it in 50 mL of low-concentration ethanol solution for solvent replacement, let it stand for 6 h, and store it at -10 °C Cool down for 12 h and dry naturally for 24 h to obtain graphene airgel (GA);

[0032] Step 2. Self-assembly of polystyrene hard template:

[0033] A monodisperse polystyrene microsphere emulsion with a diameter of 500 nm and a mass concentration of 0.5% was placed in distilled water, the volume ratio of the emulsion to deionized water was 0.5:3, and ultrasonically dispersed fo...

Embodiment 2

[0037] Step 1. Preparation of graphene airgel:

[0038] Ultrasonic disperse the graphene oxide to obtain a graphene oxide dispersion, the concentration of the graphene oxide dispersion is 12 mg / L, adjust the pH to 9 with ammonia water, ultrasonically disperse for 2 h, add 0.2 m L EDTA after ultrasonication, stir evenly, and continue ultrasonication 4 h, after the end of ultrasonication, the uniformly dispersed mixture was reacted at 180 °C for 14 h to obtain a graphene hydrogel, which was placed in 50 mL of low-concentration ethanol solution for solvent replacement, allowed to stand for 6 h, and cooled at -10 Cool at ℃ for 12 h, and dry naturally for 24 h to obtain graphene airgel (GA);

[0039] Step 2. Self-assembly of polystyrene hard template:

[0040] A monodisperse polystyrene microsphere emulsion with a diameter of 500 nm and a mass concentration of 0.5% was placed in distilled water, the volume ratio of the emulsion to deionized water was 0.5:3, and ultrasonically disp...

Embodiment 3

[0044] Step 1. Preparation of graphene airgel:

[0045] Ultrasonic disperse the graphene oxide to obtain a graphene oxide dispersion, the concentration of the graphene oxide dispersion is 12 mg / L, adjust the pH to 9 with ammonia water, ultrasonically disperse for 2 hours, add 0.2 mL EDTA after ultrasonication, stir evenly, and continue ultrasonication for 4 hours h, after the ultrasonication, react the uniformly dispersed mixture at 180 °C for 14 h to obtain a graphene hydrogel, place it in 50 mL of low-concentration ethanol solution for solvent replacement, let it stand for 6 h, and store it at -10 °C Cool down for 12 h and dry naturally for 24 h to obtain graphene airgel (GA);

[0046] Step 2. Self-assembly of polystyrene hard template:

[0047] A monodisperse polystyrene microsphere emulsion with a diameter of 500 nm and a mass concentration of 0.5% was placed in distilled water, the volume ratio of the emulsion to deionized water was 0.5:3, and ultrasonically dispersed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com