Automatic clay-mine cleaning device for ore carrying belt of heavy plate machine

An automatic cleaning and trigger technology, applied in the field of mine transportation equipment, can solve the problems of many bearing failures, heavy load, insufficient bearing strength, etc., achieve good wear resistance and interchangeability, reduce machine vibration, and machine vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

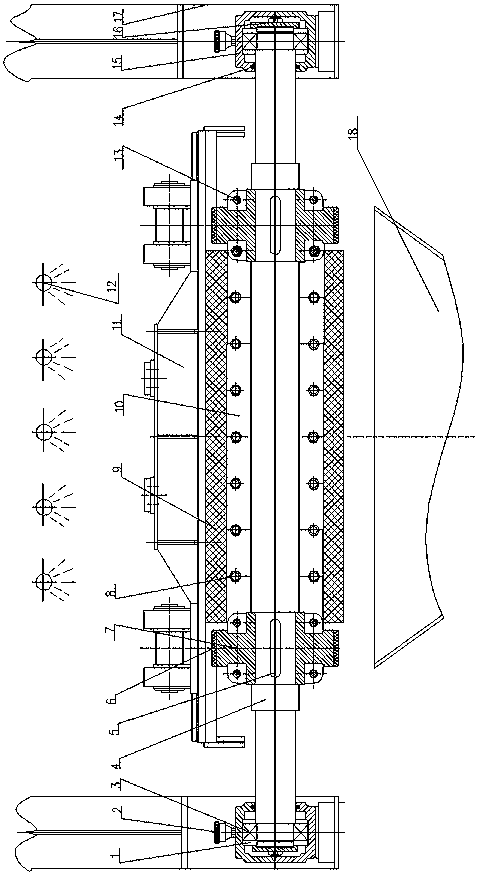

[0036] Such as figure 1As shown, a device for automatic cleaning of mud ore on the ore belt of a heavy plate machine is characterized in that it includes a lower support shaft 4, the two ends of the lower support shaft 4 are fixed by rolling bearings 3, the rolling bearings 4 cooperate with bearing housings 15, and the bearing housings 15 are fixed on rack 17;

[0037] The ore transport belt 11 is located above the lower support shaft 4, and the two do not touch each other. A connecting plate 10 is arranged in the middle of the lower supporting shaft 4. Four connecting plates 10 are evenly arranged along the outer circumferential direction of the shaft. On both sides of the connecting plate 10, respectively A support ring 7 is provided, and the support ring 7 is in contact with the bottom of the ore transport belt 11, and is used to support the ore transport belt 11 and the connecting plate 10; each connecting plate is evenly provided with fixing bolts for fixing the wire brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com