Rotatable maintenance device for concrete test block

A concrete test block and curing box technology, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of cumbersome maintenance work, troublesome test block storage and removal, etc., to avoid excessive dependence and facilitate storage and removal, storage and removal. Easy and fast work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

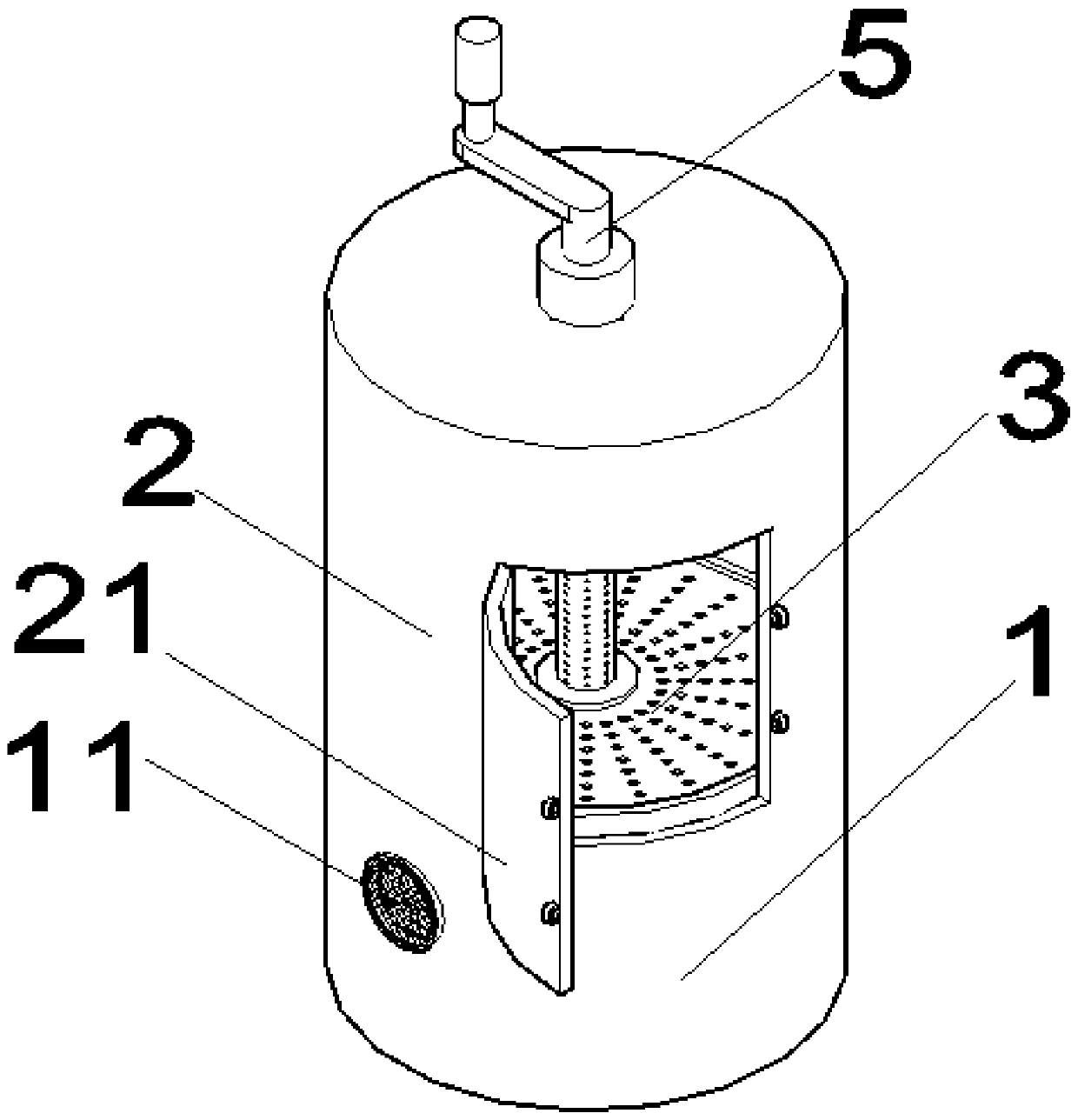

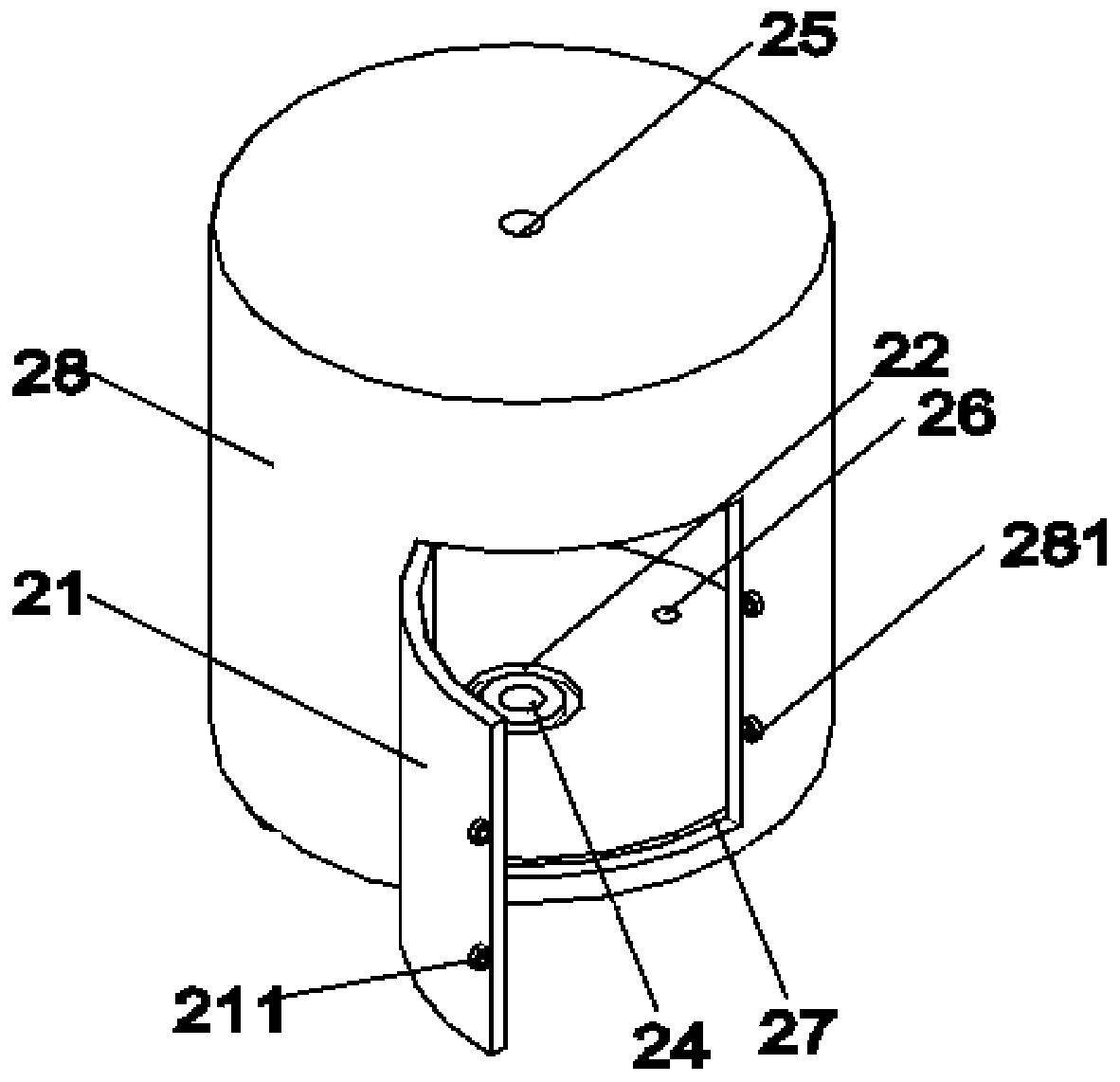

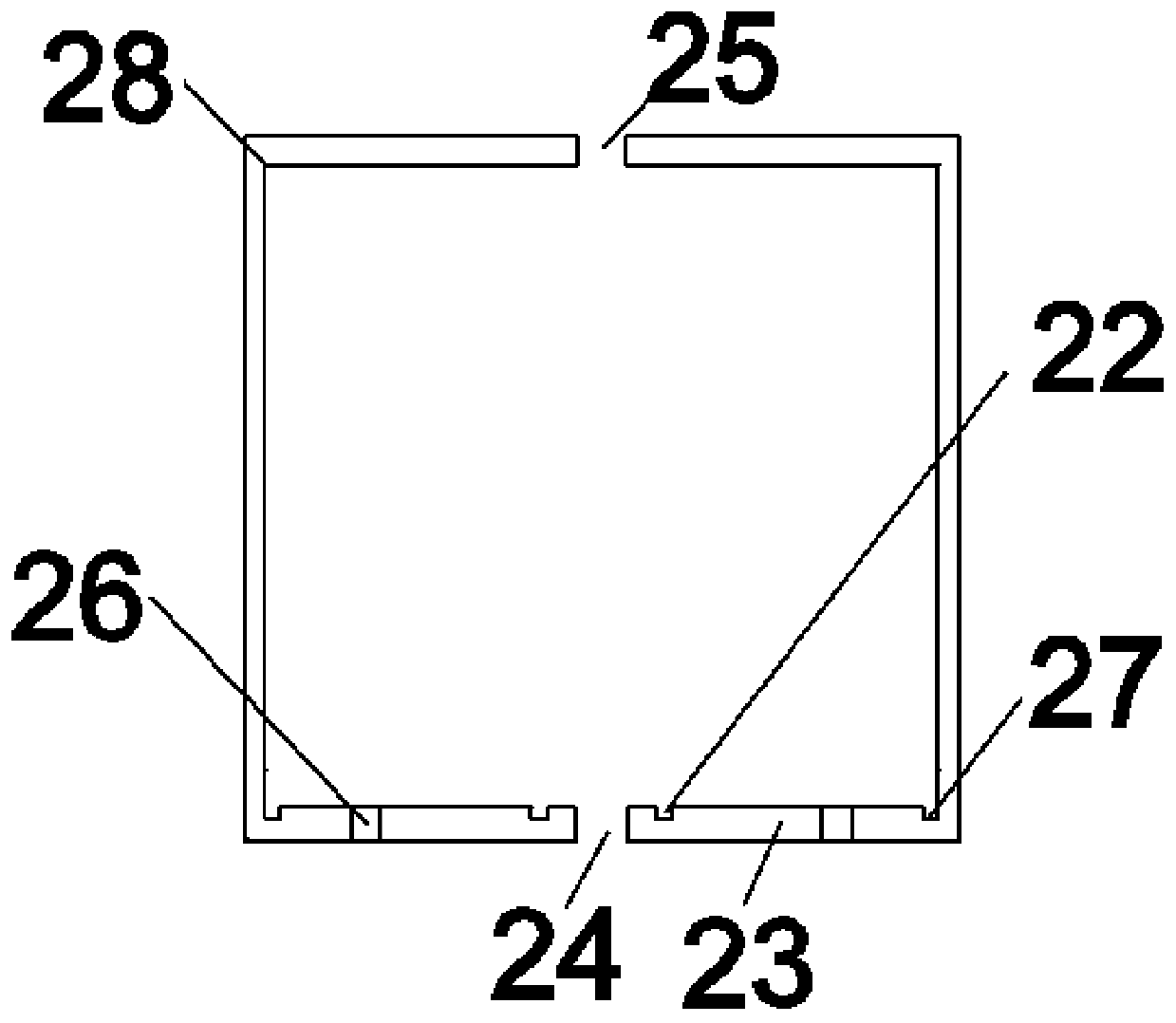

[0037] Such as Figure 1-Figure 8 As shown, the present invention includes the following characteristic components: 1 is a humidification cavity, 2 is a maintenance cavity, 3 is a humidification bracket, 4 is a rotating shaft, 5 is a rotating handle, 11 is a fan, 14 is water, and 15 is a floating Ball, 16 is a high-frequency ultrasonic generator, 17 is a solenoid valve, 18 is a water inlet pipe, 19 is a water inlet, 21 is a box door, 211 is a circular ring box door jack, 22 is an inner rotating track, and 23 is the middle Plate, 24 is a ventilation hole, 25 is a shaft hole, 26 is a drainage hole, 27 is an outer rotating track, 28 is a maintenance cavity shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com