A multi-mirror laser precision splicing calibration method

A calibration method and precision technology, applied in the direction of instrumentation, improvement of process efficiency, calculation, etc., can solve the problems of poor splicing accuracy, long time consumption, and difficulty in one-time completion, so as to avoid secondary errors and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

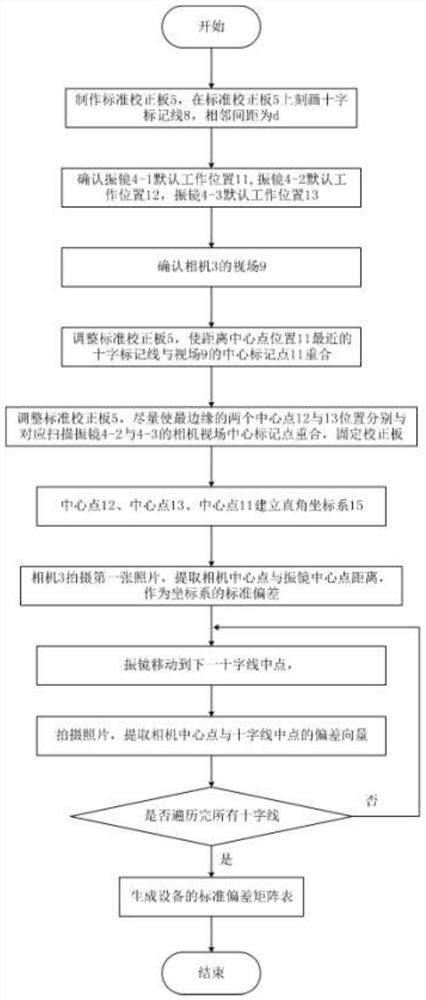

[0035] A multi-mirror laser precision splicing calibration method of the present invention, such as figure 1 As shown, the specific steps are as follows:

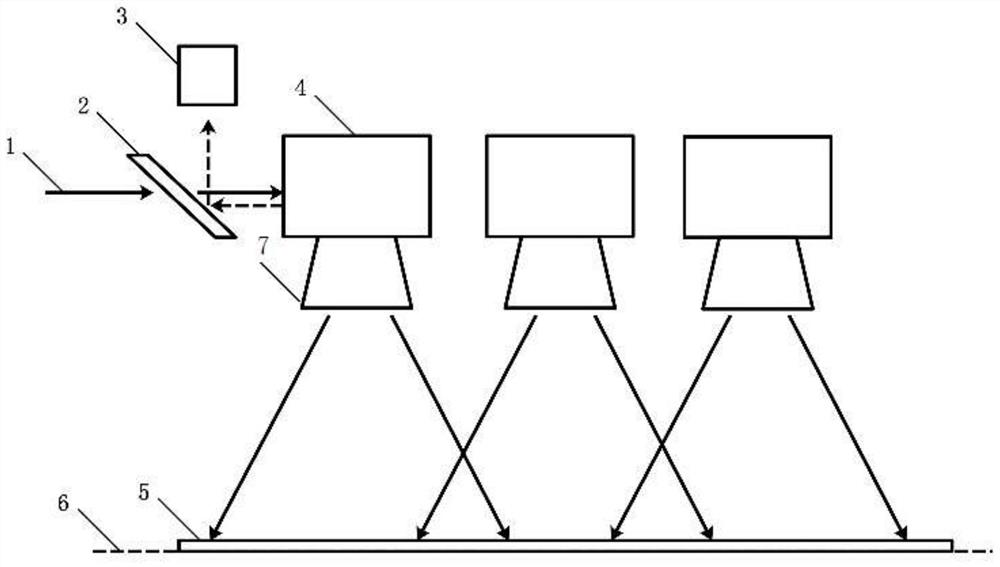

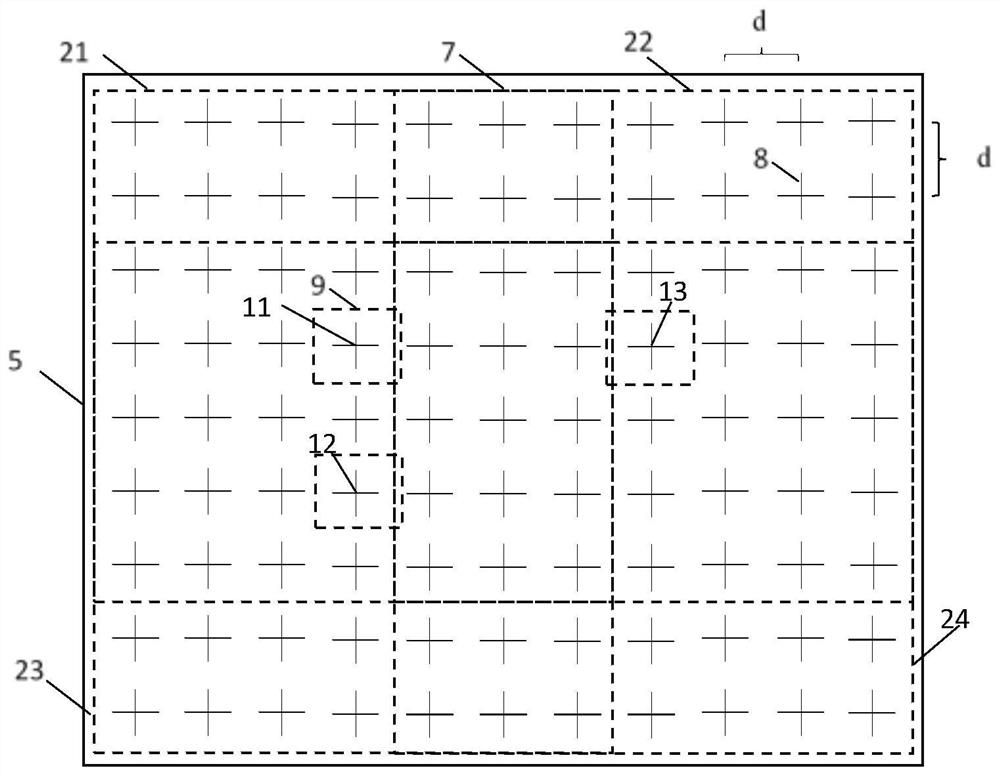

[0036] Step 1. Build a multi-mirror laser precision splicing calibration table, such as figure 2 As shown, the specific structure is as follows:

[0037] It includes a correction plate arranged on the working plane 6, a number of field lenses 7 arranged in sequence at a certain distance on the top of the correction plate, and a scanning galvanometer 4 is correspondingly arranged on the upper part of each field lens 7, and several scanning galvanometers 4 are located in the laser beam 1 laser On the straight line of the emission direction, a half mirror 2 is arranged obliquely along the laser emission direction, the center of the half mirror 2 and the scanning vibrating mirror 4 are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com